Three to five layers co-extrusion film blowing machine set (IBC), extruder, blowing machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | nude packing or wooden case packing as your request |

| Delivery Detail: | 30 days after receipt 30%T/T as deposite |

Three to five layers co-extrusion film blowing machine set (IBC), extruder, blowing machine

This machine set is to satisfy the customer’s requirements of high quality, high output film blowing equipment.

It adopts the extruder with force feeding function, precision type ceramic heater, precision type double vents air ring, horizontal type rotary traction system, fully automatic surface friction type double cut double winders, computer concentrate control system.

Advanced technique and equipments, compare with kindred equipment, it has the advantages such as more compact structure, high output, better produce quality, less energy consume, easier operation.

It can be widely used into various kind of high transparence packing film manufacture and create the considerable economic benefit for you.

Fully automatic double cut double winders

Optional parts:

Auto loaderX3pcs

Chiller

Corona

Full automatic winder

Embossing roller

collecting material drop

Technical data:

Model | MD-3L50 | MD-3L55 | MD-3L65 |

Suitable Material | LDPE LLDPE EVA HDPE | ||

Max Film Width(mm) | 1200 | 1500 | 2000 |

Film Thickness(mm) | LD:0.015-0.15 | ||

Max Extrusion Output LD | 140kg/hr | 200kg/hr | 280kg/hr |

Extrusion unit | |||

Gear Box | 146/173/146 | 173/200/173 | 200×3 |

Screw Diameter(mm) | φ50/55/50 | φ55/65/55 | φ65/65/65 |

Screw L/D Ratio | 28:1 | ||

Screw’s Material | 38 CRMOALA | ||

Barrel’s Material | 38 CRMOALA | ||

Barrel’s Cooling Fan | 370W×2×3 | 370W×2×3 | 370×3×3 |

Thermo Control (zone) | 3×3 | 3×3 | 4×3 |

Driving Motor (kw) | 15/22/15 | 22/30/22 | 30/30/30 |

Extrusion Die | |||

Die Size (mm) | LD:φ250/300 | LD:φ350/400 | LD:φ500 |

Rotary Die Head (mm) | 360°Continue Rotary | ||

Screen Changer | Manual Mechanics Screen Changer | ||

Thermo Control (zone) | 3 | 4 | 4 |

Air Ring | 1 PCS | ||

Cooling Blower (kw) | 5.5 | 7.5 | 11 |

Take-UP Unit | |||

Roller Width (mm) | φ165×1300 | φ165×1600 | φ190×2100 |

Take-UP Motor (kw) | 1.5 | 1.5 | 2.2 |

Take-UP Speed(M/min) | 5-60 | 5-60 | 5-60 |

Winding Unit | |||

Type OF Winder | Surface Friction Double Winder | ||

Roller Width (mm) | 1300 | 1600 | 2100 |

Winding Motor | 16N.M | 1.5kw | 1.5kw |

Winding Speed(M/min) | 5-60 | 5-60 | 5-60 |

Voltage | 380V, 50HZ, 3PHASE | ||

Cover Dimensions (m) | 6.8×2.6×6.5 | 7.5×3.2×7.5 | 9×4.2×9 |

Three to five layers co-extrusion film blowing machine set (IBC), extruder, blowing machine

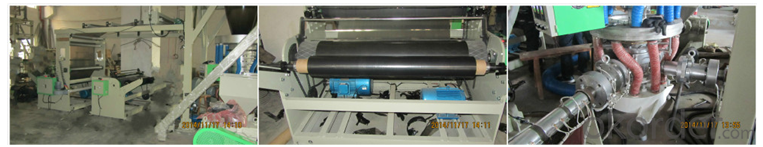

Machine at factory,double winder,simple type

Our other hot-sale machine(click the picture to know more information)

Company show

- Q: What is the reason for the fuel injection of the turbine vacuum pump?

- Vacuum pump exports of oil eventually derived from vacuum separation tank, the reasons are: 1, the treatment of oil is too bad, too much moisture in the oil, vacuum tank separation of water is too much

- Q: Where is the vacuum oil purifier repaired?

- Vacuum oil filter is not a big problem, generally vacuum filter oil machine leakage, welding, welding die.

- Q: What is the working principle of the vacuum oil filter?It's easy to understand

- In the filter to filter out large particles of impurities in oil, but can not filter out the compound emulsion regeneration and oxide molecular structure, often need to pay attention to clean the filter in the process of using, easily broken or blocked.

- Q: Peanut oil centrifugal filter and vacuum oil filter which is good?

- (with three different types of output) by the original 1800 speed and further improve the way to start, flexible start, let the oil filter to use more energy saving power with reduced half, do not cover slag, large caliber more convenient, centrifugal oil filter can be tiny impurities the crude oil inside, under the action of centrifugal force to make oil completely from the brightness, taste, health and safety environmental protection. For the use of more oil and oil increase efficiency.

- Q: The characteristics of plate and frame pressure oil filters? How often is the filter changed?

- The filter bed consists of multilayer filter plate and the filter frame, the filter media as paper or cloth lining the filter plate and the filter frame, with the pressure of the pressing device to filter plate and the filter frame to form a fixed filter chamber alone, tightly pressed between the filter plate and the filter frame of the paper or cloth filtration effect.

- Q: What's the difference between a purifier and an oil purifier? Or the purifier is the oil filter

- In addition to the impurities in the oil, the purifier can also separate the moisture in the oil. The oil filter is only a simple filtration of impurities.

- Q: What should be noticed when using an oil filter?

- Read the manual operation notices, avoiding all kinds of dangerous operations: for example, to avoid leakage, no grounding, fire and other operator skin water may result in electric shock behavior; and cannot speak not to direct contact with safety components, such as motor and pump rotor, bearing rotating part, centrifuge rotation can not be on hand hand deep oil filter machine.

- Q: My vacuum oil filter doesn't filter. Consult an expert

- Vacuum oil filter can not work properly, you should first think of is the direct dial phone manufacturers, the company let oil filter arranged professional and technical personnel on-site to solve, which is the least of the customer service service, but at least you as a consumer rights.

- Q: Filter turbine oil filter, filter Q oil?

- You filter out up to the transformer oil filtering requirements, in strict distinction between the situation, you alone or buy a good TY zjc filter for turbine oil, ZYA double stage vacuum oil filter machine transformer oil, separate filter better, to prevent oil mixed pollution

- Q: Has anyone filtered vegetable oil with a plate and oil filter?

- If it is to filter edible vegetable oil, the material, production conditions, the environment has many requirements, after all, involving food safety, must be all stainless steel material.Finally, the vegetable oil is filtered by plate and frame oil filter. The filter paper and filter paper must be made of pure cotton fiber, so as to reduce and eliminate chemical pollution.

Send your message to us

Three to five layers co-extrusion film blowing machine set (IBC), extruder, blowing machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords