Hdpe Geomembrane Machine

Hdpe Geomembrane Machine Related Searches

Geomembrane Hdpe Geomembrane In Hdpe Hdpe Geomembrana Geomembrana Hdpe Gse Hdpe Geomembrane Geomembran Hdpe Hdpe Geomembrane Installation Hdpe Membrane Hdpe Geomembrane Welding Hdpe Textured Geomembrane Wholesale Geomembrane Hdpe Hdpe Geomembrane Specifications Hdpe Geomembrane China Wholesale Hdpe Geomembrane Hdpe Geomembrane Sheet Hdpe Smooth Geomembrane Geomembrana De Hdpe Hdpe Geomembrane Factories Jual Geomembrane Hdpe Geomembrana In Hdpe Reinforced Hdpe Geomembrane Hdpe Geomembrane Price Hdpe Geomembrane Cost Hdpe Geomembrane Hs Code Solmax Geomembrane Hdpe Wholesale Hdpe Geomembrana Kolam Geomembrane Hdpe Solmax Hdpe Geomembrane Hdpe Applicazioni Geomembrane Hdpe Geomembrane ManufacturersHdpe Geomembrane Machine Supplier & Manufacturer from China

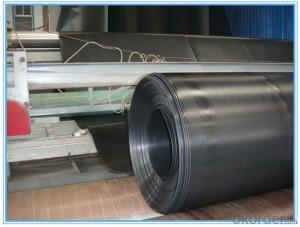

HDPE Geomembrane Machine is a specialized equipment designed for the production of high-density polyethylene (HDPE) geomembranes. These geomembranes are widely recognized for their exceptional impermeability and durability, making them ideal for various applications such as waste containment, water management, and environmental protection projects. The machine's advanced technology ensures the production of high-quality geomembranes that meet industry standards and requirements.The HDPE Geomembrane Machine is utilized in a broad range of scenarios, including landfill liners, pond liners, canal linings, and reservoir covers. Its versatility allows for the creation of geomembranes tailored to specific project needs, offering a cost-effective and efficient solution for various civil engineering and environmental applications. The product's robustness and resistance to chemicals, UV radiation, and temperature fluctuations make it a preferred choice for long-term projects where reliability is crucial.

Okorder.com stands as a prominent wholesale supplier of HDPE Geomembrane Machine, boasting a vast inventory that caters to the demands of different industries. With a commitment to quality and customer satisfaction, Okorder.com ensures that the HDPE Geomembrane Machine is available at competitive prices and with the support of a dedicated team to assist with any inquiries or requirements.

Hot Products