Three to five layers co-extrusion film blowing machine set (IBC), extruder,Plastic blowing machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | nude packing or wooden case packing as your request |

| Delivery Detail: | 30 days after receipt 30%T/T as deposite |

Three to five layers co-extrusion film blowing machine set (IBC), extruder, blowing machine

This machine set is to satisfy the customer’s requirements of high quality, high output film blowing equipment.

It adopts the extruder with force feeding function, precision type ceramic heater, precision type double vents air ring, horizontal type rotary traction system, fully automatic surface friction type double cut double winders, computer concentrate control system.

Advanced technique and equipments, compare with kindred equipment, it has the advantages such as more compact structure, high output, better produce quality, less energy consume, easier operation.

It can be widely used into various kind of high transparence packing film manufacture and create the considerable economic benefit for you.

Fully automatic double cut double winders

Optional parts:

Auto loaderX3pcs

Chiller

Corona

Full automatic winder

Embossing roller

collecting material drop

Technical data:

Model | MD-3L50 | MD-3L55 | MD-3L65 |

Suitable Material | LDPE LLDPE EVA HDPE | ||

Max Film Width(mm) | 1200 | 1500 | 2000 |

Film Thickness(mm) | LD:0.015-0.15 | ||

Max Extrusion Output LD | 140kg/hr | 200kg/hr | 280kg/hr |

Extrusion unit | |||

Gear Box | 146/173/146 | 173/200/173 | 200×3 |

Screw Diameter(mm) | φ50/55/50 | φ55/65/55 | φ65/65/65 |

Screw L/D Ratio | 28:1 | ||

Screw’s Material | 38 CRMOALA | ||

Barrel’s Material | 38 CRMOALA | ||

Barrel’s Cooling Fan | 370W×2×3 | 370W×2×3 | 370×3×3 |

Thermo Control (zone) | 3×3 | 3×3 | 4×3 |

Driving Motor (kw) | 15/22/15 | 22/30/22 | 30/30/30 |

Extrusion Die | |||

Die Size (mm) | LD:φ250/300 | LD:φ350/400 | LD:φ500 |

Rotary Die Head (mm) | 360°Continue Rotary | ||

Screen Changer | Manual Mechanics Screen Changer | ||

Thermo Control (zone) | 3 | 4 | 4 |

Air Ring | 1 PCS | ||

Cooling Blower (kw) | 5.5 | 7.5 | 11 |

Take-UP Unit | |||

Roller Width (mm) | φ165×1300 | φ165×1600 | φ190×2100 |

Take-UP Motor (kw) | 1.5 | 1.5 | 2.2 |

Take-UP Speed(M/min) | 5-60 | 5-60 | 5-60 |

Winding Unit | |||

Type OF Winder | Surface Friction Double Winder | ||

Roller Width (mm) | 1300 | 1600 | 2100 |

Winding Motor | 16N.M | 1.5kw | 1.5kw |

Winding Speed(M/min) | 5-60 | 5-60 | 5-60 |

Voltage | 380V, 50HZ, 3PHASE | ||

Cover Dimensions (m) | 6.8×2.6×6.5 | 7.5×3.2×7.5 | 9×4.2×9 |

Three to five layers co-extrusion film blowing machine set (IBC), extruder, blowing machine

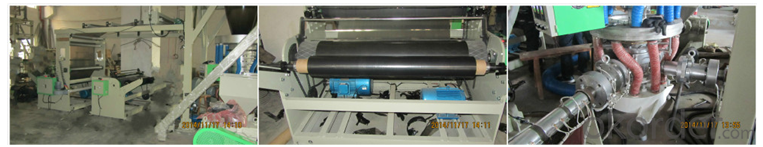

Machine at factory,double winder,simple type

Our other hot-sale machine(click the picture to know more information)

Company show

- Q: Dr. oil mill, bag filter, instructions for use

- Working principleThe vacuum oil filter is designed according to the different boiling points of water and oil. It consists of a vacuum heating tank, a fine filter, a condenser, a primary filter, a water tank, a vacuum pump, an oil drain pump and an electric cabinet.

- Q: Which filter is the best for peanut oil filter?

- It must be centrifugal and expensive. The plate and frame can only be replaced with filter cloth, but the plate and frame are troublesome, and he can not dephosphorization. Phosphorus is often eaten and is harmful to people's health. Http://www.zzlvyouji /4/%E6%A6%A8%E6%B2%B9%E8%AE%BE%E5%A4%87%E6%BB%A4%E6%B2%B9%E6%9C%BA.html you can see that it will help you know more about the oil filter

- Q: How to assemble and disassemble the vacuum pump for power generation oil filter?

- After the warranty period if you can point out the money and allow them to install, if they don't want to come, let them call instruction, could not provide service, customer service, customer service service are not even, such companies also want to do

- Q: Causes of heating in condensing tank of vacuum oil filter

- From which we can see, from the inside out after the vacuum flash tower is divided into two paths, one path through the filtered oil pump separated; the other way separated water and gas to the gas separation device (jar), and then through the condenser (usually air cooling or water cooling), after cooling, gas and water discharge.

- Q: Why should the centrifugal oil filter add brine and the proportion of brine?

- The principle of the centrifugal oil filter is to drive the internal cylinder of the oil filter at high speed through the rotation of the motor to produce a centrifuge, forcing the larger proportion of the sludge to be thrown and attached to the inner wall of the oil filter. Thus the effect of filtering oil is reached.

- Q: When peanut oil filter oil filter oil dregs particularly what is going on

- Peanut oil filter oil filter oil dregs more, the first is the oil material is dirty, second fried fry old, is fried.

- Q: What are the oil filters for? What are they used for?

- The lubricating system is filtered through the oil filter system to filter the impurities and moisture,

- Q: What are the main use of oil filters?

- Gas stations, oil producing enterprises, etc., as long as the used oil can be used

- Q: I am pressed sunflower oil, vacuum phase electric heating oil filter, oil filter to the end why there is a place

- In short, there is foam very normal, static for a while, there will be No.If the cooking oil is heated after foam, that phospholipids in oil more, you need to dephosphorization.

- Q: Which is more advantageous than a centrifugal oil filter and a vacuum oil filter?

- The first is to optimize the structure, centrifugal oil filter machine adopts the new centrifuge system is small, and thus the structural shape optimization of equipment can do better, smaller, less noise, the unit energy consumption decreased.

Send your message to us

Three to five layers co-extrusion film blowing machine set (IBC), extruder,Plastic blowing machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords