Polyvinyl Chloride (PVC) Plastic Waterproofing Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

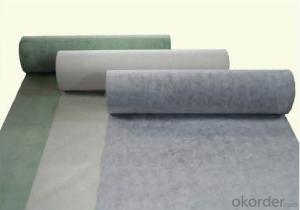

1. Introduction of PVC Waterproofing Membrane

Polyvinyl chloride the pvc waterproofing plastic membrane is a kind of excellent performance of polymer waterproof material,PVC resin as the main raw material,add all kinds of special additive and anti-aging composition,the use of advanced equipment and advanced technology extrusion rolling is made.The product has the tensile strength and elongation high shrinkage of small,low temperature soft good,long life and other advantages, the products wide 1.2m to 3.0m, the thickness of 0.8-2.0 mm(special specifications can be customized),stable performance,reliable quality,construction is convenient.

2. Specification of PVC Waterproofing Membrane

Length | 20m/roll or customized |

Width | 2.05m |

Thickness | 1.2mm; 1.5mm; 2.0mm |

Type | Homogeneous, Reinforced, Fabric back |

If Exposed | Exposed and Non-exposed |

Color | White, Grey or customized |

3. Features of PVC Waterproofing Membrane

1) Excellent aging resistance. Service life of roofing material is over 20 years;

service life of underground material is over 50 years.

2) Root resistant penetration, specially used on planting roof.

3) Welding installation. Joints are solid and environment friendly, no pollution.

4) High tensile strength, good elongation and dimensional stability.

5) Good plasticity, easy and suitable for details installation.

6) Fireproof. Fire extinguished out of the ignition resource.

7) Surface is smooth, no fading and dirty resistant.

4. Applications of PVC Waterproofing Membrane

1) All kinds of roofs, such as steel structure roof, planted roof etc.

2) Underground engineering, such as building basement, subways, tunnels, air raid shelter, etc.

3) Other projects like artificial lake, dam, water reservoir, grain storehouse, etc.

5. FAQ of PVC Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Are waterproofing membranes suitable for underground parking garages?

- Yes, waterproofing membranes are suitable for underground parking garages. They provide an effective barrier against water infiltration, preventing damage to the structure and protecting against potential leaks and moisture-related issues. Waterproofing membranes are designed to withstand the high water pressure typically associated with underground environments, making them an ideal solution for ensuring the longevity and durability of underground parking garages.

- Q: Is a waterproofing membrane resistant to hydrocarbons or oil spills?

- Yes, a waterproofing membrane is generally resistant to hydrocarbons or oil spills.

- Q: Are waterproofing membranes suitable for historical buildings?

- Under certain circumstances, historical buildings can benefit from the use of waterproofing membranes. These membranes are specifically designed to safeguard structures against water damage, which is especially important for historical buildings that may have aged and porous materials. However, the suitability of waterproofing membranes for historical buildings relies on a variety of factors. First and foremost, it is vital to take into account the unique requirements and characteristics of the historical building in question. Each building possesses distinct materials and features, and the impact of waterproofing on these elements must be thoroughly assessed. Some older structures may possess delicate architectural elements or materials that could be adversely influenced by the application of waterproofing membranes. In such instances, alternative methods that are less intrusive or damaging may be more appropriate. Secondly, it is essential to seek guidance from conservation experts or professionals who specialize in the preservation of historical buildings. These experts can evaluate the specific needs of the building and offer advice on the most suitable waterproofing techniques. They can also ensure that any interventions are executed in a manner that respects the historical integrity and authenticity of the structure. Lastly, it is crucial to consider the long-term consequences of waterproofing membranes on historical buildings. While these membranes can effectively protect against water damage, they may also compromise the natural breathability of the building, potentially leading to moisture accumulation and further deterioration. Therefore, it is imperative to carefully balance the benefits of waterproofing with the potential risks and long-term effects. In conclusion, while waterproofing membranes can be appropriate for historical buildings, caution should be exercised when applying them. A thorough assessment of the building's specific requirements, consultation with preservation experts, and consideration of long-term implications are essential in determining the suitability of waterproofing membranes for historical structures.

- Q: Can a waterproofing membrane be used on concrete block walls?

- Yes, a waterproofing membrane can be used on concrete block walls. It helps to prevent water penetration and protect the walls from moisture damage.

- Q: Does a waterproofing membrane affect the appearance or finish of a surface?

- Yes, a waterproofing membrane can affect the appearance or finish of a surface.

- Q: Are waterproofing membranes suitable for below-grade applications?

- Yes, waterproofing membranes are suitable for below-grade applications. These membranes are specifically designed to prevent water infiltration into basements, foundations, and other below-ground structures. They provide a protective barrier against groundwater, ensuring the integrity and longevity of the structure.

- Q: Can waterproofing membranes be used on stormwater management systems?

- Yes, waterproofing membranes can be used on stormwater management systems. These membranes provide a protective barrier that prevents water from infiltrating into the system, ensuring efficient and reliable stormwater management.

- Q: How does a waterproofing membrane prevent water infiltration?

- A waterproofing membrane prevents water infiltration by creating a physical barrier that is impermeable to water. This membrane is typically applied to surfaces such as roofs, foundations, or walls, and it effectively seals off any potential entry points for water. It acts as a protective layer, preventing water from seeping through and causing damage to the underlying structure.

- Q: Can a waterproofing membrane be used in foundations?

- Yes, a waterproofing membrane can be used in foundations. In fact, it is often recommended to install a waterproofing membrane in foundations to prevent water infiltration and potential damage to the structure. The membrane is typically applied to the exterior walls of the foundation and acts as a barrier against water penetration. It helps to keep the foundation dry and protects it from hydrostatic pressure, which can cause cracks and leaks. Additionally, a waterproofing membrane can also prevent moisture buildup, mold growth, and other issues related to water damage. Overall, using a waterproofing membrane in foundations is an effective and reliable method to ensure the long-term durability and stability of a building.

- Q: Asphalt waterproofing membrane and polymer waterproofing membrane

- It is a kind of self-adhesive polymer with self-adhesive function, such as butyl rubber and anti-sticking layer, which can be compounded with a certain thickness of the modified asphalt waterproofing membrane. Modified asphalt waterproofing membrane.

Send your message to us

Polyvinyl Chloride (PVC) Plastic Waterproofing Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords