EPDM Rubber Waterproof Membrane Width 1.2m Thickness1.2mm and 1.5mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description for EPDM Waterproof Membrane

EPDM waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-

popular waterproofing material. EPDM waterproof membrane is made from ternary ethylene-propylene

rubber, which is designed for waterproofing of exposed and non-exposed applications. EPDM waterproof

membrane production adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization

technology.

2. Features for EPDM Waterproof Membrane

1 Excellent physical and mechanical performance

2 High tearing resistance

3 Good deformation adaptability

4 High puncture resistance

5 High aging resistance

6 High UV resistance

3. Application for EPDM Waterproof Membrane

l Roofs, Basement, Toilet

l Industrial and civil building waterproofing

l Geosynthetic liner for swimming pool, channels, irrigation system

l Especially suit for projects with high requirements in durability, anti-corrosion and deformation

4 Specification for for EPDM Waterproof Membrane

Type | EPDM Waterproof Membrane | |||

Material | EPDM Rubber | |||

Thickness | 1.0mm | 1.2mm | 1.5mm | 2.0mm |

Size | 1.2m(width) * 20m(length)/roll | |||

Type | Vulcanized | |||

Pattern | Non-reinforced(homogeneous) | |||

Packing | 24sqm--80sqm/roll, with plastic bag | |||

Color | Black | |||

Application | Roofs, basement, pond, Lake, steel structure roof, swimming pool, underground, tunnel, etc | |||

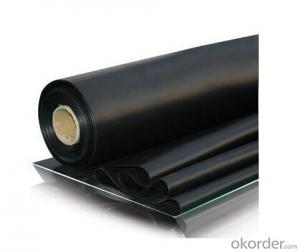

5. Image for EPDM Waterproof Membrane

6. FAQ

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane,

Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane,

Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

2.What's the main type for EPDM ?

Vulcanized and weldable are the main type .

3.What's the thickness for EPDM ?

1.2mm ,1.5mm ,2.0mm.

- Q: Can a waterproofing membrane be used in areas with high levels of salt or saltwater exposure?

- Indeed, areas with high levels of salt or saltwater exposure can benefit from the utilization of a waterproofing membrane. Nevertheless, it is imperative to opt for a membrane specifically engineered to endure these particular conditions. There exist certain waterproofing membranes that are specially concocted to resist the harmful effects of salt and saltwater exposure, effectively thwarting any potential harm or deterioration. Typically, these membranes are crafted using corrosion-resistant materials that possess heightened durability. To guarantee long-term efficacy and protection, it is absolutely crucial to seek professional guidance in selecting the appropriate type of waterproofing membrane for areas prone to high salt or saltwater exposure.

- Q: Are waterproofing membranes resistant to high temperatures?

- The resistance of waterproofing membranes to high temperatures may vary depending on the specific material utilized. Certain waterproofing membranes are specifically engineered to endure high temperatures while retaining their effectiveness and integrity. These membranes often comprise materials like modified bitumen or synthetic rubber, which possess properties that enable them to withstand elevated temperatures. Nevertheless, it should be noted that not all waterproofing membranes possess resistance to high temperatures. Some membranes constructed from PVC or other thermoplastic materials may have limitations when exposed to extreme heat. Therefore, it is imperative to refer to the manufacturer's specifications and guidelines to ensure that the selected waterproofing membrane is appropriate for the intended application and can endure the expected temperature conditions.

- Q: Can a waterproofing membrane be used in coastal areas?

- Yes, a waterproofing membrane can be used in coastal areas. Coastal areas are prone to high levels of moisture and water exposure, making it essential to have effective waterproofing measures in place. A waterproofing membrane, when properly installed and maintained, can provide a protective barrier against water intrusion, preventing damage to structures and ensuring their durability. However, it is important to select a membrane that is specifically designed for coastal environments, as these membranes are typically more resistant to saltwater and have enhanced durability to withstand the harsh coastal conditions. Additionally, regular inspection and maintenance should be carried out to ensure the effectiveness of the waterproofing membrane in coastal areas.

- Q: How does a waterproofing membrane handle seismic movements?

- A waterproofing membrane is designed to provide protection against water intrusion and leaks in structures such as buildings, basements, or roofs. While its primary function is to prevent water damage, it also plays a role in handling seismic movements to some extent. Seismic movements, or earthquakes, can cause significant stress and strain on structures, leading to cracks, fissures, or even the complete collapse of buildings. These movements generate intense vibrations and ground motion, which can compromise the integrity of waterproofing systems. In response to seismic movements, a properly installed waterproofing membrane is designed to be flexible and elastic. It can absorb and distribute the energy generated by the ground motion, minimizing the impact on the structure and reducing the likelihood of water infiltration. One way a waterproofing membrane handles seismic movements is through its ability to elongate and stretch. During an earthquake, the membrane can deform and accommodate the movement of the structure without tearing or breaking. This flexibility allows it to maintain its waterproofing capabilities even under extreme conditions. Additionally, waterproofing membranes often incorporate reinforcement layers, such as polyester or fiberglass, to enhance their tensile strength and resistance to tearing. These reinforcement layers help the membrane withstand the dynamic forces exerted during seismic events, ensuring its integrity and preventing water from seeping into the structure. It is important to note that while a waterproofing membrane can handle seismic movements to a certain extent, it is not a substitute for proper structural design and earthquake-resistant construction practices. Structures should be engineered to withstand seismic forces, and waterproofing systems should be installed in accordance with industry standards and guidelines to ensure their effectiveness and durability during earthquakes. In conclusion, a waterproofing membrane can handle seismic movements by being flexible, elastic, and resistant to tearing. It absorbs and distributes the energy generated by seismic events, protecting the structure from water infiltration and minimizing potential damage. However, it is essential to combine proper structural design and construction techniques with a reliable waterproofing system to ensure overall safety and resilience during earthquakes.

- Q: Can a waterproofing membrane be used on both interior and exterior surfaces of a structure?

- Yes, a waterproofing membrane can be used on both interior and exterior surfaces of a structure. Waterproofing membranes are designed to create a barrier that prevents water or moisture from penetrating into the structure, whether it is applied on the inside or outside. On the interior, a waterproofing membrane can be used to protect basements, crawl spaces, or other areas prone to moisture intrusion. This helps to prevent water damage, mold growth, and other issues that can arise from excess moisture in these spaces. On the exterior, a waterproofing membrane is commonly used to protect the foundation, walls, and other structural elements from water infiltration. This is especially important in areas with heavy rainfall or where the water table is high. By applying a waterproofing membrane on the exterior, it helps to keep the structure dry and prevents potential damage caused by water seepage. It is important to note that different types of waterproofing membranes are available for specific applications, so the selection of the appropriate membrane will depend on the specific requirements of the project.

- Q: Are waterproofing membranes resistant to hydrochloric acid?

- No, waterproofing membranes are generally not resistant to hydrochloric acid.

- Q: Can waterproofing membranes be used in basements?

- Basements can indeed benefit from the use of waterproofing membranes. These specialized membranes are designed specifically to act as a barrier against water penetration and are commonly employed in basements to effectively prevent moisture and water seepage. Typically composed of materials like rubber, bitumen, or polyethylene, these membranes are carefully applied to the walls and floors of the basement, creating an impermeable seal that keeps water out. By effectively stopping water from entering the basement, these membranes play a crucial role in safeguarding the foundation, walls, and interior spaces from the damaging effects of water, including mold and other moisture-related problems. Moreover, for comprehensive protection against water infiltration, waterproofing membranes can be utilized in conjunction with other waterproofing techniques like drainage systems and sump pumps.

- Q: Can a waterproofing membrane be used in areas with heavy foot traffic or vehicle loadings?

- In high-traffic or heavy loading areas, it is possible to utilize a waterproofing membrane. Nevertheless, it is crucial to select a membrane specifically designed for such purposes in order to guarantee durability and longevity. These specialized membranes are typically thicker and more resistant to wear and tear. Furthermore, it is important to consider the type of traffic or loading that the area will endure. For instance, areas with vehicular traffic may necessitate a membrane with higher compressive strength to endure the weight of vehicles. In conclusion, the selection of the appropriate type of membrane that satisfies the specific demands of the application is of utmost importance when using waterproofing membranes in high-traffic or heavy loading areas.

- Q: Construction Measures for Waterproof Coil in Winter

- 2. Master the hot melt paving points. Hot melt coil construction requirements of the heating width should be uniform, heating nozzle from the coil surface to be appropriate, 0.5m or so. Winter construction temperature is low, hot-melt time than the room temperature to be more, hot-melt to the surface of the membrane is bright, or melting is not enough. Such as beyond the degree of light overheating melting, the polymer modified asphalt easy to aging zoom, adverse bonding, but can not penetrate burned, grasp the hot melt to be strong bonding. When the sheet is rolled, the seam must be spilled over the adhesive to verify that the paste is tight, and the spilled adhesive is scrapped and the necessary measures to strengthen the seam. Coil large hot melt paving the same attention should be paid to the air inside the coil.

- Q: Can a waterproofing membrane be installed on a roof?

- Yes, a waterproofing membrane can be installed on a roof. A waterproofing membrane is a type of material that is specifically designed to provide a protective layer on a surface, preventing water from seeping through. When installed on a roof, a waterproofing membrane acts as a barrier against moisture, preventing leaks and water damage to the underlying structure. It is commonly used in flat or low-sloped roofs, where water can accumulate and cause issues. The installation process typically involves cleaning and preparing the roof surface, applying the membrane in overlapping layers, and securing it with adhesives, fasteners, or heat welding. Additionally, a waterproofing membrane can also help in extending the lifespan of a roof by protecting it from UV rays, temperature fluctuations, and other environmental factors. Overall, installing a waterproofing membrane on a roof is an effective way to ensure its long-term durability and prevent water-related problems.

Send your message to us

EPDM Rubber Waterproof Membrane Width 1.2m Thickness1.2mm and 1.5mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords