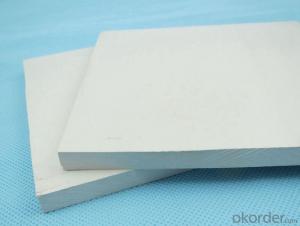

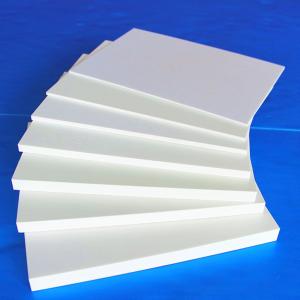

4x8 PVC Forex Sheet Sintra Celuka Crust High Density White PVC Foam Board

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

PVC foam board is made from polyvinyl chloride, with flat plate surface; it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof, anticorrosive, metabolic and recyclable, moisture resistant, lightweight.

Features

(1)Water durable: Closed-cell foam, non-water-absorbing, moisture-proof.

(2) Rot resistant: Seawater, oil, acid and alkali durable; antibacterial, safe, odorless and non-polluting.

(3) Easy processing: Continuous; easy hot-press shaping, casting, gluing and joining.

(4) Shockproof :Good flexibility and anti-hardening; excellent shockproof and cushion capability.

(5) Heat preservation: Excellent heat insulation, anti-cold, non-frosting and insulation enduring capabilities.

(6) Sound insulation: Closed-cell foam, good sound insulation capability.

(7) Application: Widely used in puzzles, resting cushions, children's toys , medium and shoes material ,compound floorboard ,craftwork decoration sand ,shoe material , packing lining ,curtain wall and so on

Applications

1. Building outdoor wall board, indoor decoration board, partition board in office and house.

2. Screen printing, flat solvent printing, engraving, billboard and exhibition display.

3. Chemical anti corrosion project, special cold project, environmental protection.

4. Sanitarywares, kitchen cabinet, washroom cabinet.

5.Advertisment

6.Contruction

- Q: for our last day of term at uni, we are hoping to make a big water slide down our corridor, (about 12m x 2m) the sheet would have to be waterproof as it will be covered in either washing up liquid or baby oil (probably no actual water) at the minute our cheapest material is looking like bin bags and duct tape, but does anyone know of a cheap, plastic like material we could use instead, to avoid the inevitable leaks from the joins?

- Go to any builders yard and you can get a massive roll of 1000g plastic which is generally used as DPC (damp proof course) under the floors of buildings. Cost...long time since I bought it about ?30/ or you can buy any length of it you like, off the roll.

- Q: Are plastic sheets transparent to radio waves?

- No, plastic sheets are not transparent to radio waves.

- Q: How are plastic sheets manufactured?

- Plastic sheets are typically manufactured through a process called extrusion, where plastic pellets or granules are melted and then forced through a die to form a continuous sheet. The molten plastic is cooled and solidified as it passes through rollers, resulting in a flat and uniform plastic sheet.

- Q: Are plastic sheets resistant to staining?

- Yes, plastic sheets are generally resistant to staining due to their non-porous nature and smooth surface, which makes them easy to clean and maintain.

- Q: or what? the application for college asks for photos in a loose leaf standard-sized portfolio, i'm assuming this means in a 3-ring binder and with clear plastic sheets that i buy separate. or am i wrong? this is important : )

- a loose leaf binder is a three ring binder that has 3 rings that snap open and closed and you fill it with loose leaf paper. the actuality that metallic rings are unique ability you're able to purchase a binder with metallic, and not plastic rings...it is clever simply by fact the plastic ones are inexpensive and frequently wreck.

- Q: i am working on an art project and I am wondering if there is a crafty type way for me to transfer the typed text from one sheet of paper to another (like to lift the ink off the paper somehow). I am not concerned about the words being recognizable or readable, I just like the aesthetic of words that don't necessarily mean anything mixed with pictures. thanks!

- It's called a photocopier. Photocopy the page onto a sheet of transparent plastic. Then lay the plastic over the new sheet where you want the letters to appear. If you don't want the plastic, the process is trickier. It still can be done. Photocopy the page onto plastic as before. Then lay the photocopied plastic sheet reversed on the photocopying glass. Copy onto a piece of paper. The result will be a sheet of paper with the letters reversed. Since photocopiers use toner that is baked onto the page, you need to take the sheet with reverse lettering and iron (using a hot iron) the reversed lettering onto the page you want it to appear. Since you are reversing a reversal, the result will be correct left-to-right. It might take several tries to get the technique down right, but it is do-able. Whether it is worth it, you'll have to determine.

- Q: Can plastic sheets be used for interior design applications?

- Yes, plastic sheets can be used for interior design applications. Plastic sheets offer a wide range of design possibilities, as they come in various colors, patterns, and textures. They can be used for wall cladding, ceiling panels, room dividers, furniture, and other decorative elements. Additionally, plastic sheets are durable, easy to clean, and cost-effective, making them a popular choice for interior designers.

- Q: Why is there a gap of 1 mm between the plastic mould, A plate and B plate? Is there a gap between the die and the die?

- The mold is certainly no gap between, otherwise there will be flash (Pi Feng), leaving a gap of 1 mm between A plate and B plate is to die between better together, which can avoid A, B plate and mold tight, not tight.

- Q: Whenever I have sex, females ended u ejaculating... and its a lot! It obviously ruins my bed and causes unpleasantness after sex. I think I need to put on something to guard my mattress and bed sheet. How about plastic sheets? Where can I get them? Do you have any other suggestions?

- they actually sell them at walmart! they're not expensive at all, they sell them for people with allergies and people who have problems wetting the bed... they're in the same section as the rest of the sheets. they have the kind that can wash off with a wash cloth or the kind that have a cloth top like a regular sheet that is plastic underneath so it's not such a plasticy feeling on top when you sleep on it that you just throw in the washer when you need to wash it...

- Q: How do plastic sheets handle adhesive bonding?

- Plastic sheets handle adhesive bonding quite well, as they provide a smooth and non-porous surface for the adhesive to adhere to. However, it is important to select the appropriate adhesive that is compatible with the type of plastic being used to ensure a strong and durable bond.

Send your message to us

4x8 PVC Forex Sheet Sintra Celuka Crust High Density White PVC Foam Board

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords