EPDM Rubber Waterproof Membrane for Thickness1.2mm/1.5mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. What's the Product ?

EPDM waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-

popular waterproofing material. EPDM waterproof membrane is made from ternary ethylene-propylene

rubber, which is designed for waterproofing of exposed and non-exposed applications. EPDM waterproof

membrane production adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization

technology.

2. Features for EPDM Waterproof Membrane

1 Excellent physical and mechanical performance

2 High tearing resistance

3 Good deformation adaptability

4 High puncture resistance

5 High aging resistance

6 High UV resistance

3. Application for EPDM Waterproof Membrane

l Roofs, Basement, Toilet

l Industrial and civil building waterproofing

l Geosynthetic liner for swimming pool, channels, irrigation system

l Especially suit for projects with high requirements in durability, anti-corrosion and deformation

4 Specification for for EPDM Waterproof Membrane

Type | EPDM Waterproof Membrane | |||

Material | EPDM Rubber | |||

Thickness | 1.0mm | 1.2mm | 1.5mm | 2.0mm |

Size | 1.2m(width) * 20m(length)/roll | |||

Type | Vulcanized | |||

Pattern | Non-reinforced(homogeneous) | |||

Packing | 24sqm--80sqm/roll, with plastic bag | |||

Color | Black | |||

Application | Roofs, basement, pond, Lake, steel structure roof, swimming pool, underground, tunnel, etc | |||

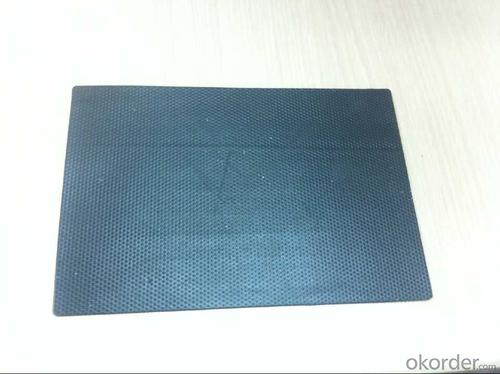

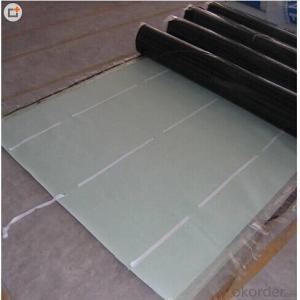

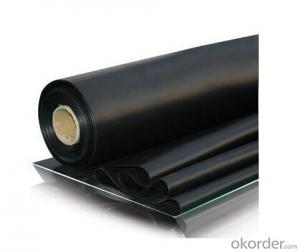

5. Image for EPDM Waterproof Membrane

5. Installations:

1. Adhere the EPDM membrane directly to the smooth and clean substrate like concrete deck, insulation board, etc.

2. Adjust membrane to make sure the overlaps is no less than 10cm and wiped clean.

3. Then, apply special adhesive evenly to both the substrate and the membrane laps or seam tape.

4. After minutes, press it securely and finish with sealant.

6. FAQ

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane,

Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane,

Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

2.What's the main type for EPDM ?

Vulcanized and weldable are the main type .

3.What's the thickness for EPDM ?

1.2mm ,1.5mm ,2.0mm.

- Q: Can a waterproofing membrane be applied on vertical surfaces?

- Indeed, vertical surfaces can be treated with a waterproofing membrane. It is common practice to utilize such membranes on exterior walls, retaining walls, and foundations in order to safeguard the underlying structure by averting water infiltration. These specialized membranes are formulated to adhere to vertical surfaces, serving as a moisture blockade. To guarantee optimal waterproofing performance, they are typically applied in multiple layers. Moreover, a wide range of waterproofing membranes are accessible, namely liquid-applied, sheet-applied, and spray-applied membranes, each of which can be customized to suit the specific vertical surfaces and construction needs.

- Q: How does a waterproofing membrane withstand freeze-thaw cycles?

- To endure freeze-thaw cycles, a waterproofing membrane is constructed using materials that resist temperature shifts and water infiltration. Typically, these membranes consist of robust polymers like polyurethane, polyethylene, or PVC, which have low water permeability and can withstand the expansion and contraction caused by freezing and thawing. Freeze-thaw cycles allow water to seep into small cracks and pores within a structure. As the water freezes, it expands, exerting pressure on the surrounding materials. This pressure can widen cracks and weaken the structure, resulting in water leakage and potential damage. However, a waterproofing membrane acts as a barrier, preventing water from infiltrating the structure and minimizing the risk of freeze-thaw damage. The membrane is applied to the exterior surface of the structure, forming a continuous and seamless layer that prohibits water passage. It adheres securely to the surface and possesses flexibility to accommodate dimensional changes caused by temperature fluctuations. Additionally, waterproofing membranes are often reinforced with fabrics or meshes to enhance their strength and stability. These reinforcements provide further protection against damage during freeze-thaw cycles, ensuring the long-term effectiveness of the membrane. In conclusion, a waterproofing membrane endures freeze-thaw cycles by impeding water infiltration and withstanding the expansion and contraction caused by freezing and thawing. Its composition, including durable polymers and reinforcements, establishes it as a dependable barrier against water penetration, reducing the likelihood of structural damage and upholding the integrity of the protected surface.

- Q: Can a waterproofing membrane be used on sloped roofs?

- Yes, a waterproofing membrane can be used on sloped roofs. Waterproofing membranes are designed to provide a protective barrier against water penetration, and their flexibility allows them to conform to the shape of sloped roofs effectively. This helps prevent water from seeping into the structure and causing damage.

- Q: Can a waterproofing membrane be used for zoos or aquariums?

- Zoos or aquariums can definitely utilize waterproofing membranes. These membranes are specifically designed to create a protective barrier against water infiltration, making them an excellent choice for preventing water damage and leakage in such environments. They can be applied to different surfaces, such as concrete or steel, to establish a watertight seal and prevent water from seeping into the structure or habitat. Aquariums often rely on waterproofing membranes to ensure that their tanks remain completely watertight and free from leaks, as this is crucial for the well-being of the aquatic animals. Similarly, in zoos, waterproofing membranes can be applied to animal enclosures or exhibit areas to safeguard the structures from water damage and uphold a safe and healthy environment for the animals. Moreover, these membranes possess resistance against various chemicals and can withstand harsh conditions, making them an excellent safeguard against potential chemical spills. All in all, waterproofing membranes are a highly suitable option for zoos or aquariums, as they offer an effective solution for preserving the integrity of the structures and habitats, averting water damage, and ensuring the safety and well-being of the animals.

- Q: How does a waterproofing membrane handle joint movement?

- To prevent water infiltration and maintain its effectiveness, a waterproofing membrane is specially crafted to handle joint movement. It accomplishes this by exhibiting flexibility and the ability to adapt to the expansion and contraction of joints. When joints experience movement due to factors like temperature fluctuations or settling of the structure, a waterproofing membrane must have the capability to stretch and compress without tearing or compromising its waterproofing properties. This is typically achieved through the utilization of elastomeric materials, such as rubber or synthetic polymers, which boast exceptional elongation and recovery properties. Moreover, waterproofing membranes may incorporate reinforcing materials, such as fabric or mesh, to enhance their tensile strength and their capacity to withstand joint movement. These reinforcements assist in distributing the stresses caused by joint movement, thus preventing localized damage and preserving the integrity of the membrane. Furthermore, certain waterproofing membranes possess special adhesive properties that enable them to tightly bond to the surfaces they are applied to, including the edges of joints. This adhesive bond plays a crucial role in establishing a continuous barrier against water penetration, even in the presence of joint movement. In summary, a waterproofing membrane is designed to exhibit flexibility and durability, ensuring effective management of joint movement, long-term protection against water intrusion, and the preservation of the structural integrity of the building or structure.

- Q: Does a waterproofing membrane require any protective coatings or sealants?

- No, a waterproofing membrane typically does not require any additional protective coatings or sealants as it is designed to be a standalone barrier against water penetration.

- Q: Can waterproofing membranes be installed on uneven surfaces?

- Waterproofing membranes possess the capability to be installed on surfaces that are not even. In reality, one of the benefits of these membranes is their ability to adapt to different irregularities and unevenness on the surface. Typically, these membranes are flexible and can be easily shaped and adjusted to fit the contours of the substrate. Furthermore, certain waterproofing membranes possess self-adhesive properties or can be applied with adhesives, enabling them to effectively stick to both smooth and uneven surfaces. Nevertheless, it is crucial to emphasize that proper surface preparation is essential for a successful installation. The surface must be clean, dry, and devoid of any loose materials or debris to ensure the optimum adhesion and performance of the waterproofing membrane.

- Q: Can a waterproofing membrane be used on tunnels with electrical installations?

- Yes, a waterproofing membrane can be used on tunnels with electrical installations. These membranes are designed to provide a protective barrier against water ingress, ensuring the safety and functionality of electrical installations in tunnels.

- Q: Can a waterproofing membrane be installed in areas with high humidity?

- Yes, a waterproofing membrane can be installed in areas with high humidity. In fact, high humidity can be a contributing factor to the need for waterproofing as it can lead to moisture buildup and potential water damage. Waterproofing membranes are designed to create a barrier against water penetration, regardless of the humidity levels in the area. However, it is important to ensure that the membrane is properly installed and sealed to prevent any moisture from seeping through. Additionally, it may be necessary to take extra precautions in areas with high humidity, such as using a moisture barrier or dehumidifiers, to further protect against potential water damage.

- Q: Does a waterproofing membrane require any specific curing time before it can be exposed to water?

- Yes, a waterproofing membrane generally requires a specific curing time before it can be exposed to water. The curing time allows the membrane to fully dry, set, and create a strong bond with the substrate it is applied to. This ensures its effectiveness in preventing water penetration. The specific curing time can vary depending on the type of membrane and manufacturer's instructions, so it is crucial to follow the recommended curing period before subjecting it to water exposure.

Send your message to us

EPDM Rubber Waterproof Membrane for Thickness1.2mm/1.5mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords