EPDM Waterproofing Membrane for Construction Field

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

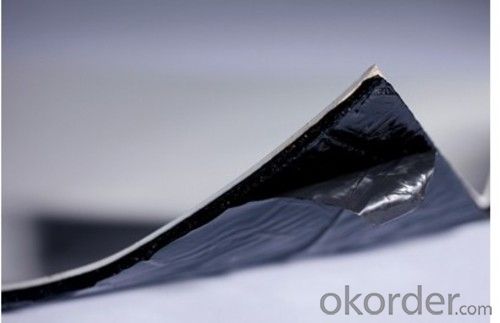

Brief Introduction:

This waterproof membrane is made from ternary ethylene-propylene rubber. Weadopts the world advanced equipment of cold feeding extrusion and continuous valcanization technology.

With the best performance among high polymer waterproof materials, EPDM is of exceptional elasticity and will not split or crack under normal building movement.

Specification:

Tensile Strength N/CM | Normal temperature: 60 ; 60°C: 30 |

Breaking Elongation % | Normal temperature: 400 ; -20°C: 10 |

Tear Resistance N | 20 |

Impermeability, 30 min no leakage | 0.3Mpa |

Low Temperature Bending °C | -20 |

Heating Shrinking mm | Extension: 2 Shrink: 4 |

Heat Resistance (80°C×168h) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:70 |

Alkali resistance (10% ca (oh)2 solution,normal temperature ×168h)) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

Synthetic aging | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

Characteristic:

1)Good flexibility, creep properties and malleability, and the superior adapting ability to the deformation of the primary stress generated.

2). Tight adhesion between waterproof layer and basic layer, no channeling water. Having self healing ability after piercing.

3).Operation without heating. And possessing the reliability of pasting by itself with super strong connection of sheet materialand adhesion of same base.

4). Convenient and safe operation, no pollution to the environment.

Application:

1) Make sure the roof deck smooth,clean and dry(Moisture<9%),then apply the surface of roof deck homogeneously with a kind bitumen paint till dry to start application.

2) There are two methods in application:

One way is by heating and melting method---Heat the polyethylene film of the membrane and roof deck surface by heating and melting method to be nearly melted(not flowing),then install the membrane fully bonded to the roof deck with overlaps of 5-10cm.

The other way is by cold adhesive method---Pour the cold adhesive homogeneously on the roof deck then roll the membrane to install it to be fully sticked to roof deck.

By heating and melting method and by cold adhesive can be used in alternation in application as requested.

3) After application,a full serious inspection is required to make sure no air bubble,no fold,no falling away etc to guarantee the waterproof life

FAQ of Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Can a waterproofing membrane be painted over?

- Indeed, painting over a waterproofing membrane is possible. Nevertheless, it is crucial to guarantee the cleanliness, dryness, and absence of any debris or loose substances on the membrane prior to applying paint. Furthermore, it is advised to employ a paint specifically formulated for waterproofing membranes in order to achieve proper adhesion and durability. It is equally essential to adhere to the manufacturer's guidelines for both the waterproofing membrane and the paint to ensure compatibility and effectiveness.

- Q: Can a waterproofing membrane be used on sloped surfaces?

- Using a waterproofing membrane on sloped surfaces is not only possible but highly recommended. This is because it effectively prevents water infiltration and potential damage. The main purpose of the membrane is to act as a barrier against water. When installed correctly, it can effectively safeguard sloped surfaces such as roofs, balconies, and retaining walls. The flexibility of the membrane allows it to conform to the shape of the slope, ensuring complete coverage and a tight seal. Some waterproofing membranes even come with self-adhesive properties or reinforcement layers specifically designed for sloped surfaces, making them even more effective. Ultimately, using a waterproofing membrane on sloped surfaces is a reliable method to ensure long-lasting protection against water damage.

- Q: Can a waterproofing membrane be used in conjunction with energy-efficient building designs?

- Yes, a waterproofing membrane can be used in conjunction with energy-efficient building designs. In fact, it is often recommended to have a waterproofing membrane as part of energy-efficient building designs, as it helps to protect the building from moisture infiltration and potential damage. By preventing water penetration, the membrane helps maintain the integrity of the building envelope, thus optimizing the energy performance and overall efficiency of the structure.

- Q: Can a waterproofing membrane be used in elevator pits or sump pits?

- Yes, a waterproofing membrane can be used in elevator pits or sump pits. Elevator pits and sump pits are prone to water infiltration, and a waterproofing membrane can effectively prevent water from seeping into these areas. The membrane acts as a barrier, preventing any water from entering the pit and causing damage to the elevator or pumping system. This helps to maintain the integrity of the elevator or pump and prolong its lifespan. Additionally, a waterproofing membrane can also protect the surrounding structures and prevent any water damage. It is important to select a suitable waterproofing membrane that is designed for below-ground applications and has the necessary properties to withstand the specific conditions in an elevator or sump pit.

- Q: Are waterproofing membranes suitable for residential applications?

- Yes, waterproofing membranes are suitable for residential applications. They are commonly used in various areas of residential construction, such as basements, foundations, roofs, bathrooms, and balconies, to prevent water penetration and protect the building structure from moisture damage. Waterproofing membranes provide a barrier against water, preventing it from seeping into the structure and causing issues like mold, rot, or structural damage. These membranes are typically made of materials like bitumen, PVC, EPDM, or polyurethane, which are highly effective in repelling water. In residential constructions, waterproofing membranes are installed during the building process or as a part of renovation projects. They can be applied as a liquid coating or in the form of sheets that are laid down and adhered to the surface. These membranes create a seamless and durable barrier that can withstand the test of time. Additionally, waterproofing membranes offer various benefits for residential applications. They help maintain a dry and comfortable living environment by preventing water leaks and dampness. This, in turn, protects the integrity of the building materials, prolongs the lifespan of the structure, and reduces the risk of costly repairs. Furthermore, waterproofing membranes can also enhance energy efficiency by reducing moisture-related heat loss or gain. By preventing water infiltration, they help maintain consistent temperatures inside the house, resulting in lower energy consumption and utility bills. Overall, waterproofing membranes are an excellent choice for residential applications. They provide reliable protection against water damage, improve the longevity of the structure, and contribute to a healthier and more energy-efficient living environment.

- Q: Are waterproofing membranes resistant to gasoline?

- Yes, waterproofing membranes are generally resistant to gasoline. Most waterproofing membranes are designed to be chemically resistant and can withstand exposure to various chemicals, including gasoline. However, it is important to note that the level of resistance can vary depending on the specific type of membrane and its composition. Some membranes may offer better resistance to gasoline than others. Additionally, prolonged exposure to gasoline can still potentially damage or degrade the membrane over time, so it is always recommended to take necessary precautions and avoid prolonged exposure to harsh chemicals.

- Q: Can a waterproofing membrane be used in conjunction with expansion joint systems?

- The use of a waterproofing membrane can be combined with expansion joint systems. These membranes are frequently employed to prevent the infiltration of water and safeguard structures against moisture damage. In contrast, expansion joint systems are put in place to enable movement and accommodate thermal expansion and contraction in structures. By utilizing both a waterproofing membrane and expansion joint systems, it is feasible to provide both waterproofing and movement accommodation in a structure. This guarantees that the structure is shielded from water damage while still permitting necessary movement. It is crucial to design and install both the waterproofing membrane and the expansion joint system properly to ensure their compatibility and effectiveness.

- Q: Does a waterproofing membrane have any fire resistance properties?

- Generally, a waterproofing membrane does not possess any fire resistance properties. Its primary function is to create a barrier against water infiltration and safeguard the underlying structure from moisture-related harm. Conversely, fire resistance pertains to a material's capacity to endure fire or hinder the propagation of flames. Specialized fireproofing materials or coatings typically possess fire resistance properties and are specifically engineered to prevent fire spread and safeguard the structure during fire incidents. When choosing construction materials, it is crucial to consider both fire resistance and waterproofing prerequisites as they serve distinct purposes and may necessitate separate measures to ensure safety.

- Q: Can a waterproofing membrane be used in conjunction with tile or stone installations?

- Certainly! When installing tile or stone, it is highly recommended to utilize a waterproofing membrane. This membrane serves as a barrier, preventing water from seeping into the underlying layers and causing damage. It is especially beneficial in wet areas, such as bathrooms, showers, and kitchen backsplashes. There are different types of waterproofing membranes available, such as liquid-applied, sheet, and fabric membranes. These can be applied to the substrate before installing the tile or stone, creating a waterproof layer that keeps the area dry and free from water-related issues. In addition to safeguarding against water damage, a waterproofing membrane also helps to prevent the growth of mold and mildew, which can be detrimental to both the installation and the health of those using the space. It is essential to note that proper installation of the waterproofing membrane is crucial for its effectiveness. Following the guidelines and best practices provided by the manufacturer ensures a tight seal and complete coverage. Overall, integrating a waterproofing membrane with tile or stone installations is a prudent decision. It enhances the project's durability and longevity while providing peace of mind against potential water damage.

- Q: Is a waterproofing membrane compatible with different types of roofing materials?

- Yes, a waterproofing membrane is compatible with different types of roofing materials. A waterproofing membrane is a versatile solution that can be used on various roofing materials such as asphalt shingles, metal roofs, concrete roofs, and even flat roofs. The membrane is designed to provide a barrier against water penetration, regardless of the type of roofing material. It can be applied directly on the surface of the roof or as an underlayment before installing the roofing material. This compatibility ensures that the waterproofing membrane can be used effectively to protect and extend the lifespan of different types of roofs.

Send your message to us

EPDM Waterproofing Membrane for Construction Field

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords