Solmax Geomembrane Hdpe

Solmax Geomembrane Hdpe Related Searches

Solmax Hdpe Geomembrane Geomembrane Hdpe Hdpe Geomembrane Machine Geomembrane In Hdpe Geomembran Hdpe Geomembrana Hdpe Hdpe Geomembrana Gse Hdpe Geomembrane Wholesale Geomembrane Hdpe Hdpe Smooth Geomembrane Kolam Geomembrane Hdpe Hdpe Geomembrane Installation Wholesale Hdpe Geomembrane Hdpe Geomembrane China Jual Geomembrane Hdpe Hdpe Geomembrane Specifications Geomembrana Hdpe Sodimac Hdpe Geomembrane Sheet Hdpe Textured Geomembrane Reinforced Hdpe Geomembrane Hdpe Geomembrane Welding Geomembrana De Hdpe Hdpe Membrane Hdpe Geomembrane Price Daftar Harga Geomembrane Hdpe Hdpe Geomembrane Factories Geomembrana In Hdpe Hdpe Geomembrane Cost Hdpe Applicazioni Geomembrane Wholesale Hdpe GeomembranaSolmax Geomembrane Hdpe Supplier & Manufacturer from China

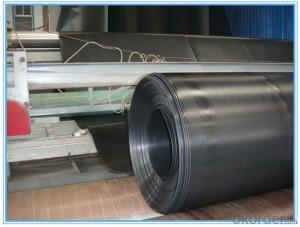

Solmax Geomembrane HDPE is a high-quality product made from high-density polyethylene, designed to provide excellent waterproofing and protection in various applications. This durable material is widely recognized for its ability to withstand harsh environmental conditions and resist chemical degradation, making it an ideal choice for a range of projects. Solmax Geomembrane HDPE is commonly used in civil engineering, landfill liners, water reservoirs, and other areas where reliable waterproofing and protection are essential. Its versatility and effectiveness have made it a popular choice among professionals in the industry.The Solmax Geomembrane HDPE is utilized in a variety of scenarios, including but not limited to, environmental protection projects, construction sites, and agricultural applications. Its impermeable nature and robust construction make it a reliable barrier against water and other contaminants, ensuring the integrity of the underlying structures. This product is also praised for its resistance to UV radiation, which allows it to maintain its performance even when exposed to sunlight for extended periods. The Solmax Geomembrane HDPE's adaptability to different terrains and its ability to be easily cut and shaped according to specific project requirements further enhance its utility.

Okorder.com is a reputable wholesale supplier of Solmax Geomembrane HDPE, boasting a large inventory that caters to the needs of various industries. As a trusted source for this product, Okorder.com ensures that customers receive top-quality materials at competitive prices. Their extensive stock allows for quick fulfillment of orders, making them an ideal choice for businesses and projects that require a reliable and consistent supply of Solmax Geomembrane HDPE. By partnering with Okorder.com, customers can be confident in the quality and availability of this essential product, ensuring the success of their projects.

Hot Products