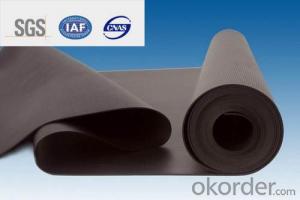

EPDM Waterproofing Roofing Membrane for Roof 1.2mm and 1.5mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of EPDM Rubber Waterproof Membrane:

1.EPDM Waterproof Membrane / Roofing Material / Sheets Roofing

2.High tensile strength.

3.Good elongation.

4.UV resistant.

5.Anti-corrosion.

Main Features of EPDM Rubber Waterproof Membrane:

1) Excellent weather-ability, durability and size stability

2) Good adaptability to high and low temperature, UV resistant and anti-corrosion

3) High tensile strength and good elongation, accommodating to structure movement

4) Easy installation, solid joint, and no environmental pollution

5) Good rooting penetration resistance

6) Service life up to 50 years

Specifications of EPDM Rubber Waterproof Membrane:

Material | EPDM Rubber |

Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

Thick | 1.2mm, 1.5mm, 2.0mm |

Type | Vulcanized & Weldable |

Pattern | Non-reinforced (homogeneous) |

Certificate | ISO9001/14001 |

Applications of EPDM Rubber Waterproof Membrane:

1) Roofs, Basement, Toilet

2) Industrial and civil building waterproofing

3) Geo-synthetic liner for swimming pool, channels, irrigation system

4) Especially suit for projects with high requirements in durability, anti-corrosion and deformation

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Waterproof building materials after the construction of drums, bubble is what reason?

- Reason 2: Construction, due to the construction of the membrane waterproof layer of paving is not true, so that part of the empty, remain in which to form a bubble. Control measures: in the asphalt waterproofing membrane construction, the first surface of the coil clean. When laying the web, the mastic should be painted evenly and carefully compaction work to enhance the cohesive force between the web and the base, the web and the web. High polymer modified asphalt waterproofing membrane construction, the flame heating to be uniform, full, moderate. Paving to roll forward while hot, while rolling with a pressure roller to exclude the air below the coil.

- Q: Can a waterproofing membrane be used on precast insulation surfaces?

- Yes, a waterproofing membrane can be used on precast insulation surfaces. A waterproofing membrane is designed to provide a protective barrier against water infiltration, and it can be applied to a variety of surfaces, including precast insulation. The membrane helps to prevent water from seeping into the insulation, which can cause damage and reduce its effectiveness. By applying a waterproofing membrane to precast insulation surfaces, you can ensure that the insulation remains dry and maintains its thermal properties over time.

- Q: Does a waterproofing membrane prevent water damage to building materials?

- A waterproofing membrane is specifically designed to shield building materials from water damage. Its purpose is to act as a barrier, preventing water from infiltrating the structure and causing harm. Typically, the membrane is applied to areas prone to water intrusion, such as roofs, basements, and foundations. By creating a watertight seal, it effectively stops water from seeping through and harming the building materials. This safeguard is essential in maintaining the structure's integrity and preventing issues like mold growth, rot, and material decay. However, it's crucial to acknowledge that the effectiveness of a waterproofing membrane can vary based on the product's quality and proper installation. Regular maintenance and inspections are also necessary to ensure the membrane remains intact and continues to safeguard against water damage.

- Q: Can a waterproofing membrane be used for a plaza deck waterproofing?

- Yes, a waterproofing membrane can be used for plaza deck waterproofing. Waterproofing membranes are specifically designed to provide protection against water intrusion, making them an ideal choice for plaza deck waterproofing applications. These membranes are durable, flexible, and can effectively prevent water damage to the underlying structure.

- Q: Can a waterproofing membrane be used for a swimming pool?

- Indeed, a swimming pool can benefit from the utilization of a waterproofing membrane. In the realm of construction, waterproofing membranes find frequent application in order to avert water infiltration and leakage. Once administered to both the walls and floor of a swimming pool, a waterproofing membrane establishes a protective barrier that thwarts the infiltration of water into the adjacent structures. This essential measure is imperative for upholding the pool's integrity and averting harm to the surrounding regions. Tailored specifically for swimming pools, waterproofing membranes are engineered to endure the perpetual exposure to water and chemicals, guaranteeing durable safeguarding.

- Q: Can a waterproofing membrane be used in laundry rooms?

- Yes, a waterproofing membrane can be used in laundry rooms. It is commonly used to protect against water damage and prevent leaks in areas where water is present, such as laundry rooms, bathrooms, and kitchens.

- Q: Can a waterproofing membrane improve energy efficiency?

- Indeed, energy efficiency can be enhanced through the utilization of a waterproofing membrane. By functioning as a barricade against the infiltration of moisture, the waterproofing membrane effectively averts water from permeating the building envelope. Consequently, it maintains the structure's dryness, thus inhibiting the growth of mold and mildew. This is pivotal in the preservation of indoor air quality and the safeguarding of building materials from deterioration. Furthermore, a waterproofing membrane can also offer insulation advantages. Numerous waterproofing membranes are engineered with a substantial thermal resistance, commonly referred to as R-value. This signifies that they can furnish an additional layer of insulation to the edifice, diminishing heat transfer across the walls and roof. By enhancing the thermal performance of the building, a waterproofing membrane facilitates the reduction of the burden placed on heating and cooling systems, ultimately leading to energy savings and improved energy efficiency. Moreover, a waterproofing membrane can contribute to the reduction of air leakage within a building. Air leakage is responsible for a noteworthy amount of energy dissipation, as conditioned air escapes through crevices and fissures in the building envelope. By effectively sealing off these areas, the waterproofing membrane aids in enhancing the airtightness of the building, thereby diminishing energy loss and improving energy efficiency. All in all, a waterproofing membrane assumes a pivotal role in the enhancement of energy efficiency by preventing moisture intrusion, providing supplementary insulation, and diminishing air leakage. Allocating resources towards a top-notch waterproofing system can result in long-term energy savings, improved indoor comfort, and a more sustainable and efficient building.

- Q: Can a waterproofing membrane be used for airport runways?

- Yes, a waterproofing membrane can be used for airport runways. Airport runways are subjected to a significant amount of wear and tear due to heavy aircraft traffic, weather conditions, and potential fuel spills. A waterproofing membrane can serve as a protective barrier against water infiltration, which can lead to runway deterioration and damage. It can also prevent the penetration of fuel, oil, and other chemicals that can weaken the runway structure. Additionally, a waterproofing membrane can help to prolong the lifespan of the runway by reducing the effects of freeze-thaw cycles and preventing the formation of cracks and potholes. Overall, the use of a waterproofing membrane can enhance the durability and safety of airport runways, ensuring smooth operations and minimizing maintenance costs.

- Q: Are waterproofing membranes UV resistant?

- Indeed, the majority of waterproofing membranes boast UV resistance. Given their frequent exposure to sunlight, UV resistance is a crucial attribute for these membranes. Over time, the degradation and deterioration caused by UV rays can significantly impair the effectiveness and durability of materials, necessitating the inclusion of UV-resistant additives or coatings by manufacturers. This incorporation of UV resistance safeguards the integrity and performance of the membrane, guaranteeing enduring protection against water infiltration.

- Q: Can a waterproofing membrane be used on tunnels with lighting systems?

- Yes, a waterproofing membrane can be used on tunnels with lighting systems. In fact, it is often necessary to use waterproofing membranes in tunnels to protect the structure from water infiltration. These membranes are designed to create a barrier that prevents water from seeping into the tunnel and causing damage. They are typically applied to the tunnel walls, floors, and ceilings and can be used in conjunction with lighting systems without any issues. The waterproofing membrane will not affect the functionality or safety of the lighting system and will help ensure that the tunnel remains watertight and protected from moisture-related issues.

Send your message to us

EPDM Waterproofing Roofing Membrane for Roof 1.2mm and 1.5mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords