Plastic Sheets - PVC Caluka Foam Board PVC Forex Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 mm

- Supply Capability:

- 10000 mm/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Product Introduction

PVC foam board is made from polyviny chloride, with flat plate surface, it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof,anticorrosive,ametabolic and recyclable,moisture resistant,lightweight.

PVC foam is a special form of PVC, but the base material is still manufactured using the same process used to create all PVC products. PVC falls into the category of thermoplastic resins. It is made primarily from a combination of chlorine and carbon. The carbon in the plastic is obtained from oil and gas, but this plastic actually requires less oil and gas than many other types of plastic products.

2. Product Specification

Regular size: 1220*2440mm,1560*3050mm,2050*3050mm

Thickness:1-33mm

Density:0.35-0.9

3. Product Features

(1) Light weight, waterproof, fire retardant and self-extinguishing

(2) Sound insulation, heat insulation, noise absorption, heat preservation and anti-corrosion.

(3) Tough, rigid with a high impact strength, not easy to age and can keep its color for long

(4)Easy to clean and maintain.

(5)Envioronmental-firendly green and lead-free.

4. Product Application

(1) Advertising: exhibition display, digital printing, silk screen printing, computer lettering,sign board, light box,etc.

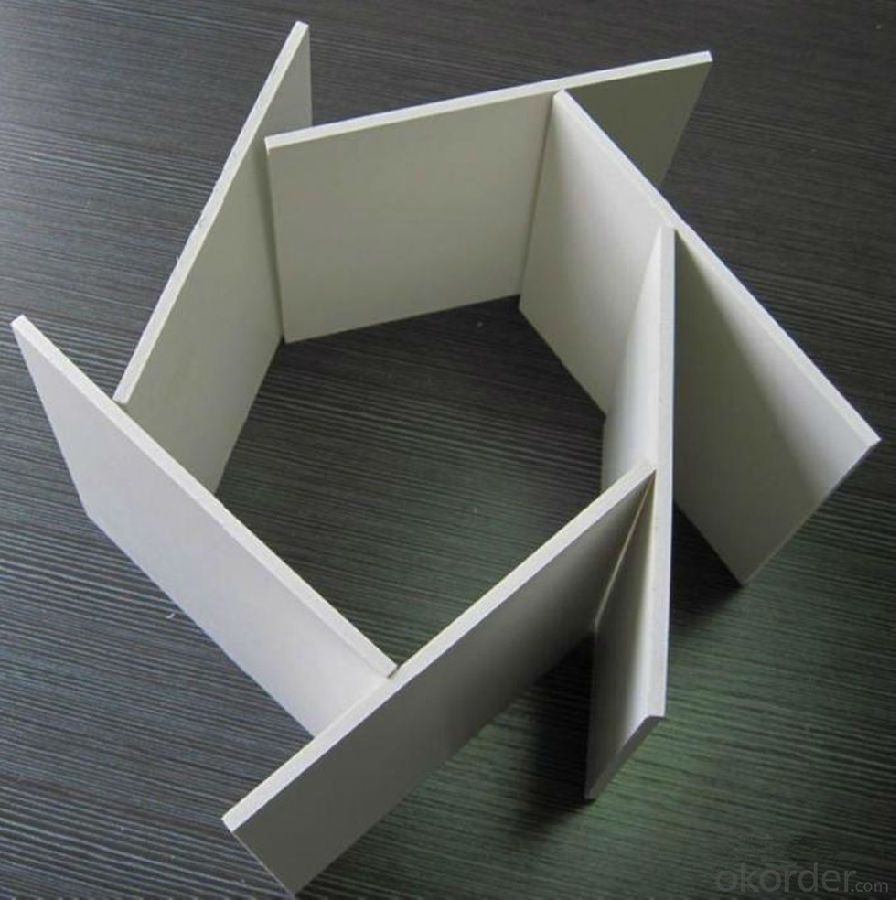

(2) Construction: office and bathroom cabinets, inner and outer decorate panel,commercial decorating shelf, room separating

(3) Transportation: steamboat, airplane, bus, train carriage, roof and carriage inner layerand other industry.

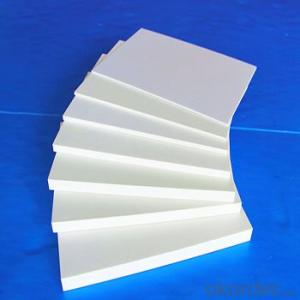

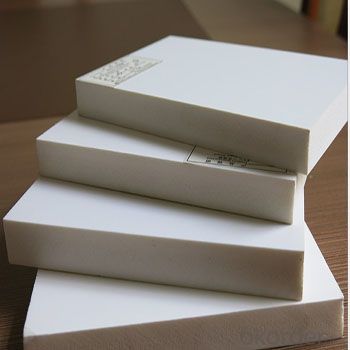

5.Pictures of PVC Foam Board

6.Factory Pictures

7.FAQ

Q: Are your samples free of charge?

A: Yes,Samples are arranged upon request within 3 workdays

Q: Can we visit your company to inspect products before delivery?

A: You are welcome to visit our company to inspect us and our products.

- Q: Is there a glue that can seal/bond 2 thin (about 30 microns or less) sheets of plastic together, the same EXACT way that they would seal/bond if the same 2 sheets were heat sealed? (kinda like those food vacuum sealers)

- I have the same problem. I have tried melting some of the plastic and pressing it between the sheets. This only seemed to melts the sheets also. I have used Gorrilla Glue, Silicone, Super Glue and Epoxy and have had no luck. Double sided tap sorta worked but it takes a ton of it. So far the best thing I have found is just using Duct tape. It's ugly and falls off in the heat of the summer but does work temporarily. I will definitely buy an iron and try that. That seems like the best idea yet. I did visit an adhessive manufacturers website and they say there is nothing invented yet that bonds sheeting together permanently. I find this hard to believe. I have used a vacumme sealer for freezer bags and it works wonderfully on really thin plastic but the thicker sheeting I need and it has no affect on that.

- Q: Kitchen roof plastic buckle how to dismantle?

- The plastic material for the kitchen ceiling, because such materials need to use professional tools in the demolition, but accidentally damage the original structure or not in the decoration into the installation problems, therefore need to remove the professional staff of the demolition work, so to ensure the smooth completion of the decoration again.

- Q: Do plastic sheets come with warranties?

- Yes, plastic sheets often come with warranties, which may vary depending on the manufacturer and the specific product.

- Q: Can plastic sheets be transparent?

- Yes, plastic sheets can be transparent.

- Q: Can plastic sheets be printed on?

- Yes, plastic sheets can be printed on.

- Q: Can plastic sheets be used for insulation in refrigeration?

- Yes, plastic sheets can be used for insulation in refrigeration. They are commonly used as a vapor barrier and to provide thermal insulation in refrigeration systems.

- Q: Can plastic sheets be used as barriers?

- Yes, plastic sheets can be used as barriers. They are commonly used in various applications such as construction sites, hospitals, and food establishments to create partitions, protect against dust or contaminants, and provide a physical barrier for safety purposes.

- Q: Can I use all these plastics sheets and duct tape I bought after 9/11 to protec me from e. bola?

- Exemplary discourse my cohort

- Q: Can plastic sheets be used for packaging materials?

- Yes, plastic sheets can be used as packaging materials. They are commonly used in various industries for packaging products due to their durability, flexibility, and ability to protect against moisture and contamination. Plastic sheets can be molded or formed into different shapes and sizes to accommodate various packaging needs.

- Q: Do plastic sheets come in different colors?

- Yes, plastic sheets come in a variety of colors.

Send your message to us

Plastic Sheets - PVC Caluka Foam Board PVC Forex Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 mm

- Supply Capability:

- 10000 mm/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords