Exterior Wall Transparent Waterproof Glue

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Exterior Wall Transparent Waterproof Glue Description:

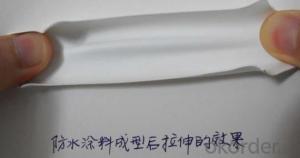

Exterior wall transparent waterproof glue adopts special polymer copolymer as basic material, through a variety of modified additives into a new type of waterproof coating glue (transparent). The product has a membranous, flexibility, abrasion resistance, permeability and excellent weatherability.It can be directly besmear brushs metope ceramic tile, stone, cement concrete base, peeling, pulverization, prevent cement base, effectively prevent the phenomenon of water seepage of base material, with long service life, in order to enhance the durability of metope provide reliable guarantee.It is a kind of water-based environmentally friendly product.

2.Main Features of Exterior Wall Transparent Waterproof Glue:

•Heat resistance, uv resistance, ozone resistance, acid and alkali resistance, weather resistance with

a wide range

•Coating has good film-forming property, strong adhesive relay

•Noncombustible, non-toxic, tasteless, no pollution

•Cold construction, safe operation, construction for convenient,low price.

3.Exterior Wall Transparent Waterproof Glue Specification:

| Number | Test Item | Index | ||

| 1. | Solid content (%) | >55 | ||

| 2. | Elongation rate(%) | ≤250 | ||

| 3. | Tensile strength (MPa) | >20 | ||

| 4. | Scrub resistance(Time) | 1500 |

4.Exterior Wall Transparent Waterproof Glue Images:

- Q: How to do waterproof bathroom, construction process is what

- 3, shop protective layer. In order to prevent the subsequent construction damage to the waterproof layer, the need to cover the surface of the waterproof coating protective layer. Protective layer to completely cover the waterproof layer, no missing, with the grass-roots combination of solid, no cracks, no bubbles, no shedding phenomenon.

- Q: What is PE waterproof cloth and PVC tarpaulin

- PE tarpaulin, anti-aging, anti-aging, anti-corrosion, light, easy to fold, relative to the PVC tarpaulin, PE tarpaulin cheaper price for the freight yard, the service life will be shorter.

- Q: How to ensure the waterproof quality of the underground shear wall (retaining wall)?

- 5, in strict accordance with the underground waterproofing procedures for concrete construction and construction of waterproofing membrane, a reasonable set of settlement and construction joints, to reduce the structure of the crack; for the structure of stubble, settlement joints, construction joints to take the necessary waterproof measures (additional Waterproof layer or set the water-stop plate, water strips, etc.). 6, to strengthen the hidden acceptance, the good quality off.

- Q: What decoration materials, light and water, and the wall, the perfect combination of glass

- Third, the mouth of the mouth, put pressure glue gun Cut the hose tube, fitted with a pointed nozzle, and then according to the size of the gap will be cut by 45 degrees angle. Install the glue gun.

- Q: Can acrylic materials be perforated? How to do waterproof after punching?

- Or in the back with glass adhesive paste anti-corrosion nine PCT board (if the hole is flat, Anti-corrosion nine PCT is to remove the other side of the paste surface with asphalt anti-corrosion paint brush)

- Q: Js waterproof coating without powder can brushing

- 5. Coating maintenance: JS cement-based waterproof emulsion coating construction after 24 hours after the end with a damp cloth to cover the coating or spray water to maintain the coating, usually 2-3 days; air humidity, poor ventilation of the local dry The time period may be longer, and vice versa; 6. Check the construction of JS waterproof coating (closed water test): bathroom, pool and other parts in the JS cement-based waterproof emulsion waterproof layer after dry (at least 24 hours in summer, at least 48 hours in winter) stored water for 48 hours to see the water Construction is not qualified. Light wall must do the water test. JS waterproof coating See the amount of: under normal circumstances, the amount of about 0.6-1kg / ㎡, the actual amount from the use, the use of parts, rough surface roughness, environmental factors such as the decision.

- Q: Roof leakage, what materials do the best waterproof

- The Second, if the roof is only the original did not do waterproof, only need to remove the leaky parts of 2 ~ 3cm deep after cleaning, you use asphalt irrigation, and now there is finished asphalt coating, such as sunny day when the treatment will basically not Leaked out. If there is a waterproof layer is too much trouble, to be around a range of waterproof tick, re-do waterproof, do when the attention and the original waterproof junction to do reinforcement layer. There are many ways to deal with leak detection, or to find some professional leak-proof companies to deal with this problem.

- Q: What should you pay attention to before the construction of the basement waterproofing membrane?

- 2, the mold of the nail set: in accordance with the pre-scheduled area along the painted bottom line nail with polyethylene film wrapped wood mold. Mold to be flat, with the basic nail implementation, to prevent leakage material.

- Q: What are the key points and contents of the quality control of waterproof material?

- 2, ordinary two-component polyurethane: A material is similar to the appearance of edible oil translucent yellowish curing agent from polyether and isocyanic acid by polycondensation of polyurethane prepolymer (about 20,000 yuan / t), B material For the plasticizer, coagulant, fillers and other components of the black liquid (about 3900 yuan / t), after mixing the polyurethane coating is also black. But also because of A, B material of the huge spread so often the following two kinds of fraud: ① with a very cheap black oil (priced at only about 1,200 yuan / t), diluted with xylene after thin coating twice. Cold oil is not easy to dry after the coating, after each coating must be drying a few days, in the winter with roasted, and then do not sprinkle dry powder cement, so a long time paint are dry. ② is often used to expand the proportion of A, B components such as 1: 4-6 (usually 1: 2), but also in the polyurethane mixing process by adding cement powder as a filler, if the stirring is not added xylene diluted Agents and other methods of fraud.

- Q: Rigid (concrete) waterproof roofing shop SBS coil can brush a layer of waterproof paint before?

- First, rigid (concrete) waterproof roofing SBS membrane should not be painted before the coating of any waterproof coating, otherwise it will damage the bonding strength of the coil and the grassroots.

Send your message to us

Exterior Wall Transparent Waterproof Glue

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords