Three And Five Layers Co-Extrusion Film Blowing Machine , Plastic Blowing Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | nude packing or wooden case packing as your request |

| Delivery Detail: | 30 days after receipt 30%T/T as deposite |

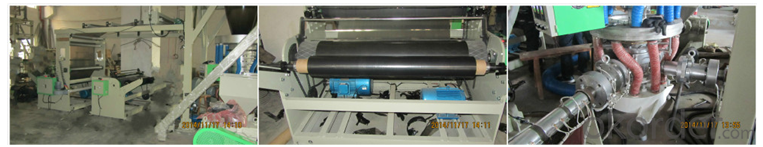

Three to five layers co-extrusion film blowing machine set (IBC), extruder, blowing machine

This machine set is to satisfy the customer’s requirements of high quality, high output film blowing equipment.

It adopts the extruder with force feeding function, precision type ceramic heater, precision type double vents air ring, horizontal type rotary traction system, fully automatic surface friction type double cut double winders, computer concentrate control system.

Advanced technique and equipments, compare with kindred equipment, it has the advantages such as more compact structure, high output, better produce quality, less energy consume, easier operation.

It can be widely used into various kind of high transparence packing film manufacture and create the considerable economic benefit for you.

Fully automatic double cut double winders

Optional parts:

Auto loaderX3pcs

Chiller

Corona

Full automatic winder

Embossing roller

collecting material drop

Technical data:

Model | MD-3L50 | MD-3L55 | MD-3L65 |

Suitable Material | LDPE LLDPE EVA HDPE | ||

Max Film Width(mm) | 1200 | 1500 | 2000 |

Film Thickness(mm) | LD:0.015-0.15 | ||

Max Extrusion Output LD | 140kg/hr | 200kg/hr | 280kg/hr |

Extrusion unit | |||

Gear Box | 146/173/146 | 173/200/173 | 200×3 |

Screw Diameter(mm) | φ50/55/50 | φ55/65/55 | φ65/65/65 |

Screw L/D Ratio | 28:1 | ||

Screw’s Material | 38 CRMOALA | ||

Barrel’s Material | 38 CRMOALA | ||

Barrel’s Cooling Fan | 370W×2×3 | 370W×2×3 | 370×3×3 |

Thermo Control (zone) | 3×3 | 3×3 | 4×3 |

Driving Motor (kw) | 15/22/15 | 22/30/22 | 30/30/30 |

Extrusion Die | |||

Die Size (mm) | LD:φ250/300 | LD:φ350/400 | LD:φ500 |

Rotary Die Head (mm) | 360°Continue Rotary | ||

Screen Changer | Manual Mechanics Screen Changer | ||

Thermo Control (zone) | 3 | 4 | 4 |

Air Ring | 1 PCS | ||

Cooling Blower (kw) | 5.5 | 7.5 | 11 |

Take-UP Unit | |||

Roller Width (mm) | φ165×1300 | φ165×1600 | φ190×2100 |

Take-UP Motor (kw) | 1.5 | 1.5 | 2.2 |

Take-UP Speed(M/min) | 5-60 | 5-60 | 5-60 |

Winding Unit | |||

Type OF Winder | Surface Friction Double Winder | ||

Roller Width (mm) | 1300 | 1600 | 2100 |

Winding Motor | 16N.M | 1.5kw | 1.5kw |

Winding Speed(M/min) | 5-60 | 5-60 | 5-60 |

Voltage | 380V, 50HZ, 3PHASE | ||

Cover Dimensions (m) | 6.8×2.6×6.5 | 7.5×3.2×7.5 | 9×4.2×9 |

Three to five layers co-extrusion film blowing machine set (IBC), extruder, blowing machine

Machine at factory,double winder,simple type

Our other hot-sale machine(click the picture to know more information)

Company show

- Q: How to solve the oil press foam?

- The centrifugal oil filter pours in the oil and then turns on the machine. It can be filtered for 35 minutes

- Q: Peanut oil centrifugal filter and vacuum oil filter which is good?

- (with three different types of output) by the original 1800 speed and further improve the way to start, flexible start, let the oil filter to use more energy saving power with reduced half, do not cover slag, large caliber more convenient, centrifugal oil filter can be tiny impurities the crude oil inside, under the action of centrifugal force to make oil completely from the brightness, taste, health and safety environmental protection. For the use of more oil and oil increase efficiency.

- Q: How often do you change the oil filter when the turbine is in oil?

- Hello In fact, these things is not a fixed pattern, because it is with a barrel of oil, from all above and below, and you are a group of oil? This is what we do on the machine. Add a pressure controller to the pressure filter and automatically remind you that you should change the filter paper by proper debugging

- Q: Operation of centrifugal oil filter

- 3. stopA. turn off the heater and switch the valve to allow the sump oil to enter the sump tank through the recirculation system net.B. cut off the power supply. If the separator is to stop as soon as possible, the brake (brake) can be used after the speed drops to 1000 rpm. To avoid excessive wear of the friction disc, the drum speed is more than 1000 revolutions per minute, as much as possible without the use of the brake.C. the drum must be cleaned every time the work is done;Caution: do not loosen any fasteners on the machine until the drum has stopped completely. Points for attention in the use of edible oil filter

- Q: I bought the yigayi press... To peanut oil processing. Others froth overflow, can precipitate it. Oil, foam heat. But it was cold, processed oil directly frozen. They call headquarters, they let me use salt and alkali and alum. In accordance with the proportion of with boiling water stir, add the oil mix, I give people processing oil. So how could I home on the edge of this ah, what a good way?

- Although it looks clear, there are still impuritiesWhen you stir fry, add water evenly,

- Q: Why does the oil filter run out of vacuum? How can we solve it?

- The cause of the accident in the oil level is too high) vacuum separator solution) open the equipment town valve, in order to reduce the level of vacuum separator in Chongqing tonre oil company to remind all the new and old customers, if you want to save the trouble, the best is in the purchase of equipment, requires manufacturers, provided with vacuum oil filter automatic bubble elimination device., this device can effectively prevent the vacuum injection, so as to protect the safety of the vacuum pump, prolonging the service life of the vacuum pump, to ensure safe and reliable operation of the vacuum oil filter, and also has the advantages of simple operation, reliable operation, easy maintenance, so that the oil filter efficiency will be higher. The above is the oil filter operation in the common fuel injection phenomenon, troubleshooting methods, hoping to filter oil customers in all industries to bring convenience.

- Q: How to deal with the overload indication of two-stage vacuum oil filter

- What is overload, pressure overload, or temperature overload, or voltage overload, you don't make it clear?

- Q: Disadvantages of centrifugal oil filter

- Hello, centrifugal oil filters are produced by high speed motors to generate centrifugal force

- Q: Double barrel automatic electric heating centrifugal oil filter and oil separation automatic horizontal centrifugal oil filter which is better than

- Heating centrifugal oil filter is generally filtered, emulsified, that is, more water. Oil centrifugal oil filter oil filter more impurities

- Q: Is the pressure type oil filter better than the vacuum oil filter?

- The pressure type oil filter doesn't have a vacuum oil filter

Send your message to us

Three And Five Layers Co-Extrusion Film Blowing Machine , Plastic Blowing Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords