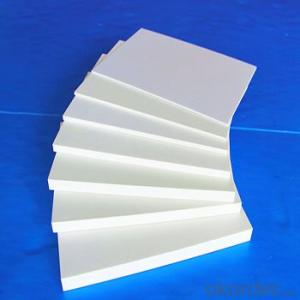

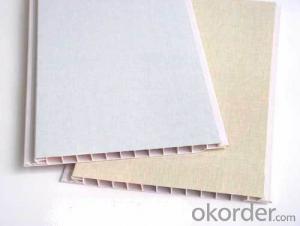

Light Weight PVC Foam Board PVC Celuka Board Plastic Forex Sheet

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Brief Introduction

There are two kinds of PVC Sheet: PVC Foam Sheet and PVC Rigid sheet, and each of them could be cataloged by different producing processes.

They could be used in furniture making such as bathroom and kitchen cabinet or wall cladding , advertising field such as sign board, printing board, indusry field such as the cushion for the heavy machine, etc.

2. Application

1) Advertising Signs, billboards, displays, exhibition stands |

2) Screen printing, laser engraving |

3) Thermoformed parts |

4) Architecture, indoor and outdoor decoration |

5) Furniture, kitchen & bathroom cabinet |

6) Walls & partitions, wall cladding |

7) Ceiling boards |

8) Poolside furniture, swimming pool floor planking |

9) Chemical industry and laboratory equipment |

10) Apparatus, container & machine construction |

11) Interior scaleboard for boat & ship, vehicle, train |

3. Features

1) UVprotected, Antichemical corrosion

2) Fire retardant and it can automatically extinguish by itself

3) Sound insulation, sound absorption, heat insulation and heat preservation

4) Moistureresistant, mildew proof, water repellent and shock proof

5) Nondeformation, agingresistant, color fastness for a very long time through particular formula

6) Light weight, easy and convenient for storage, transportation and using

7) It has a smooth and hard surface and is suitable for painting

4. Pictures

- Q: Can plastic sheets be used for mold-making in manufacturing?

- Yes, plastic sheets can be used for mold-making in manufacturing. They are commonly used for creating molds in various manufacturing processes, such as vacuum forming or thermoforming, where a heated plastic sheet is shaped around a mold to create a desired product. Additionally, plastic sheets can also be used to create prototype molds for casting or casting resin applications.

- Q: I want to build a table and for the top i would like it to be a sheet of cloudy or frosted plexiglass or perhaps acrylic about 3' x 6', so light can shine through it. Which is cheaper? Where can i find them?

- You could google translucent plastic sheet and see if you get any products of interest. Alternately, you could purchase your plastic sheet and have someone hit it lightly with a sandblaster. If you create an artistic pattern or shield to go over part of the plastic, you'll get a picture where the clear plastic is surrounded by cloudy plastic. Good luck!

- Q: Nascar: true paint or plastic sheet?

- Nascar Vinyl Wrap

- Q: Can plastic sheets be used for insulation?

- Yes, plastic sheets can be used for insulation.

- Q: Pink fiberglass insulation comes either faced or unfaced. On DIY shows on TV, I almost always see people using unfaced insulation and putting a sheet of plastic visqueen over the studs, rather than using faced insulation and not needing visqueen. Which method is better?

- This Site Might Help You. RE: When insulating walls, which is better -- plastic sheeting or built-in vapor barrier? Pink fiberglass insulation comes either faced or unfaced. On DIY shows on TV, I almost always see people using unfaced insulation and putting a sheet of plastic visqueen over the studs, rather than using faced insulation and not needing visqueen. Which method is better?

- Q: considering using sturdy plastic poster-board or something similar to cover different gaps in the under-body to smooth it out and hopefully improve fuel efficiency. ideas on what to use wanted.I have a small coupe, i am not looking to pay to lower my car. i would like ideas to help me patch up the underbody please. cheap fix to try and save money; very handy and open to strange ideas. all help welcome;please helpful thoughts only thanks

- well this is what i would do, don't lower the car just add a new front bumper or as you want to be cheap just add a front bumper wrap or you may hear it called a front wing / air dam. alot of the time the air dam will come primed and you need someone just to paint it (sometimes comes black) All you need is a drill and a few auto body clips ( and bolts that fit the clips) One of my buddies just added a air dam which came black (45 plus shipping) after that he just need to add bolts.

- Q: Are plastic sheets resistant to chemicals in swimming pool environments?

- Yes, plastic sheets are generally resistant to chemicals in swimming pool environments. They are commonly made from materials such as polyethylene or PVC, which have excellent chemical resistance properties. These plastics can withstand exposure to chlorine, bromine, and other pool chemicals without significantly degrading or corroding. However, it is important to note that prolonged exposure to certain harsh chemicals or extreme temperatures may still cause some deterioration or discoloration over time.

- Q: Can plastic sheets be used for outdoor signs?

- Yes, plastic sheets can be used for outdoor signs. They are often made from durable materials such as acrylic or polycarbonate, which are weather-resistant and can withstand outdoor elements like rain, sunlight, and wind. Plastic sheets are lightweight, easy to handle, and can be easily customized with graphics and text. Additionally, they are cost-effective compared to other sign materials, making them a popular choice for outdoor signage.

- Q: Are plastic sheets UV-resistant?

- Yes, plastic sheets can be UV-resistant.

- Q: Can plastic sheets be used for greenhouse roofing?

- Yes, plastic sheets can be used for greenhouse roofing. Plastic sheets are a popular and cost-effective option for greenhouse roofing as they allow sunlight to pass through, providing the necessary light and warmth for plant growth. They are also lightweight, easy to install, and offer good insulation properties to retain heat inside the greenhouse. However, the type and quality of the plastic should be considered to ensure long-term durability and proper light transmission.

Send your message to us

Light Weight PVC Foam Board PVC Celuka Board Plastic Forex Sheet

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords