Waterseal Mastic RoHS Compliant Resistant to Corrosion

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 500000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of KC86 Tape

• KC 86 is a self-amalgamating mastic tape used for moisture sealing on all types of telecommunications and solid dielectric power cable splices and connections.

• It is a tacky, temperature stable mastic with excellent conformability and adhesion to metal and all types of cable insulations and jackets.

• It is put up on a white release coat separator in roll form without any core.

• Once applied, KC 86 mastic should be overwrapped with a vinyl or rubber tape which will encapsulate it and, throug centripetal force, make it into every crevice and indentation in a cable jacket thereby giving a superior moisture seal in a splice or aroun any connection.

• The tape is also RoHS compliant, resistant to corrosion, chemicals and salt water and has no adverse effect on cable insulations.

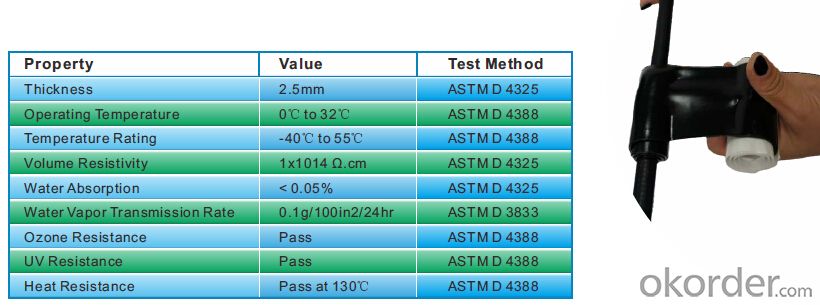

• Its 2.5mm thickness facilitates rapid protection build-up.

• Use in conjunction with KC 63 premium vinyl electrical tape for optimal performance.

Dimensions of KC86 Tape

2.5” x .1” x 23.6”

63mm(width) x 2.5mm(Thickness) x 0.6m(length)

Consult us for other sizes

Specifications of KC86 Tape

Applications of KC86 Tape

• Moisture seal and insulation in power cable through 600 volts

• Moisture seal and insulation of telecommunication cable connections in base stations, antennas and aerial feeders

• Other moisture sealing applications

FAQ

1.Before placing order, can we make sample firstly?

Sample can be arranged to send to you to test before placing order.

Sometimes sample is free ,sometimes sample charge should be included if more than 3 pcs with material .

But we are afraid freight charge will be paid by yourself.

Certainly, we will adjust additional sample and freight charges into your bulk order.

2.How can I get your sample?

Of course, we can send you some samples. Most samples are free, but sometimes we will take small sample fees.

Maybe you also send us your DHL or EMS/UPS/TNT etc account ,so you can pay for air freight to your carrier company directly.

3.Whether we can print our logo or need our color or size or not?

Yes, because we have our own factory and R&D team, so we can make products as your demands.

We can print your logo, we also can make as your size and print it as your color.

4.How many kinds of payment terms you can accept?

About payment terms, we would like 100%TT if less than $1000.00

Usually for bulk order , would like can be paid pay 30%- 50% advanced payment and the rest should be paid before dispatch.

We hope this information will be helpful to you, if you have any question, please feel free to contact us, we are always at your service.

- Q: What is the car waterproof sticker material?

- C. metal technology and other: metal technology refers to the aluminum plate and other metal plate through the machine to suppress the concavity and convex surface, and then made of metal paint color, and finally after grinding, drawing and other production of the car stickers (car standard); Area can not be too large, can only be used for a small range of iconic car stickers.

- Q: What is PE waterproof cloth and PVC tarpaulin

- The characteristics and performance index of waterproof cloth products 1. Tensile strength index: warp strength ≥ 2100N / 5CM, zonal strength ≥ 1600N / 5CM; 2. No leakage of water, water pressure ≥ 2000MM water column; 3. Low temperature, cold temperature -20 ℃; 4 Can be mildew, mildew experiment for the first level. Product Usage 1. Can be used car, train, ship cargo tarpaulin; 2. It can be used for the open storage of the harbor airport at the station terminal harbor; 3. Can be set up temporary granary and a variety of crops covered with open-air; 4. Can be used for construction site power construction site and other sites to build temporary shed, temporary warehouse materials; 5. Can be processed camping with tents and various machinery and equipment outside the jacket.

- Q: How to ensure the waterproof quality of the underground shear wall (retaining wall)?

- 3, according to the hydrogeological conditions and outdoor environment type to take the appropriate level of waterproof concrete.

- Q: What decoration materials, light and water, and the wall, the perfect combination of glass

- Third, the mouth of the mouth, put pressure glue gun Cut the hose tube, fitted with a pointed nozzle, and then according to the size of the gap will be cut by 45 degrees angle. Install the glue gun.

- Q: Waterproof mortar expensive or dry mortar expensive

- Cationic neoprene latex is a polymer modified polymer anti-corrosion system. By the introduction of imported epoxy resin modified latex by adding the domestic neoprene emulsion and polyacrylate, synthetic rubber, various emulsifiers, modified latex and other components of the polymer latex.

- Q: What material waterproofing can be mixed with cement sand

- Construction can be made with the waterproofing agent and cement made of waterproof mortar. The ratio of cement to sand is 2: 3, and the amount of waterproofing agent is 1% of the cement.

- Q: Oriental rain rain waterproof how to

- 1, the East Yuhong waterproof coating quality assurance In the national waterproof products and technology market, rain rain waterproof material is unique, is the product of long-term demand for professional waterproof brand, long-term dominate in the waterproof market.

- Q: Nanning building waterproof material market where

- This depends on what you need packaging materials, and if it is some packaging rope or paper or process raw materials and other different materials to find a different place, generally sold outside the packaging is more like Nanning near the train station Or the trading market,

- Q: Self-built concrete house finished three years after the use of large-scale housing wall leakage how to do?

- Third, from the indoor water leakage area for waterproof maintenance.

- Q: How does the waterproofing membrane work?

- 4, rolling the membrane: the first turn up the end of 1m long, with a long torch melting the bottom of the hot melt adhesive, the rapid paste fixed on the grassroots, and then re-harvest the rest of the volume. The gunmen stood on the paved webs, aligned with the corners of the rolls and the surface of the base layer with the flame of the long gun, and slowly rolled the edges by melting the hot melt. The web is pasted on the base;

Send your message to us

Waterseal Mastic RoHS Compliant Resistant to Corrosion

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 500000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords