Polyvinyl Chloride (PVC) New Polymer Waterproofing Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Introduction of PVC Waterproofing Membrane

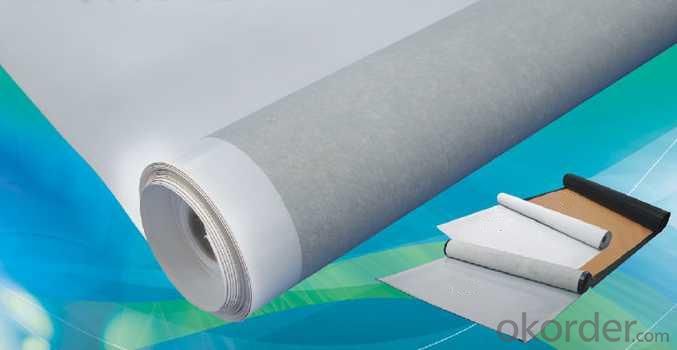

Polyvinyl Chloride (PVC) waterproof membrane is a new polymer waterproof membrane which is made from polyvinyl chloride resin, and mixed with plasticizer, filler, antioxygen, ultraviolet absorber and other auxiliaries.

2. Features of PVC Waterproofing Membrane

1) Excellent aging resistance. Service life of roofing material is over 20 years;

service life of underground material is over 50 years.

2) Root resistant penetration, specially used on planting roof.

3) Welding installation. Joints are solid and environment friendly, no pollution.

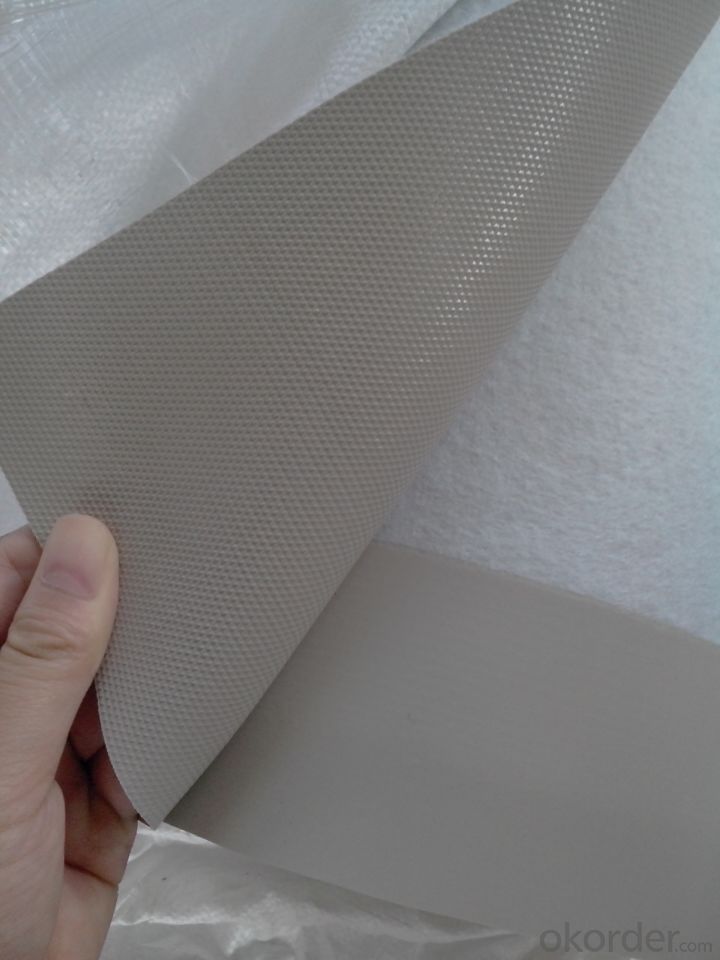

4) High tensile strength, good elongation and dimensional stability.

5) Good plasticity, easy and suitable for details installation.

6) Fireproof. Fire extinguished out of the ignition resource.

7) Surface is smooth, no fading and dirty resistant.

3. Specification of PVC Waterproofing Membrane

Length | 20m/roll or customized |

Width | 2.05m |

Thickness | 1.2mm; 1.5mm; 2.0mm |

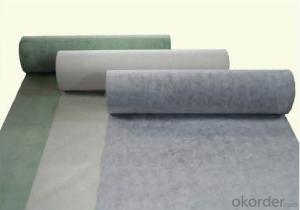

Type | Homogeneous, Reinforced, Fabric back |

If Exposed | Exposed and Non-exposed |

Color | White, Grey or customized |

4. Types of PVC Waterproofing Membrane

N1—Exposed PVC waterproof membrane.

(It is mainly used as details treatment for exposed roof waterproof project)

N2—Non-exposed PVC waterproof membrane.

(It is mainly used as details treatment for non-exposed roof waterproof project)

L1—Exposed PVC waterproof membrane with fabric.

(It is mainly used for exposed roof waterproof project)

L2—Non-exposed PVC waterproof membrane with fabric.

(It is mainly used for non-exposed roof waterproof project)

W1—Exposed reinforced PVC waterproof membrane .

(It is mainly used for steel structure roof exposed waterproof project)

W2—Exposed reinforced PVC waterproof membrane .

(It is mainly used for steel structure roof non-exposed waterproof project)

5. FAQ of PVC Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Can waterproofing membranes be used on roofs with slopes?

- Yes, waterproofing membranes can be used on roofs with slopes. These membranes are designed to provide a protective barrier against water infiltration and are commonly used on roofs with varying degrees of slope to prevent leaks and water damage.

- Q: Can a waterproofing membrane be installed by a DIYer?

- Yes, a waterproofing membrane can be installed by a DIYer. However, it is essential to follow the manufacturer's instructions carefully and have a basic understanding of the process. Additionally, the DIYer should possess the necessary skills and tools required for the installation. It is advisable to conduct thorough research and consider the complexity of the project before attempting it as improper installation can lead to ineffective waterproofing.

- Q: Can a waterproofing membrane be used on metal block surfaces?

- Yes, a waterproofing membrane can be used on metal block surfaces. Waterproofing membranes are designed to create a barrier against water and moisture, and they can be applied to a variety of surfaces, including metal. The membrane will adhere to the metal surface, creating a waterproof layer that helps prevent water infiltration and protect the metal from rusting or corrosion. However, it is important to ensure that the metal surface is clean, dry, and properly prepared before applying the waterproofing membrane to ensure proper adhesion and effectiveness. Additionally, it is recommended to consult with a professional or refer to the manufacturer's instructions for specific guidance on using a waterproofing membrane on metal block surfaces.

- Q: Can a waterproofing membrane be used on precast copper surfaces?

- Yes, a waterproofing membrane can be used on precast copper surfaces. Waterproofing membranes are versatile and can be applied on a variety of surfaces, including copper. These membranes are designed to create a barrier that prevents water penetration and protects the underlying structure from moisture damage. When applied correctly, a waterproofing membrane can effectively seal precast copper surfaces, providing long-lasting protection against water intrusion. However, it is important to ensure that the membrane is compatible with copper and that proper surface preparation is done before application to ensure optimal adhesion and performance.

- Q: Is a waterproofing membrane resistant to freeze-thaw cycles?

- Yes, a waterproofing membrane is typically resistant to freeze-thaw cycles. The membrane is designed to withstand extreme temperature changes without compromising its waterproofing capabilities.

- Q: Can a waterproofing membrane be used for convention centers or exhibition halls?

- Yes, a waterproofing membrane can definitely be used for convention centers or exhibition halls. These types of buildings often have large areas of flat roofs or underground spaces that are prone to water leakage. A waterproofing membrane is a durable and effective solution to prevent water infiltration and protect the structure from potential damage. Convention centers and exhibition halls are subject to heavy foot traffic and can experience high levels of moisture due to the presence of various activities, such as trade shows, concerts, and conferences. Waterproofing membranes provide a seamless and watertight barrier that effectively keeps water out, ensuring the integrity and durability of the building. Additionally, waterproofing membranes can be applied to different types of surfaces, including concrete, metal, and wood, making them suitable for various construction materials commonly used in convention centers and exhibition halls. They can be installed underneath flooring systems, on walls, or as a protective layer on roofs, providing comprehensive water protection for the entire structure. Moreover, waterproofing membranes come in different forms, such as liquid-applied membranes, sheet membranes, or spray-applied coatings. This versatility allows for flexibility in choosing the most appropriate type of membrane based on the specific requirements and conditions of the convention center or exhibition hall. In summary, a waterproofing membrane is an excellent choice for convention centers or exhibition halls due to its ability to prevent water penetration, protect the structure from potential damage, and ensure the longevity of the building.

- Q: Does a waterproofing membrane require any protective coatings or sealants?

- In order to enhance its performance and durability, a waterproofing membrane typically needs some form of protective coatings or sealants. While the membrane itself provides waterproofing to some extent, it may not be enough to withstand all environmental conditions or potential damage. To create an extra barrier against water intrusion, UV radiation, mechanical stress, and chemical exposure, it is advisable to apply protective coatings or sealants on top of the membrane. These coatings or sealants also offer additional flexibility, strength, and protection against wear and tear. To determine the suitable type of coating or sealant for the specific membrane and project requirements, it is essential to seek advice from a professional waterproofing specialist.

- Q: Does a waterproofing membrane require a topcoat or sealer?

- Yes, a waterproofing membrane typically requires a topcoat or sealer in order to provide additional protection and enhance its effectiveness. While the membrane itself is designed to prevent water penetration, applying a topcoat or sealer can further reinforce its waterproofing capabilities and extend its lifespan. The topcoat or sealer acts as an extra layer of defense against moisture, UV rays, and other potential sources of damage. Additionally, it can help seal any small cracks or imperfections in the membrane, ensuring a tighter seal and reducing the risk of water infiltration. Therefore, while a waterproofing membrane can offer some level of protection on its own, the addition of a topcoat or sealer is generally recommended for optimal performance and longevity.

- Q: How does a waterproofing membrane handle exposure to high temperatures?

- A waterproofing membrane is designed to withstand exposure to high temperatures. It is typically made from durable materials such as bitumen, EPDM (ethylene propylene diene monomer), or PVC (polyvinyl chloride) that have high melting points and can resist heat. These materials have been specifically chosen to ensure that the waterproofing membrane does not degrade or lose its effectiveness when exposed to high temperatures. The membrane's ability to handle high temperatures is dependent on its composition and quality. High-quality waterproofing membranes are manufactured with additives and fillers that enhance their resistance to heat. These additives help the membrane maintain its integrity and prevent it from softening, melting, or becoming brittle when exposed to elevated temperatures. Furthermore, the installation process of the waterproofing membrane also plays a crucial role in its ability to handle high temperatures. Proper installation techniques, such as ensuring proper adhesion and seam sealing, are essential to maintain the membrane's effectiveness and prevent any potential damage caused by heat exposure. In summary, a waterproofing membrane is specifically designed to handle exposure to high temperatures. Its composition, quality, and installation techniques all contribute to its ability to withstand heat without degrading or losing its waterproofing properties.

- Q: Is a waterproofing membrane resistant to extreme weather conditions?

- Yes, a waterproofing membrane is designed to be resistant to extreme weather conditions. It provides a protective barrier against heavy rain, snow, and intense sunlight, ensuring that it remains intact and effective in preventing water infiltration and damage to the underlying structure.

Send your message to us

Polyvinyl Chloride (PVC) New Polymer Waterproofing Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords