1.0mm/1.2mm/1.5mm EPDM rubber roofing waterproof membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 8000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

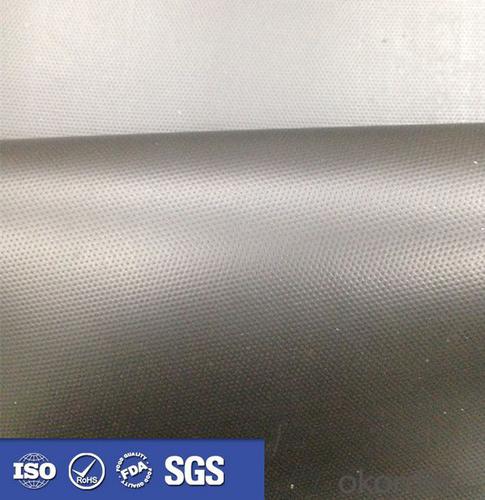

Description Of 1.0mm/1.2mm/1.5mm EPDM rubber roofing waterproof membrane:

Self adhesive waterproof rolling material:

thickness:1.2/1.5/2.0mm

length/roll:10/20m

width/roll:1.02m

Low temperature:-15 -20,-30

Main Features of 1.0mm/1.2mm/1.5mm EPDM rubber roofing waterproof membrane:

1) High tear

2) High puncturing strength

3) Great temperature resistance.

4) High dimensional stability

Specifications of 1.0mm/1.2mm/1.5mm EPDM rubber roofing waterproof membrane:

Material | EPDM Self-adhesive Waterproof Membrane |

Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

Thick | 1.2mm, 1.5mm, 2.0mm |

Type | Vulcanized & Weldable |

Pattern | Non-reinforced (homogeneous) |

Certificate | ISO9001/14001 |

Applications of 1.0mm/1.2mm/1.5mm EPDM rubber roofing waterproof membrane:

1.It is widely used in civil and industry construction.

2.The waterproof,dampproof of the roofs,basements,toilets etc;

3.And the waterproofing of subway,underground,bridges,car parking,tunnels,reserviors,pool etc.

4.SBS modified bitumen waterproof membrane is specially suitable to the building waterproofing in cold area and to the buildings of changeable constructions

5.APP specially suitable to areas of high temperature and of strong sunshine.

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Can a waterproofing membrane be used on flat roofs?

- Flat roofs can indeed benefit from the use of a waterproofing membrane. This method is widely recognized as one of the most effective and commonly used techniques for achieving waterproofing on flat roofs. The membrane itself is a thin material that is carefully applied to the roof's surface in order to prevent any water from seeping through. Typically constructed from durable and flexible substances like synthetic rubber or modified bitumen, the membrane is designed to withstand harsh weather conditions and offer long-lasting protection. By installing the membrane in overlapping layers, a continuous barrier is created that effectively seals the roof, preventing any water leakage into the building. Additionally, it is worth noting that waterproofing membranes can also provide insulation and energy efficiency advantages, which further contributes to their popularity in flat roof applications.

- Q: Can a waterproofing membrane be used for plaza decks?

- Plaza decks necessitate safeguarding against water infiltration to avoid harm to the underlying structure. This is where the application of a waterproofing membrane comes into play. These membranes are specifically designed to create a barrier, preventing water from permeating the deck and causing issues like leaks, deterioration, and structural damage. Typically composed of materials such as bitumen, rubber, or polyurethane, these membranes boast high resistance against water penetration. By incorporating a waterproofing membrane onto a plaza deck, it ensures the deck remains impervious to water, thereby preserving the integrity of the entire structure. Furthermore, these membranes offer additional advantages such as UV resistance, durability, and easy maintenance, rendering them an ideal solution for plaza decks.

- Q: Are waterproofing membranes resistant to chlorine exposure?

- Waterproofing membranes can vary in their resistance to chlorine exposure. Some membranes are specifically designed to be resistant to chlorine and are commonly used in applications where chlorine exposure is expected, such as pool decks or water treatment facilities. These membranes are typically made with materials like PVC or TPO that have inherent resistance to chlorine and can withstand prolonged exposure without significant degradation. However, it is important to note that not all waterproofing membranes are chlorine-resistant. Some membranes, particularly those made with materials like EPDM or bitumen, may not be as resistant to chlorine and may experience deterioration or damage when exposed to chlorine for extended periods. To ensure the longevity and effectiveness of a waterproofing membrane in a chlorine-rich environment, it is crucial to select a membrane that is specifically designed and tested for chlorine resistance. Consulting with a waterproofing professional or manufacturer can help determine the most suitable membrane for the specific chlorine exposure conditions.

- Q: Can a waterproofing membrane be covered or concealed by other finishes or materials?

- Yes, a waterproofing membrane can be covered or concealed by other finishes or materials. In fact, it is common practice to do so in construction projects. The purpose of a waterproofing membrane is to provide a barrier against water infiltration and protect the underlying structure. It is typically installed on surfaces such as roofs, foundations, or walls before other finishes or materials are applied. Covering the waterproofing membrane with other finishes or materials serves two main purposes. Firstly, it helps to enhance the aesthetics of the structure. Whether it is a roof, a bathroom, or a basement, concealing the waterproofing membrane allows for the installation of more visually appealing finishes like tiles, paints, or decorative elements. Secondly, covering the waterproofing membrane also provides an additional layer of protection. While the membrane itself is designed to be resistant to water, it can still be susceptible to damage from UV rays, foot traffic, or general wear and tear. By adding other finishes or materials on top, such as protective coatings, tiles, or concrete, the waterproofing membrane is shielded from potential damage, prolonging its lifespan and effectiveness. However, it is important to note that proper installation and compatibility between the waterproofing membrane and the covering materials are crucial. The covering materials should not compromise the integrity of the membrane or create any points of weakness. Additionally, any penetrations or joints in the covering materials must be meticulously sealed to maintain the waterproofing system's effectiveness. Therefore, while a waterproofing membrane can be covered or concealed by other finishes or materials, it is essential to follow manufacturer guidelines and consult with professionals to ensure that the overall waterproofing system remains intact and performs as intended.

- Q: Can a waterproofing membrane be used for shower installations?

- Indeed, for shower installations, it is advisable to employ a waterproofing membrane to avert water intrusion into the walls, floors, or any susceptible areas that may result in harm. A waterproofing membrane serves as a shield, prohibiting water infiltration into the nearby regions. This is especially crucial in showers where water is incessantly utilized and splattered. By implementing a waterproofing membrane, you guarantee that your shower area remains impervious to water and safeguarded against any possible water-related destruction.

- Q: Are waterproofing membranes resistant to hydraulic oils?

- No, waterproofing membranes are not typically resistant to hydraulic oils.

- Q: Can a waterproofing membrane be used on stadium seating areas?

- Yes, a waterproofing membrane can be used on stadium seating areas to provide protection against water damage and ensure the longevity of the seating structure.

- Q: Can a waterproofing membrane be used on tunnels with lighting systems?

- Yes, a waterproofing membrane can be used on tunnels with lighting systems. In fact, it is often necessary to use waterproofing membranes in tunnels to protect the structure from water infiltration. These membranes are designed to create a barrier that prevents water from seeping into the tunnel and causing damage. They are typically applied to the tunnel walls, floors, and ceilings and can be used in conjunction with lighting systems without any issues. The waterproofing membrane will not affect the functionality or safety of the lighting system and will help ensure that the tunnel remains watertight and protected from moisture-related issues.

- Q: How does a waterproofing membrane perform in areas with heavy foot traffic?

- A protective barrier against moisture and water penetration is the purpose of a waterproofing membrane in various applications. The performance of a waterproofing membrane is crucial in areas with heavy foot traffic. In such areas, the membrane's durability and strength become essential factors. A waterproofing membrane engineered specifically for heavy foot traffic can withstand the constant stress and pressure exerted by people walking, running, or using heavy equipment. Maintaining its integrity and preventing water or moisture from seeping through is one way a waterproofing membrane excels in areas with heavy foot traffic. It acts as a reliable shield, ensuring the underlying structure stays dry and protected. This is particularly important in spaces like balconies, terraces, or concrete walkways where water infiltration can cause structural damage, corrosion, or mold growth. Furthermore, a suitable waterproofing membrane for heavy foot traffic areas should possess excellent abrasion resistance. This means it can endure the friction and wear caused by frequent foot traffic without deteriorating or losing its waterproofing properties. The membrane should resist damage from shoes, heels, or other objects that may come into contact with its surface. Moreover, a waterproofing membrane for heavy foot traffic areas should be slip-resistant to guarantee the safety of individuals walking on it. It should provide sufficient traction and grip, even when wet, to prevent accidents or injuries. This is especially vital in spaces like swimming pool decks or commercial buildings where the risk of slipping is higher. In conclusion, a waterproofing membrane designed for heavy foot traffic areas performs by effectively sealing the surface, preventing water infiltration, and protecting the underlying structure. It should possess durability, strength, abrasion resistance, and slip resistance to ensure optimal performance and safety in areas subjected to heavy foot traffic.

- Q: Can waterproofing membranes be used in basements?

- Yes, waterproofing membranes can be used in basements. Waterproofing membranes are specifically designed to provide a barrier against water penetration and are commonly used in basements to prevent moisture and water seepage. These membranes are typically made of materials such as rubber, bitumen, or polyethylene, and are applied to the basement walls and floors to create a waterproof seal. By preventing water from entering the basement, these membranes help to protect the foundation, walls, and interior spaces from water damage, mold, and other moisture-related issues. Additionally, waterproofing membranes can also be used in combination with other waterproofing techniques such as drainage systems and sump pumps to provide comprehensive protection against water infiltration in basements.

Send your message to us

1.0mm/1.2mm/1.5mm EPDM rubber roofing waterproof membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 8000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords