Three And Five Layers Co-Extrusion Film Blowing Machine Set (IBC), Extruder, Blowing Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | nude packing or wooden case packing as your request |

| Delivery Detail: | 30 days after receipt 30%T/T as deposite |

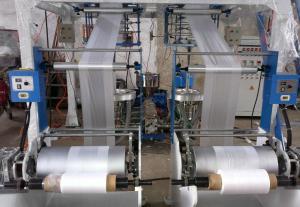

Three to five layers co-extrusion film blowing machine set (IBC), extruder, blowing machine

This machine set is to satisfy the customer’s requirements of high quality, high output film blowing equipment.

It adopts the extruder with force feeding function, precision type ceramic heater, precision type double vents air ring, horizontal type rotary traction system, fully automatic surface friction type double cut double winders, computer concentrate control system.

Advanced technique and equipments, compare with kindred equipment, it has the advantages such as more compact structure, high output, better produce quality, less energy consume, easier operation.

It can be widely used into various kind of high transparence packing film manufacture and create the considerable economic benefit for you.

Fully automatic double cut double winders

Optional parts:

Auto loaderX3pcs

Chiller

Corona

Full automatic winder

Embossing roller

collecting material drop

Technical data:

Model | MD-3L50 | MD-3L55 | MD-3L65 |

Suitable Material | LDPE LLDPE EVA HDPE | ||

Max Film Width(mm) | 1200 | 1500 | 2000 |

Film Thickness(mm) | LD:0.015-0.15 | ||

Max Extrusion Output LD | 140kg/hr | 200kg/hr | 280kg/hr |

Extrusion unit | |||

Gear Box | 146/173/146 | 173/200/173 | 200×3 |

Screw Diameter(mm) | φ50/55/50 | φ55/65/55 | φ65/65/65 |

Screw L/D Ratio | 28:1 | ||

Screw’s Material | 38 CRMOALA | ||

Barrel’s Material | 38 CRMOALA | ||

Barrel’s Cooling Fan | 370W×2×3 | 370W×2×3 | 370×3×3 |

Thermo Control (zone) | 3×3 | 3×3 | 4×3 |

Driving Motor (kw) | 15/22/15 | 22/30/22 | 30/30/30 |

Extrusion Die | |||

Die Size (mm) | LD:φ250/300 | LD:φ350/400 | LD:φ500 |

Rotary Die Head (mm) | 360°Continue Rotary | ||

Screen Changer | Manual Mechanics Screen Changer | ||

Thermo Control (zone) | 3 | 4 | 4 |

Air Ring | 1 PCS | ||

Cooling Blower (kw) | 5.5 | 7.5 | 11 |

Take-UP Unit | |||

Roller Width (mm) | φ165×1300 | φ165×1600 | φ190×2100 |

Take-UP Motor (kw) | 1.5 | 1.5 | 2.2 |

Take-UP Speed(M/min) | 5-60 | 5-60 | 5-60 |

Winding Unit | |||

Type OF Winder | Surface Friction Double Winder | ||

Roller Width (mm) | 1300 | 1600 | 2100 |

Winding Motor | 16N.M | 1.5kw | 1.5kw |

Winding Speed(M/min) | 5-60 | 5-60 | 5-60 |

Voltage | 380V, 50HZ, 3PHASE | ||

Cover Dimensions (m) | 6.8×2.6×6.5 | 7.5×3.2×7.5 | 9×4.2×9 |

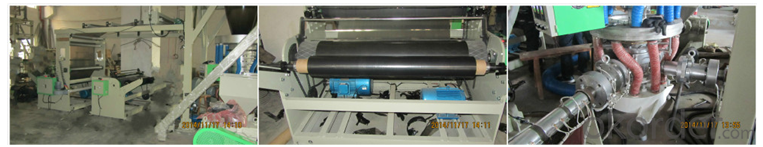

Three to five layers co-extrusion film blowing machine set (IBC), extruder, blowing machine

Machine at factory,double winder,simple type

Our other hot-sale machine(click the picture to know more information)

Company show

- Q: I would like to ask the following prawns, oil filters to do the sale, which customers should be running or units?

- Don't tell me can vacuum oil filter with high precision deimpurity ah, the wire net can be useful not pull, and now the electrostatic oil filter, high precision oil filter, membrane filtration, centrifugal oil filter, too much, which each have a lot of technology, too much,

- Q: Centrifugal oil filter and oil separator decanter which good (mainly oil quality)

- Filter to what extent, and then to select the oil filter, centrifugal filter oil filter impurities, oil and water separation effect can be

- Q: What is the difference between the high efficiency vacuum oil filter and the two-stage vacuum oil filter in transformer oil filter?

- The transformer cannot be evacuated. The two-stage vacuum oil filter is based on the single stage vacuum oil filter, with more roots pump and large pumping speed, which can quickly and efficiently remove water vapor in the oil

- Q: How much is the optimum temperature for cooking oil in a centrifugal oil filter?

- 70-80 degrees is the best filter temperature, and I hope to help you!

- Q: Where has the waste lubricating oil to come in, it is the oil filter of the finished oil

- Waste lubricating oil is used after the deterioration has been unable to use the oil, oil filter main machine is mainly pure physical filtration, filtration, filtration, removal of impurities of water gas, waste oil emulsion breaking, can recover after filtration DY lubricating oil vacuum oil filter function, cleanliness, moisture, gas content so, the acid value can be restored to the new oil standards, this time can be put into repeated use.

- Q: How often is the filter element of the transformer oil vacuum oil filter changed?

- How long is the filter element of the transformer oil vacuum filter? There is no definite time

- Q: Pneumatic oil filter is slow, isn't it too low?

- The vacuum oil filter can filter water, and can also filter impurities, in which the function of filtering impurities is achieved by strong magnetic adsorption and filter blocking,

- Q: What are the types of oil filters? Oil filter?

- The third generation vacuum oil filter uses filter core filter to remove water and some impurities, and the fourth generation purifier does not use filter core, filter screen, filter cloth and filter paper to completely remove water and impurities.

- Q: What kind of oil can the oil filter handle?

- 5, there is a distillation of diesel oil processing equipment, for the national introduction of diesel standards, from the beginning of the second half of 2016, diesel oil purification equipment becomes popular, but Dingneng launched in 2013 for the diesel processing equipment, and now the technology has matured, the nature of this device does not change the oil. The coalescence distillation method, high efficiency and good effect. Such as: common oil + turbine oil, insulating oil, lubricating oil and quenching oil, rolling oil, cold oilIn theory, all kinds of oil can be processed, but now the domestic oil filter technology is uneven, so some of the oil treatment has a certain degree of difficulty, it needs to be tailored according to the actual situation of the user.

- Q: How much is the equipment for the oil press?

- It is wrong that all the cases should be fitted with the same equipment.Should be configured according to different circumstances, such as: centrifugal oil filter can not filter cold oil.Therefore, in the cold press cooking oil, do not choose centrifugal oil filter, and hot pressed cooking oil, usually choose centrifugal oil filter.

Send your message to us

Three And Five Layers Co-Extrusion Film Blowing Machine Set (IBC), Extruder, Blowing Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords