Polyethylene Blown Film Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

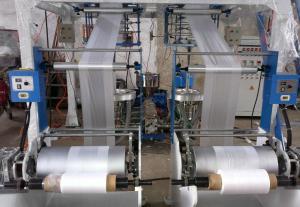

Polyethylene Blown Film Machine/Mini film blowing machine

2. Material : LDPE

3. Output: 80kg/h

4. Film Width:800~1200mm

Polyethylene Blown Film Machine

The machine is used to blowing PE film.

EX-40:

L:D=30:1

OUTPUT:35 KG/H

FILM WIDTH:200--400

EX-65:

L:D=30:1

OUTPUT:80KG/H

FILM WIDTH:800--1200

- Q: How does the oil filter usually be repaired and maintained?

- Then place it where it is not easy to damp and dry. As for the maintenance of oil filters, specific conditions should be analyzed and treated.

- Q: Where has the waste lubricating oil to come in, it is the oil filter of the finished oil

- At least there is no such machinery in our country. Refined oil is produced by processing crude oil. It can be divided into 6 categories: petroleum fuel, petroleum solvent and chemical raw material, lubricant, paraffin wax, petroleum asphalt and petroleum coke. Among them, the oil fuel production is the largest, accounting for about 90% of the total output; the most varieties of lubricants, and about 5% of output. All countries have developed product standards to meet the needs of production and use

- Q: How often is the filter element of the transformer oil vacuum oil filter changed?

- Usually a good filter can be cleaned and reused later until it is broken. Some are changed only once a year, and some half a year, according to the oil,

- Q: Under what conditions does the air pressure oil filter fail to clean oil?

- Oil is too dirty or used in an unsuitable oil filter. There will be filters that are not clean

- Q: Why should the centrifugal oil filter add brine and the proportion of brine?

- Centrifugal oil filter, filter oil plus brine, which is related to the design principle of the centrifugal oil filter.

- Q: Operation of centrifugal oil filter

- Check motor steering. Especially after the first start-up or the overhaul of the motor equipment. 1. start(1) start the separator, if the machine vibration abnormal, should stop immediately, check the drum assembly.(2) after the parts are normal, restart the separator. Due to the large inertia of the drum, the instantaneous load at the start of the motor will exceed the rated value, and the current will increase rapidly. When the separator reaches the rated speed, the current is stable and lower than the rated value of the motor. It takes about 5 minutes to start the whole process. When the speed is in accordance with the main technical parameters of the separator, it indicates that the separator has reached full speed.

- Q: Hydraulic press to buy automatic integration of good or alone to buy the right?

- Integrated oil filter sounds more advanced, in fact, we analyze its structure, it is known that an integral oil press is good, or separate good.

- Q: Advantages and disadvantages of pneumatic oil filter

- Vertical tank will be more than oil, you open the valve, drain oil ah. People say no bad oil, you believe ah?

- Q: Imported vacuum purifier, oil filter, why Parker is known as the world's first?

- Ask what the steel plant, not the preferred Parker Hannifin, the masses and not sand, as to design institute bigwigs fudge, a few. Who would like to pay a high price for something that other brands can't use?.

- Q: What's the difference between an oil filter and an oil filter?

- Filter oil filter oil filter is sometimes called, if you wanted a device, look at the oil filter, just want a simple small oil filter, we recommend that you can see the light oil filter on the market, or portable type oil filter.

Send your message to us

Polyethylene Blown Film Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords