2016 widely perfect high quality PVC Foam Board

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

1. Brief Introduction

There are two kinds of PVC Sheet: PVC Foam Sheet and PVC Rigid sheet, and each of them could be cataloged by different producing processes.

They could be used in furniture making such as bathroom and kitchen cabinet or wall cladding , advertising field such as sign board, printing board, indusry field such as the cushion for the heavy machine, etc.

2. Application

1) Advertising Signs, billboards, displays, exhibition stands |

2) Screen printing, laser engraving |

3) Thermoformed parts |

4) Architecture, indoor and outdoor decoration |

5) Furniture, kitchen & bathroom cabinet |

6) Walls & partitions, wall cladding |

7) Ceiling boards |

8) Poolside furniture, swimming pool floor planking |

9) Chemical industry and laboratory equipment |

10) Apparatus, container & machine construction |

11) Interior scaleboard for boat & ship, vehicle, train |

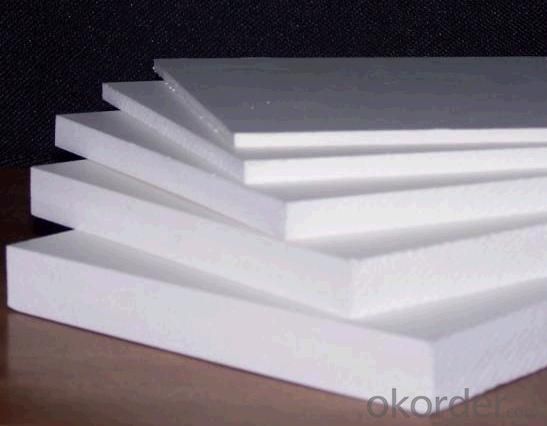

3. PVC Foam Board Feature:

1. waterproof, fire retardant, acid and alkali, moth, light, heat, noise, vibration characteristics;

2. equal and wood processing, and processing performance is far superior to wood;

3. wood, aluminum, composite board ideal alternative;

4. crust plate surface is very smooth, high hardness, not easy scratches, commonly used in the production of cabinets, furniture;

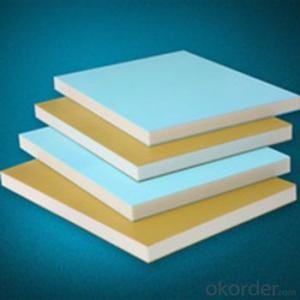

4. Pictures

- Q: The difference between resin and plastics

- Resin: refers to the raw materials, such as polyethylene resin, polypropylene resin, polyester resin, etc., but in general, plastic and resin two terms can be common. So, it can be said that plastic is resin, and resin is plastic. Thus, the resin is one of the raw materials of plastic, plastic is the finished product of resin. In other words, the resin is not formed and molded into plastic.

- Q: How do plastic raw materials trade? How big is the market?

- The transaction is mainly based on the traditional trading model and the Internet trading model 2.

- Q: How is plastic material made out?

- At present, resins are polymers that have not yet been blended with additives. Resin accounts for about 40% to 100% of the total weight of plastics. The basic properties of plastics depend mainly on the nature of the resin, but additives also play an important role.

- Q: Can PE material be used as food grade plastic?

- Yes, but the raw material suppliers have already divided the ingredients into food grade, and they will be used in non food occasions to contain substances harmful to the body

- Q: What is the essential difference between plastic raw materials and engineering plastics?

- Engineering plastics are a type of plastics, as well as general plastics.Like everyday things, what barrels, pots, plastic, etc?.

- Q: What are plastic materials extracted from?

- All kinds of plastics are gradually processed to produce various kinds of downstream products, including rubber, coating, finishing agent, artificial fiber, synthetic resin and so on.Resin usually refers to softening or melting range after heating. When softening, it tends to flow under external force. At normal temperature, it is solid, semi solid, and sometimes liquid organic polymer.

- Q: What is the difference between PP raw material and modified PP?

- Sort:(1) according to the characteristics of resin when heating and cooling, classification: 1. Thermosetting plastics, two, thermoplastics(2) according to the use of plastics classification: general plastic, engineering plastics, special plastic raw materialsModified PPThe concept of modified plastic PP, refers to the base of the general plastics and engineering plastics, after filling, blending and enhancement processing method of modification, improve the performance of flame retardant plastic products, strength, impact resistance, toughness.Classification: PP modified plastic products are mainly a variety of flame retardant resins, toughening resin, plastic alloy, functional masterbatch etc..

- Q: What machines and materials are needed for the manufacture of disposable plastic cups?

- Crusher is a large size of solid materials crushed to the required size of the machine. The crusher is composed of coarse crushing, fine crushing, pneumatic conveying and so on. It achieves the purpose of crushing in the form of high-speed impact. The use of wind power as a single powder eliminates traditional screening procedures.

- Q: What are the raw materials for producing plastic vest bags?

- The time required for plate making is usually about 5 days, and can be rented from a plate factory.Borrowed is printedPlastic vest bag printing is generally relatively simple, color is not complicated, simple and concise.And then there's the cutSealing and cutting are sealing and hollowing of printed material, and also the last step in forming waistcoat bags.Now, the advanced sealing machine is one step, without punching and hollowing.

- Q: What are the bulk density, size and moisture content of the general plastic material?

- Among them, the mass of the material has nothing to do with the particle size, but the larger particles have larger volume due to the presence of more voids between the particles. Small particles (powder) to the general packing is very tight, so the smaller bulk density.

Send your message to us

2016 widely perfect high quality PVC Foam Board

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches