EPDM Waterproof Rubber Membrane with 1.2mm Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Waterproof Rubber Membrane with 1.2mm Thickness

Description Of EPDM Waterproof Rubber Membrane with 1.2mm Thickness:

1. EPDM waterproof membrane is made from ternary ethylene-propylene rubber, which is for waterproofing of exposed and non-exposed applications.

2. EPDM waterproof membrane production adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization technology.

3. EPDM waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

Main Features of EPDM Waterproof Rubber Membrane with 1.2mm Thickness:

1.Excellent anti-aging performance, service life can reach 50 years;

2.High elongation, high tensile strength, heat treatment size change small;

3.Plant root penetration resistance is good

4.Good low temperature flexibility

5.Application is convenient, overlapping is firm and reliable, no environmental pollution;

6. Resistance to chemical corrosion, can be applied to special places;

7.Maintenance is convenient, the cost is low

Specifications of EPDM Waterproof Rubber Membrane with 1.2mm Thickness:

ITEM | STANDARO REQUEST | |

Tensile strength at breaking,normal temperature,Mpa | ≥7.5 | |

Elongation at breaking, % | ≥450 | |

Tearing strenght,KN/m | ≥25 | |

Bending at low temperature | ≤-40°C | |

Water impermeability,0.1Mpa×30min | Impermeability | |

Hot air aging 80°C×168h | Unchanging of tensile strength at breaking,% | ≥80 |

Unchanging of elongation at breaking,% | ≥70 | |

Appearance of 100% elongation | No crack | |

Property of anti alkali 10% Ca(OH)2×168h normal temperature | ≥80 | |

≥80 | ||

Applications of EPDM Waterproof Rubber Membrane with 1.2mm Thickness:

1.Roofs, Basement, Toilets

2. Industrial and civil building waterproofing

3. Geosynthetic liner for swimming pool, channels, irrigation system

4. Especially suitable for projects with high requirements in durability, anti-corrosion and deformation.

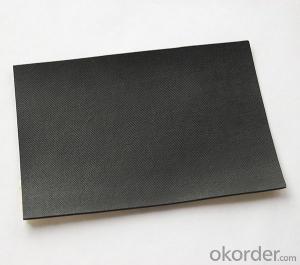

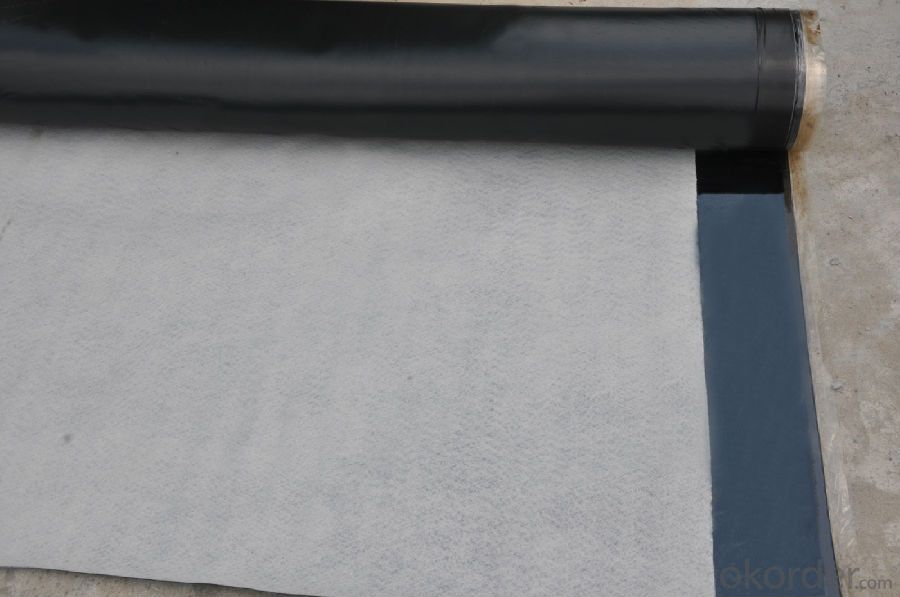

IMages of EPDM Waterproof Rubber Membrane with 1.2mm Thickness:

FAQ of EPDM Waterproof Rubber Membrane with 1.2mm Thickness:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Can a waterproofing membrane be used for underground storage facilities?

- Yes, a waterproofing membrane can be used for underground storage facilities. Waterproofing membranes are designed to prevent water infiltration, making them an ideal solution for underground structures such as storage facilities. These membranes are typically made from materials such as bitumen, rubber, or polyethylene, which are highly resistant to water penetration. By installing a waterproofing membrane on the walls and floor of an underground storage facility, it helps to create a barrier that prevents water from seeping in, protecting the stored goods from moisture damage. Additionally, waterproofing membranes also help to prevent the growth of mold and mildew, which can be detrimental to the integrity of the structure and the items stored within. Overall, using a waterproofing membrane is a reliable and effective way to ensure the durability and longevity of an underground storage facility.

- Q: Are waterproofing membranes resistant to frost damage?

- Waterproofing membranes, in general, exhibit resistance towards frost damage. These membranes are specifically crafted to endure diverse weather conditions, which include freezing temperatures. They typically comprise modified bitumen, PVC, EPDM, or TPO, materials renowned for their exceptional frost and environmental resistance. These materials are engineered to maintain their flexibility and elasticity, even in low temperatures, ensuring the preservation of the waterproofing membrane's effectiveness in preventing water infiltration. Furthermore, meticulous installation methods and regular maintenance can augment the waterproofing membranes' resistance to frost damage.

- Q: Can a waterproofing membrane be used on planter boxes?

- Yes, a waterproofing membrane can be used on planter boxes. A waterproofing membrane is typically used to prevent water from seeping through surfaces, and this can be beneficial for planter boxes as it helps to protect the wood or other materials from moisture damage. By applying a waterproofing membrane to the interior of the planter box, it creates a barrier that prevents water from penetrating the material and potentially causing rot or decay. This can extend the lifespan of the planter box and ensure that it remains in good condition for a longer period of time. Additionally, a waterproofing membrane can also help to retain moisture within the planter box, which can be beneficial for the plants or flowers that are being grown. Overall, using a waterproofing membrane on planter boxes can provide added protection and durability.

- Q: Can a waterproofing membrane be used for a commercial building roof?

- Yes, a waterproofing membrane can be used for a commercial building roof. Waterproofing membranes are commonly used in commercial roofing systems to provide a durable and effective barrier against water penetration. These membranes are designed to withstand the challenges of commercial buildings, such as exposure to the elements, foot traffic, and mechanical equipment. They offer excellent protection against leaks, moisture damage, and other potential roofing issues, making them a suitable choice for commercial applications.

- Q: Can a waterproofing membrane be used in swimming pools or other water features?

- Certainly, swimming pools or other water features can indeed utilize a waterproofing membrane. In fact, it is highly advisable to employ such a membrane in these areas to avert water leakage and potential harm. By serving as a barrier between the water and the surrounding structures, a waterproofing membrane ensures that the water remains contained within the pool or water feature. Not only does it prevent water seepage, which can inflict structural damage and necessitate expensive repairs, but it also safeguards the pool or water feature from the harsh chemicals employed for water treatment, thereby guaranteeing its durability and long lifespan. Consequently, the utilization of a waterproofing membrane is an essential measure in the construction or renovation of swimming pools or other water features, guaranteeing their functionality and longevity.

- Q: Can a waterproofing membrane be used on concrete block surfaces?

- Yes, a waterproofing membrane can be used on concrete block surfaces. Waterproofing membranes are designed to provide a barrier against moisture and water penetration, and they are commonly used on concrete block surfaces to protect against water damage and leaks. These membranes are typically applied as a liquid or sheet material and adhere to the surface of the concrete blocks, creating a protective layer that prevents water from seeping through. The waterproofing membrane helps to extend the lifespan of the concrete blocks by reducing the risk of water damage, mold growth, and deterioration. It is important to choose a waterproofing membrane that is specifically designed for concrete block surfaces and follow the manufacturer's instructions for proper installation to ensure the best results.

- Q: Can waterproofing membranes be used on outdoor patios?

- Yes, waterproofing membranes can be used on outdoor patios. They are an effective way to protect the patio from water damage and can help to prevent leaks and moisture penetration. Waterproofing membranes create a barrier between the patio surface and water, keeping it dry and extending its lifespan.

- Q: Do waterproofing membranes require maintenance?

- Yes, waterproofing membranes do require maintenance. Regular inspection and maintenance are necessary to ensure the effectiveness and longevity of the waterproofing system. This may include checking for any damages or wear and tear, clearing debris, ensuring proper drainage, and addressing any potential issues promptly.

- Q: Can waterproofing membranes be used on roof decks?

- Yes, waterproofing membranes can be used on roof decks. These membranes are specifically designed to provide a barrier against water penetration and protect the underlying structure from moisture damage. They are commonly used in roof deck construction to ensure a watertight and durable surface.

- Q: Can a waterproofing membrane be used on plaster surfaces?

- Yes, a waterproofing membrane can be used on plaster surfaces. It provides a protective barrier that prevents water penetration and helps to enhance the durability and longevity of the plaster surface.

Send your message to us

EPDM Waterproof Rubber Membrane with 1.2mm Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords