EPDM Rubber Roofing Waterproof Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Waterproof Membrane

Introduction for EPDM Waterproof Membrane

This waterproof coiled material is of high elasticity with best performance among high polymer waterproof coiled material in the world.It is also the most typical one in the world.Waterproof coiled material made of ternary ethylene-propylene rubber of ‘CHEN SHENG’ brand is produced with the use of the most advanced continuous extrusion and vulcanization technology and related equipments which are specially designed for production of such product.It is good in compactness,without bubble and performance difference in length and breadth,performances reach or exceed the demands of GB18173.1-2012 standard.

Characteristics for EPDM Waterproof Membrane

1.Excellent anti-aging performance, service life can reach 50 years;

2.High elongation, high tensile strength, heat treatment size change small;

3.Plant root penetration resistance is good

4.Good low temperature flexibility

5.Application is convenient, overlapping is firm and reliable, no environmental pollution;

6. Resistance to chemical corrosion, can be applied to special places;

7.Maintenance is convenient, the cost is low

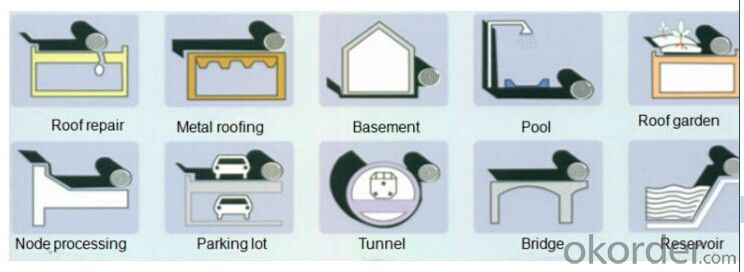

Application for EPDM Waterproof Membrane

1) Roofs, Basement, Toilet

2) Industrial and civil building waterproofing

3) Geo-synthetic liner for swimming pool, channels, irrigation system

4) Especially suit for projects with high requirements in durability, anti-corrosion and deformation

Specification for EPDM Waterproof Membrane

Item | Thick(mm) | Width | Length(m) | Color |

Spe | 1.0—2.0 | 1.2m/2m/3m/4m | 20 | Black |

Deviation | -1 +15 | --1 | Multicolor |

Technical Sheet for EPDM Waterproof Membrane

EPDM Waterproof Membrane ASTM Standard : D-7465 | ||||

Property | Test Method | Units | Mininum ASTM | |

D-7465 | ||||

Sl | Eng | |||

Specific Gravity | ASTM D-792 | gm/cc | 1.1 | 1.1 |

Unit Weight | ASTM D-751 | kg/m2 | 1.3 | 0.27 |

Thickness Type 1 | ASTM D-412 | mm(in) | 1.02 | 0.04 |

Tensile Strength. Die C | ASTM D-412 | Mpa(psi) | 9 | 1305 |

Ultimate Elongation,Die C | ASTM D-412 | % | 300 | 300 |

Tear Resistance,Die C | ASTM D-624 | Kn/m(lbf/in) | 26.27 | 150 |

Puncture Resistance | ASTM D-4833 | N(lbs) | 133 | 30 |

Shore A Durometer | ASTM D-2240 | 65-10 | 65-10 | |

Ozone Resistance | ASTM D-1149 | No Crack | No Crack | |

Multiaxial Elongation | ASTM D-5617 | % | 100 | 100 |

Heat Aging 28 days at 240 degrees | ASTM D-573 | |||

Tensile Strength, Die C | ASTM D-412 | MPa(psi) | 8.3 | 1205 |

Ultimate elongation, Die C | ASTM D-412 | % | 200 | 200 |

Tear Resistance, Die C | ASTM-624 | Kn/m(lbf/in) | 21.9 | 125 |

Accelerated Aging Xenon Arc | ASTM G-155/G-151 | Pass | Pass | |

Brittleness Point | ASTM D-2137 | -45 °C | -49 °C F | |

Water Absorption | ASTM D-471 | % | +8,-2 | +8,-2 |

Water Vapor Permeability, max | ASTM E-96 | Permils | 2.0 | 2.0 |

Linear Dimensional Change,max | ASTM-D-1204 | % | +/-1.0 | +/-1.0 |

Chronic Toxicity Screening | EPA/600/4-89/001 | Method 1000.0 | Pass | Pass |

FAQ:

Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q: Can a waterproofing membrane be used on precast nickel surfaces?

- Precast nickel surfaces can indeed benefit from the application of a waterproofing membrane. These membranes are specifically designed to create a barrier against moisture and thwart water infiltration. They can be effectively utilized on a variety of surfaces, such as concrete, metal, and even nickel. Nevertheless, it is crucial to ascertain that the waterproofing membrane is appropriate for use on nickel surfaces and is compatible with the particular type of precast nickel in question. To obtain guidance on the specific application and guarantee proper adhesion and effectiveness of the membrane on precast nickel surfaces, it is advisable to consult a professional waterproofing contractor or reach out to the manufacturer of the membrane.

- Q: Are waterproofing membranes suitable for high-traffic areas?

- Yes, waterproofing membranes are suitable for high-traffic areas. These membranes are designed to provide excellent durability and resistance against heavy foot traffic. They create a protective barrier that prevents water from seeping through and damaging the underlying structure. Additionally, waterproofing membranes can withstand the wear and tear caused by constant use, making them an ideal choice for areas with high foot traffic such as commercial spaces, parking garages, or outdoor walkways.

- Q: Can a waterproofing membrane be used for a basement floor slab?

- Yes, a waterproofing membrane can be used for a basement floor slab. A waterproofing membrane is designed to prevent water and moisture from seeping into the surface it is applied to. This makes it an ideal solution for protecting basement floor slabs from potential water damage. By installing a waterproofing membrane on the basement floor slab, you can create a barrier that effectively prevents water penetration, reducing the risk of water damage, mold growth, and structural issues. Additionally, a waterproofing membrane can also serve as a vapor barrier, preventing moisture from rising up through the slab and causing issues such as dampness or high humidity levels in the basement. Overall, using a waterproofing membrane for a basement floor slab is a smart choice to ensure the long-term durability and protection of the basement.

- Q: Can a waterproofing membrane be used on roofs?

- Yes, a waterproofing membrane can be used on roofs. Waterproofing membranes are often applied to roofs to provide a protective barrier against water penetration and ensure the roof remains watertight.

- Q: Can a waterproofing membrane be used on tunnels with vehicular traffic?

- Yes, a waterproofing membrane can be used on tunnels with vehicular traffic. Waterproofing membranes are designed to provide a barrier against water infiltration, protecting the structure from potential damage caused by moisture. In tunnels with vehicular traffic, water can seep through the concrete and cause corrosion, deterioration, and even compromise the structural integrity of the tunnel. By applying a waterproofing membrane, it creates a protective layer that prevents water from penetrating the tunnel walls, roof, and floor. This helps to extend the lifespan of the tunnel and ensures the safety of vehicles passing through. However, it is essential to select a waterproofing membrane specifically designed for heavy traffic conditions to withstand the constant load and wear. Additionally, proper installation and regular maintenance are crucial to ensure the effectiveness and longevity of the waterproofing system in tunnels with vehicular traffic.

- Q: Can a waterproofing membrane be used on terraces or patios?

- Yes, a waterproofing membrane can be used on terraces or patios. In fact, it is highly recommended to use a waterproofing membrane in these areas to prevent water damage and leakage. Terraces and patios are exposed to various weather conditions, including rain and snow, which can lead to moisture seeping into the underlying structure. A waterproofing membrane acts as a barrier, preventing water from penetrating the surface and protecting the integrity of the terrace or patio. It helps to extend the lifespan of the structure and prevents costly repairs in the long run. Additionally, using a waterproofing membrane also helps to create a more comfortable and usable space, as it eliminates the risk of water accumulation and potential slip hazards. Overall, investing in a high-quality waterproofing membrane is a wise decision for anyone looking to protect their terrace or patio from water damage.

- Q: Does a waterproofing membrane have any fire resistance properties?

- Generally, a waterproofing membrane does not possess any fire resistance properties. Its primary function is to create a barrier against water infiltration and safeguard the underlying structure from moisture-related harm. Conversely, fire resistance pertains to a material's capacity to endure fire or hinder the propagation of flames. Specialized fireproofing materials or coatings typically possess fire resistance properties and are specifically engineered to prevent fire spread and safeguard the structure during fire incidents. When choosing construction materials, it is crucial to consider both fire resistance and waterproofing prerequisites as they serve distinct purposes and may necessitate separate measures to ensure safety.

- Q: Can a waterproofing membrane be used for wastewater facilities?

- Indeed, wastewater facilities necessitate a strong safeguard against the potentially harmful and corrosive effects of wastewater. By employing a waterproofing membrane, the infiltration of water, which can result in structural harm, deterioration, and contamination of surrounding areas, can be effectively prevented. Waterproofing membranes act as a barrier, shielding the facility's walls, floors, and foundations from the intrusion of water and moisture. This serves to uphold the structure's integrity, prevent leaks, and guard against corrosion stemming from the presence of chemicals in wastewater. Furthermore, certain waterproofing membranes not only safeguard against water and chemical damage but also exhibit resistance to UV rays, high temperatures, and freeze-thaw cycles. This is particularly significant for wastewater facilities situated in regions characterized by extreme weather conditions. All in all, employing a waterproofing membrane in wastewater facilities is a dependable and efficient means of ensuring long-term protection against water damage, preserving the structural integrity, and augmenting the facility's durability.

- Q: Does a waterproofing membrane require any special considerations for installation in earthquake-prone areas?

- Installation of a waterproofing membrane in earthquake-prone areas necessitates special considerations. The ground in these regions is more susceptible to movement and shaking, which can greatly impact the integrity of the waterproofing system. Therefore, it is crucial to take additional precautions to ensure that the membrane is installed properly and capable of withstanding seismic activity. One important factor to consider is the choice of the waterproofing membrane itself. It is advisable to select a membrane that has been specifically designed and tested to endure seismic activity. These membranes are typically more flexible and possess higher tensile strength to accommodate ground movement during earthquakes. Moreover, the installation process should be executed with utmost care and attention to detail. The membrane should be securely anchored or fastened to the substrate using appropriate fasteners and adhesives. Reinforcement techniques, such as using reinforcing fabric or mesh, can also be employed to enhance the membrane's resistance to movement. Additionally, it is essential to ensure that all seams and joints in the membrane are adequately sealed and reinforced. Special attention should be given to areas that are more prone to movement, such as corners, edges, and penetrations. Utilizing compatible and high-quality sealants or adhesives will assist in maintaining the integrity of these vulnerable points. Regular inspections and maintenance are also critical in earthquake-prone areas. Periodically inspecting the membrane for any signs of damage, such as cracks or separations, allows for early detection and timely repairs. Additionally, it is vital to have a contingency plan in place to address any potential damage that may occur during an earthquake, including emergency repair procedures. In conclusion, the installation of a waterproofing membrane in earthquake-prone areas requires careful consideration and adherence to specific guidelines. By selecting an appropriate membrane, properly anchoring and reinforcing it, ensuring proper sealing of seams and joints, and conducting regular inspections, the waterproofing system can be better prepared to withstand earthquakes and provide long-lasting protection against water intrusion.

- Q: Are waterproofing membranes resistant to ponding water?

- Yes, waterproofing membranes are generally resistant to ponding water. Waterproofing membranes are designed to create a barrier that prevents water from seeping through and causing damage to the underlying structure. This includes standing or ponding water that may accumulate on the surface. However, it is important to note that the effectiveness of waterproofing membranes can vary depending on the specific product and installation technique used. It is recommended to consult with a professional to ensure the correct membrane is selected and installed properly to provide the desired level of resistance to ponding water.

Send your message to us

EPDM Rubber Roofing Waterproof Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords