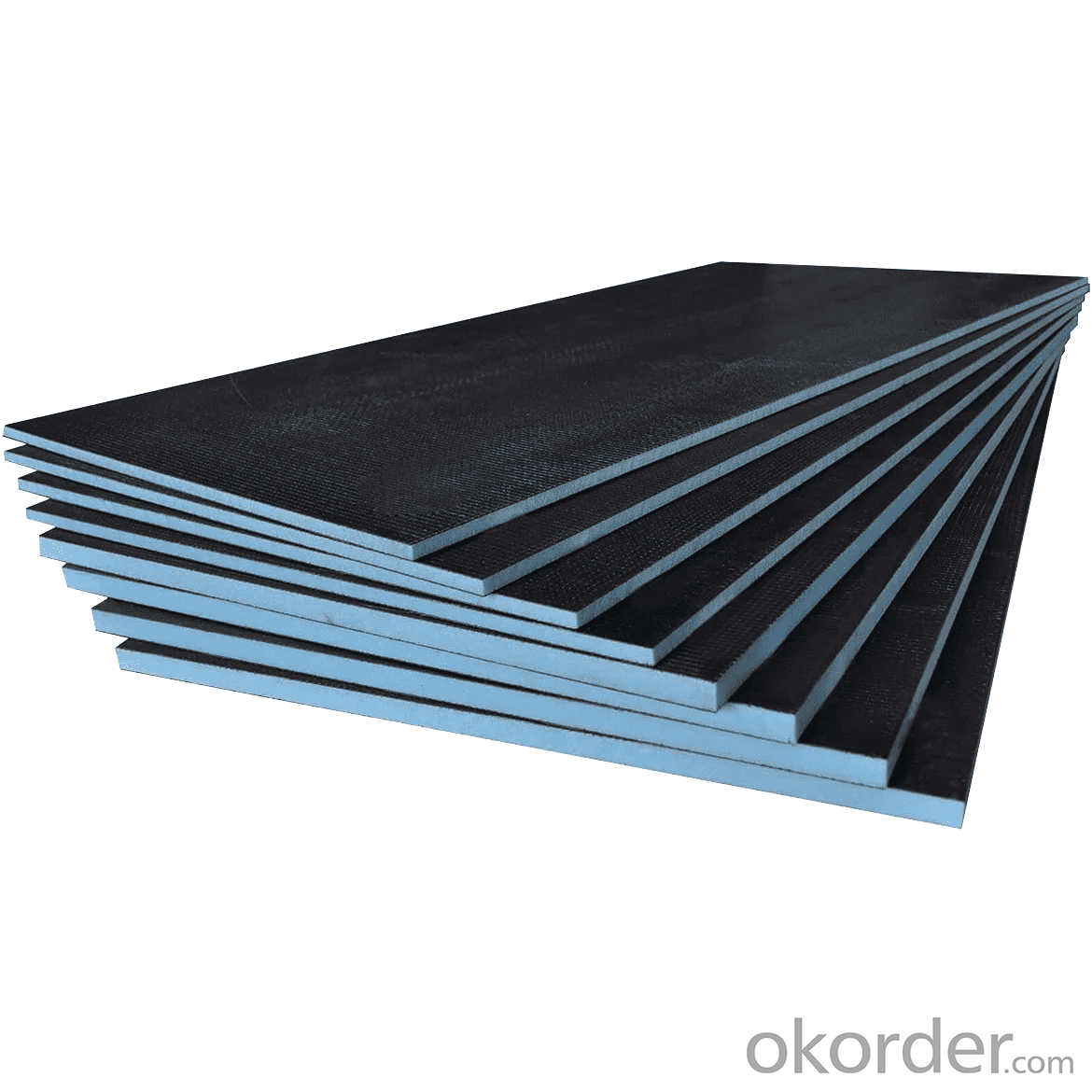

1200x600mm Wetroom 12mm Tile Backer Board For Walls and Floors

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Wetroom 12mm XPS Tile Backer Board For Walls and Floors 1200mm x 600mm (10 Pack)

When it comes to effective insulation solutions for your construction or tiling projects, XPS insulation boards are a reliable choice. We offer a wide range of XPS insulation boards, also known as XPS foam boards or simply XPS boards. These boards are designed to provide excellent thermal insulation, moisture resistance, and durability, making them ideal for various applications.

XPS insulation boards are constructed from extruded polystyrene foam, known for its high compressive strength and low thermal conductivity. This combination of properties makes XPS boards highly efficient in reducing heat transfer and improving energy efficiency in buildings. Whether you're insulating walls, floors, or roofs, XPS insulation boards offer a reliable solution.

Our selection of XPS foam boards includes various thicknesses and sizes to accommodate different project requirements. From smaller DIY projects to large-scale commercial installations, we have the right XPS insulation board to suit your needs. These boards are easy to handle and cut, allowing for precise fitting and installation.

Our company pride ourselves on providing high-quality products and exceptional customer service. Our knowledgeable staff are available to assist you in selecting the right XPS insulation board for your specific project. We also offer fast shipping and hassle-free returns to ensure your complete satisfaction with your purchase.

Whether you're a professional contractor or a DIY enthusiast, our XPS boards will help you create a comfortable and energy-efficient environment.

Performance parameters

Technical | Assessed to | Rating |

XPS Foam Density | DIN 53420 | 32±0.02kg/m³ |

Compressive strenghth (kPa) | EN 826 | ≥450 |

Thermal conductivity(W/m・K) | EN 12167 | ≤0.030 ≤0.034 |

Dimesional stability % (70±2℃) 48h | GB/T8811-2008 | ≤1.5 |

Flexural Strength (Mpa) | ASTM C203 | ≥2.8 |

Water Absorption(96hrs immersion) | ISO 2896 | ≤1.5 |

Water Vapour Permeability | ASTM E-96 | ≤3.0 |

Flammability | EN13501 | B2 |

Tensile strength perpendicular to the board | GB/T30595-2024 | ≥0.2Mpa |

Advantages

Advantages

1. impact resistant and rigid.

2. Waterproof and temperature resistant & Vapour retardant.

3. Thermally insulating.

4. Quick and easy to install.

5. Lightweight, easy to handle and transport.

6. Easy to cut (with a utility knife).

7. Applied to use on any kind of background substrate.

8. Applied to freestanding p

artition walls,shelves, coverings and similar surfaces.

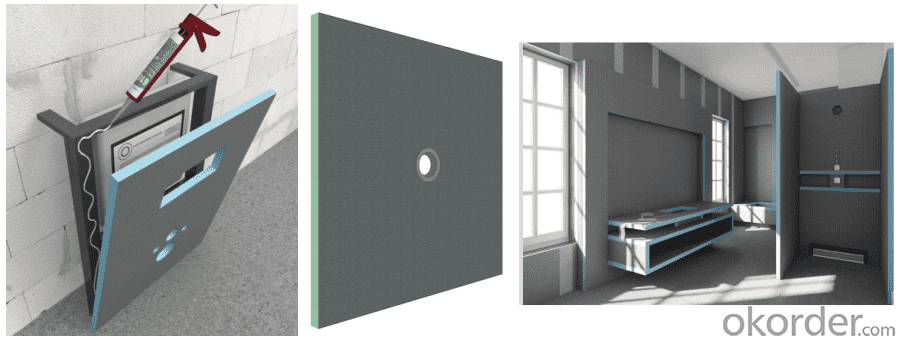

Applications

Bathrooms and Showers: Perfect for walls and floors in showers and bathrooms where water exposure is constant.

Kitchens: Ideal for kitchen backsplashes and countertops, providing a moisture-resistant base.

Wet Rooms: Suitable for creating fully waterproof wet rooms with tiled surfaces.

Exterior Spaces: Can be used in outdoor areas where moisture and temperature changes are a concern.

- Q: Can a waterproofing membrane be used for exterior foundation walls?

- Yes, a waterproofing membrane can be used for exterior foundation walls. Waterproofing membranes are designed to provide a protective barrier against water infiltration, and they are commonly used in construction to prevent moisture from entering below-grade structures such as foundation walls. These membranes are typically made of durable materials like rubber, asphalt, or polymer-based compounds that are resistant to water penetration. By installing a waterproofing membrane on the exterior side of foundation walls, it creates a barrier that prevents water from seeping into the foundation, which can help to prevent issues such as water damage, mold growth, and structural deterioration. Additionally, waterproofing membranes can also help to reduce the potential for cracks and leaks in the foundation, enhancing the overall durability and longevity of the structure.

- Q: Can a waterproofing membrane be applied on top of existing roofing systems?

- Yes, a waterproofing membrane can be applied on top of existing roofing systems. This is a common practice in the roofing industry to enhance the waterproofing capabilities of an existing roof. The application of a waterproofing membrane involves the installation of a layer of material that is designed to prevent water infiltration. This membrane can be made of various materials such as asphalt, rubber, or synthetic materials. Before applying the waterproofing membrane, it is important to assess the condition of the existing roofing system. Any damage or defects should be repaired to ensure a solid foundation for the membrane. Additionally, the surface should be thoroughly cleaned and prepared to ensure proper adhesion of the membrane. Once the surface is ready, the waterproofing membrane can be applied using various methods such as hot-mopping, torching, or adhesive application. The membrane is typically installed in multiple layers to provide additional protection against water penetration. Applying a waterproofing membrane on top of an existing roofing system can provide several benefits. It can extend the lifespan of the roof by preventing water damage and leaks. It can also improve the energy efficiency of the building by reducing heat transfer and minimizing air leakage. Additionally, it can enhance the overall waterproofing capabilities of the roof, protecting the underlying structure from moisture-related issues. It is important to consult with a professional roofing contractor to determine the most suitable waterproofing membrane and installation method for your specific roofing system. They will be able to assess the condition of the existing roof and recommend the best course of action to ensure a successful application of the waterproofing membrane.

- Q: Can a waterproofing membrane be used for a school?

- Yes, a waterproofing membrane can be used for a school. Waterproofing membranes are commonly used in various construction projects, including schools, to protect the building and its occupants from water damage. These membranes are typically applied to areas such as basements, roofs, and foundation walls to prevent water infiltration. By creating a barrier against moisture, a waterproofing membrane helps to maintain a dry and safe environment within the school, protecting against potential structural damage, mold growth, and other water-related issues. Additionally, waterproofing membranes often come with additional benefits such as insulation and soundproofing, which can contribute to a comfortable and conducive learning environment for students and staff.

- Q: Can a waterproofing membrane be used in conjunction with green building practices?

- Yes, a waterproofing membrane can definitely be used in conjunction with green building practices. In fact, incorporating a waterproofing membrane into the construction of a green building can help enhance its overall sustainability and efficiency. One of the key principles of green building practices is to maximize energy efficiency and reduce the environmental impact of a building. By installing a waterproofing membrane, the building's envelope can be protected from moisture intrusion, preventing water damage and potential mold growth. This, in turn, helps maintain the structural integrity of the building, reducing the need for repairs and replacements, which can be resource-intensive and generate waste. Additionally, a waterproofing membrane can contribute to better indoor air quality. By preventing water infiltration, it helps create a dry and healthy living or working environment, minimizing the risk of respiratory issues and other health problems associated with dampness. Furthermore, a waterproofing membrane can improve the energy efficiency of a building. By preventing water from seeping into the walls or foundation, it reduces the potential for heat loss through moisture evaporation, thus reducing the energy needed for heating and cooling. This can lead to reduced energy consumption and lower carbon emissions, aligning with the goals of green building practices. It is important, however, to choose a waterproofing membrane that is environmentally friendly and meets green building standards. Look for membranes that are made from recycled or sustainable materials and have low VOC (volatile organic compound) content. Additionally, consider selecting a membrane that is designed for durability and longevity, as this can further reduce the environmental impact by minimizing the need for replacement over time. In conclusion, a waterproofing membrane can be a valuable addition to any green building project. It helps protect the building envelope, improves indoor air quality, and enhances energy efficiency. By selecting an environmentally friendly membrane, the overall sustainability of the building can be further improved.

- Q: Can a waterproofing membrane be used on both interior and exterior surfaces?

- Both interior and exterior surfaces can benefit from the use of a waterproofing membrane. These membranes are created with the purpose of safeguarding surfaces against water infiltration and harm. Rubber, asphalt, or thermoplastic materials are commonly utilized to construct these membranes, which form a barrier to prevent moisture from penetrating. Whether applied to interior walls, floors, or exterior foundations, roofs, or balconies, a waterproofing membrane is highly effective in averting issues such as leaks, mold, or structural damage caused by water seepage. It is crucial to carefully consider the unique requirements of each surface and select an appropriate waterproofing membrane for the intended use.

- Q: Can a waterproofing membrane be installed in areas with high humidity?

- Yes, a waterproofing membrane can be installed in areas with high humidity. In fact, high humidity can be a contributing factor to the need for waterproofing as it can lead to moisture buildup and potential water damage. Waterproofing membranes are designed to create a barrier against water penetration, regardless of the humidity levels in the area. However, it is important to ensure that the membrane is properly installed and sealed to prevent any moisture from seeping through. Additionally, it may be necessary to take extra precautions in areas with high humidity, such as using a moisture barrier or dehumidifiers, to further protect against potential water damage.

- Q: Can waterproofing membranes be used on roofs?

- Yes, waterproofing membranes can be used on roofs. These membranes are designed to provide a barrier against water infiltration, protecting the roof structure and preventing leaks. They are commonly used in various types of roofs, including flat roofs, low-slope roofs, and even sloped roofs in certain cases. Waterproofing membranes offer excellent durability and flexibility, making them an effective solution for roof waterproofing.

- Q: Does a waterproofing membrane require any specific primers or bonding agents for installation?

- Yes, a waterproofing membrane often requires specific primers or bonding agents for proper installation. These primers or bonding agents are designed to ensure proper adhesion between the membrane and the substrate, enhancing the overall effectiveness and longevity of the waterproofing system. The type of primer or bonding agent required may vary depending on the specific membrane and substrate materials being used. It is important to consult the manufacturer's guidelines or seek advice from a waterproofing professional to determine the appropriate primer or bonding agent for your specific project to ensure a successful installation.

- Q: Does a waterproofing membrane provide any soundproofing benefits?

- A waterproofing membrane, unfortunately, does not offer any advantages in terms of soundproofing. Its sole purpose is to safeguard surfaces against water infiltration, such as roofs, walls, or foundations. It is typically composed of materials like asphalt, rubber, or polyethylene, which are not effective in obstructing or absorbing sound waves. On the other hand, soundproofing entails the utilization of distinctive materials and techniques that can diminish or eradicate the transmission of sound from one area to another. This may involve insulation, acoustic panels, or soundproof barriers. Consequently, if soundproofing is a concern, it is essential to contemplate separate soundproofing measures in conjunction with a waterproofing membrane.

- Q: Can waterproofing membranes be applied on roofs?

- Yes, waterproofing membranes can be applied on roofs. In fact, they are commonly used in the construction industry to provide an extra layer of protection against water infiltration. These membranes are typically made of synthetic materials such as PVC, TPO, or EPDM, which are highly resistant to water and can effectively prevent leaks and water damage on roofs. The application of waterproofing membranes on roofs is a proven method to enhance the longevity and durability of the roofing system, especially in areas prone to heavy rainfall or extreme weather conditions. Additionally, waterproofing membranes are flexible and can be easily installed on various types of roofing materials, including concrete, metal, or asphalt shingles. Therefore, if you want to ensure a watertight roof and protect your property from water-related issues, using waterproofing membranes is a reliable and effective solution.

Send your message to us

1200x600mm Wetroom 12mm Tile Backer Board For Walls and Floors

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Related keywords