4*8 foam sheets pvc celuka board display panel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

About us:

We are packaging foam board manufacturer, packaging foam board is becoming the substitution of wood in many fields such as AD and Decoration. We have our own factory, transportation system, overseas warehouse, industrial park.As a professional manufacturer. It made through foaming and pressing into shape with additives. The main material is PVC. So it covers not only features of woodplast, but also very light and can be printed, engraved easily.

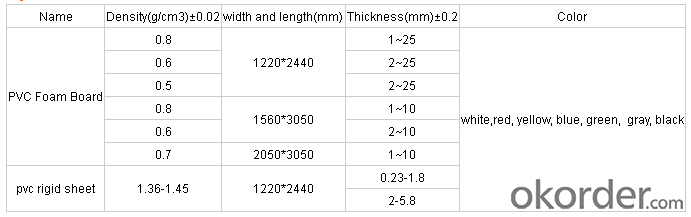

Product Specification

Regular size: 1220*2440mm, 1560*3050mm, 2050*3050mm

Thickness:1-33mm

Density:0.43- 0.9mm

Product Features

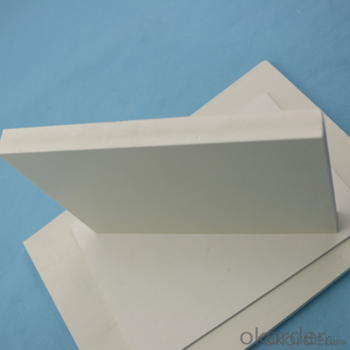

1.Waterproof, fireproof retardant, moistureproof, anticorrosive, Weather resistant, moth-proofing, anti cracking, anti UV.

2.Less warping, stand wear and tear, acid and alkali resistance, easy coloring, no glue and paint

3.Can be nailed, drilled, shaved, chiseled, riveted, With wood properties and better than wood, color diversity

4. Safety and environmental protection, formaldehyde-free

5. Easy to install, easy to clean, easy to maintain

Product Uses

1 mm- 5 mm: suitable for advertising supplies, electronic instrument, packaging

15 mm -20 mm: suitable for furniture

10 mm -20 mm: suitable for bath cabinet, cabinets

5 mm- 20 mm: exhibition board, indoor and outdoor decorative plate (different customers have different requirements)

3 mm coated :bus interior ceiling

Product Application

(1)Advertising: exhibition display, digital printing, silk screen printing, computer lettering, sign board, light box, etc.

(2)Construction: office and bathroom cabinets, inner and outer decorate panel, commercial decorating shelf, room separating

(3)Transportation: steamboat, airplane, bus, train carriage, roof and carriage inner layer and other industry.

FAQ

Q: What's the PVC Foam Sheet Processing performance?

A: 1, plastic coating, membrance-stuck and printing

2, with the usual equipment and tools, it can be processed again.

3, welding and bonding

4, cutting and sawing

5, bending when heated-up, thermal forming

6, hole-drilling, Channeling and die cutting

Q: How many colors you have?

A: We have more than 100 existed colors. We can send the color swatch if you leave your message. Also customized colors are acceptable.

Pictures

- Q: What kind of material is the raw material of plastic pipes?

- The raw material of plastic pipe is mainly based on the plastic tube type, type, polyethylene plastic pipe (PE) is the raw material of ethylene, polyvinyl chloride (PVC) material is polyvinyl chloride, polypropylene pipe (PB) is the raw material propylene.

- Q: What is the difference between EPS plastic particles and PS? What materials are represented?

- PS does not have no foaming agent. It is divided into GPPS (ordinary type) and HIPS (impact type). It is used for injection molding, extrusion, television, telephone shell, cup and so on.The main ingredients are polystyrene.

- Q: What are the raw materials of plastics made of?

- Synthetic resin refers to coal, petroleum, natural gas, calcium carbide and some agricultural products as the main raw material, the low molecular weight compounds prepared firstly has certain synthetic conditions (monomer), and then through chemical and physical methods for the synthesis of high molecular compound. The characteristics of this kind of compounds similar to natural resin (such as rosin, shellac, amber, etc.), but the performance and more superior than the natural resin.

- Q: What kinds of plastic properties can be divided into thermal properties?

- A. thermoplastic(a) polyvinyl chloride (PVC)Is the most widely used plastic varieties. Polyvinyl chloride resin is made from poly (vinyl chloride) monomer. According to the amount of plasticizer, it is divided into hard PVC and soft PVC. The former adds 30~70 phr of plasticizer <5 in 100 heavy resins, and the latter adds plasticizers.Physical properties: the relative density of hard PVC is 1.35 to 1.60, which is 1 / 5 of carbon steel; the relative density of soft PVC is 1.2 ~ 1.4.The water absorption rate of hard PVC is very low. The water absorption rate in long-term immersion in water is <0.5%; the soaking water is 24h, and the water absorption is 0.05%. The permeability of PVC is very low.The glass state temperature of PVC is 80~85 DEG C, the viscosity is 180 DEG C, the decomposition temperature is 240~260 DEG C (including stabilizer), and the brittleness temperature is -50 ~ -60 DEG C.The recommended temperature range of hard PVC is, in principle, maintained in terms of brittleness and glass temperature. If it is used above 50 degrees, necessary measures should be taken.The pure PVC, without stabilizers, begins to decompose at 150 C, releases hydrogen chloride, and further accelerates its decomposition. It decomposes faster than 180 DEG C. The polyvinyl chloride with the stabilizer decomposes the temperature to 240~260 degrees centigrade, but breaks down hydrogen chloride if used for 220 years. The material changes from dark grey to yellow brown, or even black. Therefore, in welding, we should try to avoid this phenomenon, the linear expansion coefficient of hard polyvinyl chloride is (5~6) X10-5 / DEG, 5-6 times larger than carbon steel. Therefore, when installing polyvinyl chloride pipes, expansion joints or bracing shall be installed to prevent deformation. When polyvinyl chloride is used as lining or bonding with other materials, the peeling phenomenon may be considered when heated.

- Q: Will plastic raw materials (such as PET, PP, etc.) be made of non-woven fabrics, will certainly contain BPA?

- BPA doesn't come out of thin air. PC uses BPA as raw material, so it comes with a little bit. Most plastics do not contain bpa. If you need to verify, you can test it and then ask the supplier to verify it. The electronic industry has done so, every level to find upstream suppliers signed a certificate of protection. We should ensure that mobile phone materials do not contain BPA, plasticizers and more than 150 substances.

- Q: ABS plastic storage conditions

- Plastic materials generally react with light and oxygen for a long time to become yellow and brittle

- Q: Does anyone know what kind of plastic material PP-M40 is?

- High gloss PP has high gloss, high fluidity, heat resistance, medium impact toughness and fine processability. The utility model is suitable for making household appliances (rice cookers, vacuum cleaners, electric irons, etc.), office equipment, instruments and meters, beauty equipment, etc..

- Q: What are the criteria for the classification of plastic materials at injection molding and extrusion?

- The new plastic materials, manufacturers have set by type of good applicability, according to the model can be used, but not to say that the plastic extrusion grade no injection molding, injection molding grade plastic extrusion processing can not, some engineers to use the material properties, will use the technological method for solving extrusion or injection molding grade between the influence.

- Q: Aluminum Alloy door corner with what plastic raw materials do?

- Nylon two times, generally eight thousand and one hundred tons of good, I do the mold, and my customers are using this material

- Q: What do you mean by grade 1, class two or class three in plastic?

- A material refers to the raw materials used for scrap without landing, or called under the angle of material, some material floolwing, plastic head material, quality is also quite good, is not used, in the process of new material processing, while the remaining small angle, or the quality of the raw materials. The particles which are made of the wool have better transparency and can be compared with the new material, so they are grade materials or superfine materials.

Send your message to us

4*8 foam sheets pvc celuka board display panel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords