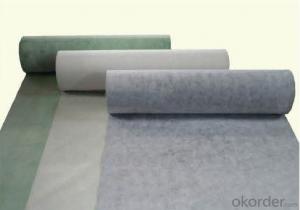

Polyvinyl Chloride (PVC) Waterproofing Membrane with UV Resistance

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

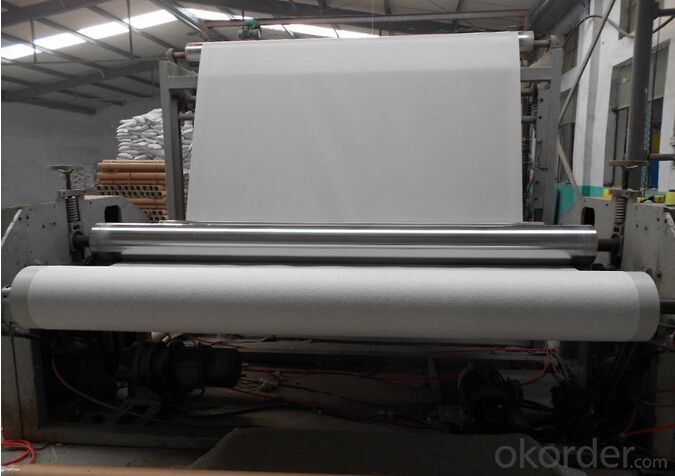

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

Polyvinyl chloride (PVC) waterproofing membrane is a macromolecule waterproofing membrane with superior performance. It is mainly made of polyvinyl chloride resin added with aid agents and aging resistance elements and produced by advanced plants and techniques. It has the characteristics such as superior tensile strength, good elongation, less shrink ratio, excellent low temperature flexibility and long lifetime.

PERFORMANCE INDEX

Performance indicators of Polyvinyl chloride waterproofing membrane

S/N | Items | Units | Indicators | ||||||

H | L | P | G | GL | |||||

1 | Thickness of resin coated on the central mat ≥ | mm | - | 0.4 | |||||

2 | Tensile property | Max. tensile force ≥ | N/cm | - | 120 | 250 | - | 120 | |

Tensile strength≥ | mpa | 10.0 | - | - | 10.0 | - | |||

Elongation of max. tensile force≥ | % | - | - | 15 | - | - | |||

Elongation at break≥ | % | 200 | 150 | - | 200 | 100 | |||

3 | Dimensional stability of hot treatment ≤ | % | 2.0 | 1.0 | 0.5 | 0.1 | 0.1 | ||

4 | Low temperature bending -25°C | No crack | |||||||

5 | Water tightness 0.3kpa, 2h | Impermeable | |||||||

PRODUCT FEATURES

Long lifetime and aging resistance. Lifetime of waterproofing membrane used on the roof is 20 years and that of waterproofing membrane underground.

Superior tensile strength, excellent elongation and less dimensional variation after hot treatment.

Superior low temperature flexibility and good performance suitable for environmental temperature change

Strong resistance to root puncture to be used for the roof

Excellent non-inflammability and self-quenching performance

Mildew resistance and efficient resistance to microbe damage

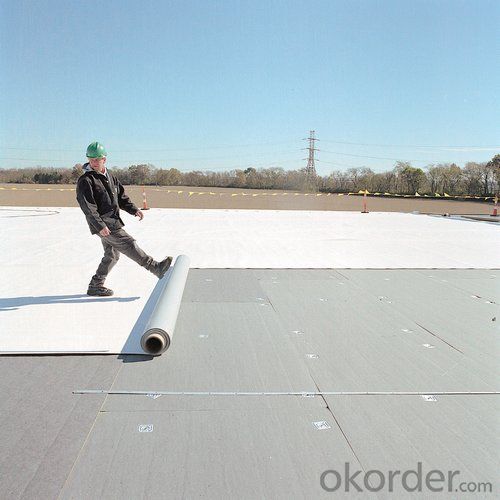

Easy installation, stable welding and friendly to environment

Strong chemical resistance and applied to special condition

Excellent modeling property and quick treatment to the corner

Convenient maintenance with low cost

RFQ

1. What is your MOQ?

--Our MOQ is 5000 m2

2. Can you provide sample?

--Yes, samples are in stock. we can offer free sample for you.

3. Do you offer OEM service?

--Yes, we can print customers’ logo on the packaging;

And the size and specification can be produced and design according to your demand.

- Q: Can a waterproofing membrane be used for elevator shafts?

- Yes, a waterproofing membrane can be used for elevator shafts. Elevator shafts can be susceptible to water infiltration, especially in locations with high water table or prone to flooding. A waterproofing membrane acts as a protective barrier against water penetration, helping to prevent damage to the elevator shaft and its components. It is an effective solution to ensure the longevity and proper functioning of elevator systems in such conditions.

- Q: Are there any specific considerations for installing a waterproofing membrane on concrete surfaces?

- Yes, there are several specific considerations when installing a waterproofing membrane on concrete surfaces. Firstly, it is important to ensure that the concrete surface is clean, dry, and free from any loose particles or contaminants. Proper surface preparation is crucial to allow for proper adhesion of the membrane. Secondly, it is essential to choose a suitable waterproofing membrane that is specifically designed for use on concrete surfaces, as different materials may have different compatibility and performance characteristics. Additionally, the correct application technique and thickness of the membrane should be followed as per the manufacturer's instructions. Finally, it is important to consider factors such as expansion joints, cracks, and structural movement, as these can affect the overall effectiveness and durability of the waterproofing system.

- Q: Does a waterproofing membrane prevent efflorescence or mineral deposits on surfaces?

- Yes, a waterproofing membrane can help prevent efflorescence or mineral deposits on surfaces. The membrane acts as a barrier, preventing water from entering the surface and carrying dissolved minerals or salts that cause efflorescence. By keeping the surface dry, the membrane helps to minimize the formation of mineral deposits.

- Q: Can a waterproofing membrane be used on adobe block surfaces?

- Indeed, adobe block surfaces can be treated with a waterproofing membrane. These blocks, composed of a blend of clay, sand, and straw, are prone to water damage. By applying a waterproofing membrane, the infiltration of water can be prevented, thus safeguarding the adobe blocks against various moisture-related problems like cracking, erosion, or mold formation. It is essential to verify that the waterproofing membrane is suitable for adobe surfaces and adhere to the manufacturer's instructions for application. Furthermore, prior to applying the membrane, it is vital to adequately prepare the surface and address any preexisting damages to ensure optimal performance.

- Q: Can a waterproofing membrane be installed on any surface?

- A waterproofing membrane can generally be installed on a variety of surfaces, but there are some factors to consider. The suitability of the surface depends on its condition, composition, and the type of waterproofing membrane being used. Typically, waterproofing membranes are designed to adhere to various substrates such as concrete, wood, metal, and masonry. They can be applied to surfaces like roofs, foundations, basements, bathrooms, and balconies. However, it is crucial to ensure that the surface is clean, dry, and free from any contaminants, such as dirt, debris, or loose materials, before installing the membrane. Furthermore, certain surfaces may require additional preparatory work or primers to enhance adhesion and ensure a long-lasting waterproofing solution. For example, rough or uneven surfaces might need to be leveled or smoothed out before the membrane can be applied. It is also important to consider the specific requirements of the waterproofing system being used. Different membranes have different application methods and compatibility with different surfaces. Some membranes may be more suitable for horizontal surfaces like flat roofs, while others may be better suited for vertical surfaces such as walls or foundations. Ultimately, it is recommended to consult with a professional waterproofing contractor or refer to the manufacturer's guidelines to determine the compatibility of the waterproofing membrane with a specific surface and to ensure proper installation for optimal performance and longevity.

- Q: Can a waterproofing membrane be installed in cold weather?

- Installing a waterproofing membrane in cold weather can present challenges. The freezing temperatures can affect the adhesion and curing process, potentially impacting the membrane's effectiveness. Therefore, it is important to observe the manufacturer's instructions and take extra precautions when working in cold weather conditions. To ensure successful installation, it is advisable to use a waterproofing membrane specifically designed for cold weather. These membranes are formulated with additives that enhance their adhesion and flexibility in low temperatures. Moreover, the temperature of the substrate should be considered during installation. It is crucial for the surface where the membrane will be applied to be above freezing temperature to ensure proper adhesion. In cases where the substrate temperature is too low, external heating methods like heat guns or warm air blowers may be necessary to warm the surface and achieve proper adhesion. Additionally, proper storage of the membrane prior to installation is vital in cold weather conditions. To prevent brittleness or loss of flexibility, the membrane should be stored in a warm environment. In conclusion, while it is possible to install a waterproofing membrane in cold weather, it is essential to take necessary precautions, use membranes designed for cold weather, and adhere to the manufacturer's guidelines to ensure proper adhesion and effectiveness.

- Q: Can waterproofing membranes be installed on uneven surfaces?

- Yes, waterproofing membranes can be installed on uneven surfaces. However, to ensure effective installation, it is important to properly prepare the surface by leveling or smoothing it out as much as possible before applying the membrane.

- Q: Roof SBS waterproofing membrane additional layer needs to be wide

- Roof SBS waterproofing membrane additional layer width of 15-20cm, angle attached layer 25cm on each side. Waterproof membrane is mainly used for building walls, roofs, as well as tunnels, highways, landfills, etc., to resist the external rain, groundwater leakage can be curled into a roll of flexible building materials, as the basis for engineering And no leakage between the building connection, the entire project is the first waterproof barrier, the entire project plays a vital role. The main products are asphalt waterproofing membrane and polymer waterproofing membrane.

- Q: Can waterproofing membranes be used on concrete floors?

- Yes, waterproofing membranes can be used on concrete floors. Waterproofing membranes are commonly used in construction to prevent water penetration and protect the underlying structure. When applied to concrete floors, these membranes create a barrier that prevents water from seeping through and causing damage. Waterproofing membranes can be particularly useful in areas such as basements, bathrooms, and outdoor patios where water exposure is common. They help to maintain the integrity of the concrete floor and protect it from moisture-related issues like cracking, spalling, and mold growth.

- Q: Can a waterproofing membrane be used in areas with high groundwater levels or flooding?

- Yes, a waterproofing membrane can be used in areas with high groundwater levels or flooding. Waterproofing membranes are designed to provide a barrier against water penetration, making them suitable for such conditions. They can effectively protect structures from water damage and prevent moisture infiltration, even in areas with high water tables or frequent flooding.

Send your message to us

Polyvinyl Chloride (PVC) Waterproofing Membrane with UV Resistance

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords