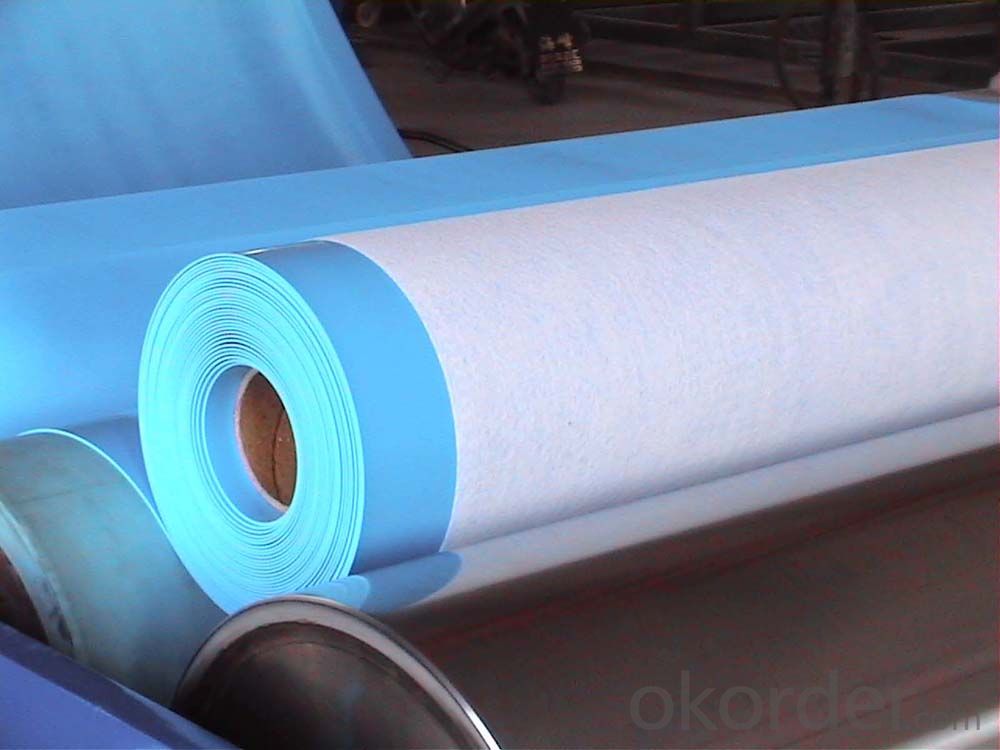

Polyvinyl Chloride (PVC) waterproofing membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Introduction of Polyvinyl Chloride (PVC) waterproofing membrane:

Polyvinyl Chloride (PVC) waterproofing membrane is a new polymer waterproof membrane which is made from polyvinyl chloride resin, and mixed with plasticizer,filler, antioxygen, ultraviolet absorber and other auxiliaries. DHK-8100 adopts automatic mixing of raw material, double-screw extruder and delicate three-roller calender equipment in the PVC membrane production. DHKchem PVC waterproof membrane features dimensional stability and high tensile strength, being a best choice for many civil and industrial project.

2.Physical data of Polyvinyl Chloride (PVC) waterproofing membrane:

No | Item | I | II | |

1 | Tensile strength/ Mpa | 8.0 | 12.0 | |

2 | Fracture elongation / % ≥ | 200 | 250 | |

3 | Heating flexibility / % ≤ | 3.0 | 2.0 | |

4 | Cold bending | -20°C No leaking | -25°C No leaking | |

5 | Water impermeability | Water impermeable | ||

6 | Binding property with cutting (N/mm) | 3.0/ breaking membrane | ||

7 | Hot air ageing | Appearance | No craze, no bubble, no cohering, hole | |

Tension strength % | ±25 | ±20 | ||

Fracture elongation changing rate | ||||

Cold bending % | -15°C No leaking | -20°C No leaking | ||

8 | Chemistry corrosion resistance | Tension strength % | ±25 | ±20 |

Fracture elongation changing rate | ||||

Cold bending % | -15°C No leaking | -20°C No leaking | ||

9 | Phytotrons accelerating ageing | Tension strength % | ±25 | ±20 |

Fracture elongation changing rate | ||||

Cold bending % | -15°C No leaking | -20°C No leaking | ||

10 | Note: no considering phytotrons accelerating ageing. | |||

3.Chatacteristics of Polyvinyl Chloride (PVC) waterproofing membrane:

Excellent performance in aging resistance, service life of 20 years for exposed use, and 50 years for non-exposed application.

Easy installation and hot-air welding seam, environmental friendly.

High tension, perfect elongation, perfect heating resistance.

Excellent jointing, it can be fused with base as a whole after heating jointing.

High permeability, chilling material and moisture can be expelled easily.

High UV resistance , corrosion resistance and erosion resistance.

High cold flexibility (-20°C).

Surface can reflect UV. The temperature on the surface is low due to little absorbing heat.

4.Application of Polyvinyl Chloride (PVC) waterproofing membrane:

Colorful polymer PVC waterproof membrane can variously be used on the roof of building, underground building, tunnel, dam, pool, sewage treatment works, and garbage disposal facilities. It also can be suitable to any requirement of all kinds of technological practice & different grade of roof waterproof and underground constructions waterproof.

- Q: Can a waterproofing membrane be used for sealing pipe penetrations?

- Sealing pipe penetrations can be achieved with the use of a waterproofing membrane. These membranes are specifically designed to form a barrier against water intrusion and can effectively seal different types of penetrations, including pipes. In construction projects, they are widely utilized to prevent water leaks and potential damage. By applying the waterproofing membrane around the pipe penetration, a watertight seal is created, preventing the entry or escape of water through the opening. This action helps maintain the building envelope's integrity and safeguards against potential water-related problems like leaks, mold growth, and structural damage. Moreover, waterproofing membranes often possess flexibility, enabling them to adapt to the shape and size of the pipe penetration, ensuring a secure and long-lasting seal.

- Q: Can a waterproofing membrane be used on precast plastic surfaces?

- Yes, a waterproofing membrane can be used on precast plastic surfaces. Waterproofing membranes are designed to create a barrier against moisture and can be applied to a variety of surfaces, including concrete, metal, and plastic. When properly installed, a waterproofing membrane can provide protection against water infiltration, ensuring the longevity and durability of the precast plastic surface. It is important to choose a waterproofing membrane that is compatible with plastic and follow the manufacturer's instructions for application to ensure proper adhesion and effectiveness.

- Q: Can a waterproofing membrane be used on tunnels with communication systems?

- Indeed, tunnels with communication systems can utilize a waterproofing membrane. It is strongly advised to shield delicate communication equipment and wiring from water-induced harm. A waterproofing membrane is specifically engineered to establish a protective barrier against water infiltration, thus averting leaks and seepage. By implementing a waterproofing membrane on the walls and floors of the tunnel, the communication systems can be shielded against possible water-related complications, including corrosion, short circuits, and disruption of signals. It is crucial to select a waterproofing system that aligns with the precise needs and prerequisites of the communication systems within the tunnel to guarantee optimum protection and functionality.

- Q: Are there any specific maintenance requirements for a waterproofing membrane?

- Yes, there are specific maintenance requirements for a waterproofing membrane. Regular inspections should be conducted to check for any signs of damage or deterioration, such as cracks or leaks. Any debris or standing water should be promptly removed to prevent potential damage. Additionally, it is important to follow the manufacturer's guidelines for cleaning and maintenance, which may include periodic cleaning with mild detergents and avoiding the use of harsh chemicals or abrasive cleaning tools.

- Q: Are waterproofing membranes suitable for crawl spaces?

- Yes, waterproofing membranes are suitable for crawl spaces. Crawl spaces are often prone to moisture and water intrusion due to their location and lack of ventilation. Waterproofing membranes provide an effective solution to prevent water damage and moisture-related problems in crawl spaces. These membranes are designed to create a barrier against water and moisture, preventing them from seeping into the crawl space and causing issues such as mold growth, rotting, and structural damage. Additionally, waterproofing membranes can also help to improve indoor air quality by reducing the levels of humidity in the crawl space. Overall, using waterproofing membranes in crawl spaces is highly recommended to ensure a dry, clean, and healthy environment.

- Q: Are there any specific considerations for installing a waterproofing membrane in high-traffic areas?

- Yes, there are several specific considerations when installing a waterproofing membrane in high-traffic areas. Firstly, the durability and strength of the membrane should be a top priority. High-traffic areas are subject to constant wear and tear from foot traffic, heavy equipment, and other activities. Therefore, the membrane should be able to withstand the load and pressure without getting damaged or compromised. Secondly, the slip resistance of the waterproofing membrane is crucial in high-traffic areas to prevent accidents and ensure safety. The surface of the membrane should provide sufficient grip to minimize the risk of slips and falls, especially in wet conditions. Additionally, the installation process should be carefully planned and executed in high-traffic areas. It is essential to minimize disruptions and inconveniences to the people using the area. This may involve scheduling the installation during off-peak hours or implementing temporary alternative pathways to ensure smooth traffic flow. Furthermore, the choice of materials is important in high-traffic areas. The waterproofing membrane should be resistant to chemicals, oils, and other substances that may be commonly found in such areas. This will help to prolong the lifespan of the membrane and maintain its functionality over time. Lastly, regular maintenance and inspection are crucial for long-term performance in high-traffic areas. The membrane should be regularly checked for any signs of damage or deterioration, and necessary repairs or replacements should be promptly carried out to ensure the continued effectiveness of the waterproofing system. In conclusion, installing a waterproofing membrane in high-traffic areas requires careful consideration of durability, slip resistance, installation process, material choice, and maintenance. By addressing these specific considerations, a waterproofing membrane can effectively protect the underlying structure while accommodating the demands of heavy foot traffic.

- Q: How does a waterproofing membrane handle exposure to high temperatures?

- The ability of a waterproofing membrane to withstand high temperatures relies on its composition and quality. These membranes are typically made from durable materials like bitumen, EPDM, or PVC, which have high melting points and can resist heat. These materials are carefully selected to ensure that the membrane remains intact and effective even when exposed to elevated temperatures. The resistance of high-quality waterproofing membranes to heat is enhanced through the use of additives and fillers during manufacturing. These additives help the membrane maintain its integrity, preventing it from softening, melting, or becoming brittle under high temperature conditions. Additionally, the successful installation of the waterproofing membrane is crucial to its ability to handle high temperatures. Proper installation techniques, such as ensuring adequate adhesion and seam sealing, are essential for maintaining the membrane's effectiveness and preventing any potential damage caused by heat exposure. To summarize, waterproofing membranes are specifically engineered to withstand high temperatures. Their composition, quality, and installation techniques all contribute to their ability to resist heat without deteriorating or losing their waterproofing properties.

- Q: Can a waterproofing membrane be used on precast copper surfaces?

- Yes, a waterproofing membrane can be used on precast copper surfaces. The membrane will create a barrier that prevents water penetration, ensuring the durability and longevity of the copper surface.

- Q: Can a waterproofing membrane be used in agricultural structures?

- In agricultural structures, like barns, greenhouses, and storage facilities, it is possible to utilize a waterproofing membrane. These structures often necessitate protection against moisture and water harm. A waterproofing membrane is a robust and flexible substance that can be applied to diverse surfaces such as roofs, walls, and floors to obstruct water infiltration. It functions as a barrier, stopping water from penetrating the structure and causing destruction to the building materials, equipment, and stored crops. Moreover, a waterproofing membrane can also assist in regulating the temperature and humidity levels within the agricultural structure, generating a more controlled and ideal environment for crops, livestock, and equipment. In summary, the utilization of a waterproofing membrane in agricultural structures can guarantee the durability and functionality of the building while safeguarding the valuable assets inside.

- Q: Can a waterproofing membrane be used in stadiums or sports complexes?

- Stadiums and sports complexes can indeed benefit from the use of waterproofing membranes. It is highly advisable to employ waterproofing solutions in these types of structures to safeguard them against water damage and leaks. The purpose of a waterproofing membrane is to serve as a barrier, preventing water from infiltrating the concrete or other construction materials employed in the stadium or sports complex. This is especially crucial in regions where heavy rainfall or high humidity levels are prevalent. Implementation of a waterproofing membrane on the roofs, walls, and foundations of these edifices helps guarantee their longevity and structural integrity, while also offering a comfortable and secure environment for athletes and spectators alike. Waterproofing membranes are specifically designed to endure the pressures and movements associated with the building, making them an optimal choice for stadiums and sports complexes. Additionally, contemporary waterproofing membranes come in diverse forms, including liquid-applied or sheet membranes. This allows for flexibility in application and compatibility with various construction materials.

Send your message to us

Polyvinyl Chloride (PVC) waterproofing membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords