Oil Resistant Irradiation Cross-linkable Low Smoke Zero Halogen Flame Retardant Polyolefin Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

locomotive cable compound:

(1) competitive price

(2) 30 years of experience

(3) stable quality

(4) customized product

Locomotive Cable Compound:

1. Applications and cable specifications:

Applied to the locomotive cables which voltage is less than 3KV and temperature is 125°C.And the cable is used in the no mineral oil and no fuel oil environment.

2. Description:

Irradiation cross-linkable, low smoke halogen free and flame retardant POE compound for locomotive cables, based on special high oil resistant POE resin, is produced and pelletized by special technology with adding special stabilizing agent, modifier, halogen free flame retardant, cross-linking agent, antioxidant and other special additives. It meets the locomotive cable requirements of high temperature resistant and oil resistant.

3. Processing:

Irradiated dosage:12-15 megarad

The compound can be processed with conventional extruders, and the normal PVC screw with a minimum 20:1 L/D. It is better if use low compression ratio screw.

The following temperature(°C) profile of extruder is recommended:

| Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die |

| temperature °C | 130 | 145 | 150 | 150 | 145 | 145 |

4. Storage and transport:

Packing: 25kg/bag, PE membrane inside bag and craft outside bag.

Avoiding in direct sunlight and weathering.

Storage place should be clean, cool, dry and ventilated.

5. Properties:

| Item | Unit | Standard Value ( after irradiation cross-linked) | ||

| JFDW04 | JFDW05 | JFDW06 | ||

| Tensile Strength | ≥Mpa | 9 | 9 | 9 |

| Elongation at Break | ≥% | 125 | 125 | 125 |

| Thermal Aging | Condition °C×h | 158×168 | 158×168 | 158×168 |

| TS/EB retention | 80 | 80 | 80 | |

| ≥ % | 60 | 60 | 60 | |

| High temperature pressure test | Temp.°C | — | 125 | 125 |

| ≤ % | — | 50 | 50 | |

| Oil resistant | Type | — | 20# machine oil | 20# machine oil |

| condition°C×h | — | 100×70 | 100×70 | |

| Variation on Tensile Strength | ≤ % | — | -50 | -50 |

| Variation on Elongation at Break | ≤ % | — | -50 | -50 |

| Oil resistant | Type | — | — | 0# diesel oil |

| condition °C×h | — | — | 70×168 | |

| Variation on Tensile Strength | ≤ % | — | — | -55 |

| Variation on Elongation at Break | ≤ % | — | — | -55 |

| Impact Brittleness Temperature | ≤ °C | -40 | -40 | -40 |

| Volume Resistivity, at 20°C | ≥Ω.m | 1.0×1012 | 1.0×1012 | 1.0×1012 |

| Oxygen Index | ≥ | 30 | 30 | 30 |

| Smoke Density Flaming | ≤ | 100 | 100 | 100 |

| Non flaming | ≤ | 200 | 200 | 200 |

| Acidity of gases evolved (pH) | ≥ | 4.3 | 4.3 | 4.3 |

| Conductivity of gases evolved | ≤μs/mm | 10 | 10 | 10 |

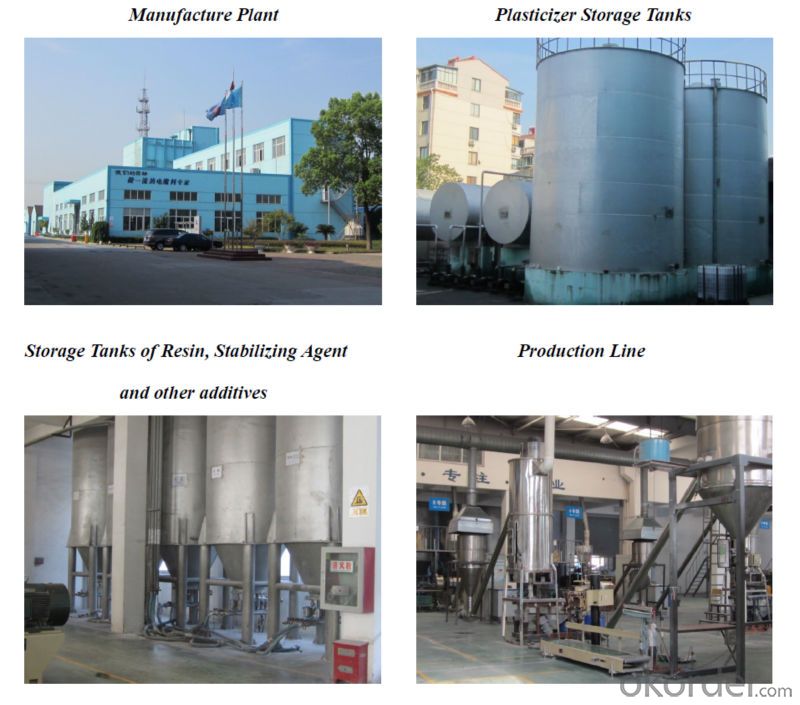

6. Company

- Q: I'd like to know what PP plastic material is PP plastic raw materials cleaning can not use ultrasonic cleaning machine to wash it?

- PP plastic raw material is a thermoplastic resin. Its density is small, strength, stiffness, hardness, heat resistance are better than low-pressure polyethylene, can be used in about 100 degrees. With good electrical properties and high frequency insulation, free of moisture, but brittle at low temperatures, wear and aging, suitable for making general mechanical parts, corrosion resistant parts and insulation parts.

- Q: What are the POE plastic raw materials?

- POE classification of plastics raw materials:Plasticizing properties: Thermoplastics and thermosetting plastics.Divided by use: General Plastics and engineering plastics.

- Q: What is the hardness of PAEK+30%GF plastic material?

- Mohs hardness is mainly used in mineral classification. The Mohs scale from I to 10. the scratch resistance increasing (such as talc Mohs hardness is I, the diamond is 10), namely each scale corresponding to the Mohs material can be scraped traces in the previous stage of material. According to the Mohs hardness can determine the scratch resistance between contact with objects in the use of Engineering plastics.Engineering plastics Mohs hardness is between 2 and 3.

- Q: What material is plastic bag made of?

- Polyethylene (Polyethylene, PE), referred to as PE. It is a high molecular organic compound which is made up of ethylene. Polyethylene is recognized as the best food for contact with food in the world. Non-toxic, tasteless, odorless, in line with food packaging hygiene standards. Polyethylene film, light and transparent, with moisture-proof, anti - oxygen, acid, alkali, air tightness, heat sealing and other outstanding performance. Known as "plastic flowers" laudatory title. It is the most important and most important material in plastic packaging and printing.

- Q: Is the tableware made of PP raw material the best of those plastic tableware?

- Plastic tableware with melamine resin powder heat pressing, also known as melamine tableware melamine tableware.PP plastic is polypropylene, non-toxic, can make pots, buckets and other kitchen utensils.

- Q: What is the material of plastic flat screen?

- Widely used in aquaculture, poultry farming, sericulture, civil construction, aquaculture, garden care, keep the field of railway and highway subgrade reinforcement, etc., can also be used for mattress, sofa cushion, car cushion, which is characterized by low cost, long service life.Material: high density low pressure polyethylene (PE), polypropylene (PP), ABS plastic particles.Colors: black, white, orchid, green, yellow, red and so on.

- Q: PVC what chemicals do you need for plastic surface treatment?

- Different processing methods are often required for different materials.

- Q: PP plastic stool surface with those raw materials, what is the ratio?

- PP is crystalline polymer. PP is the most common plastic, and the density is only 0.91g/cm3 (smaller than water).

- Q: What are the heavy bags in the plastic material?

- Plastic raw materials in the heavy bag refers to high pressure polyethylene (LDPE) is a kind of special, for the production of plastic packaging bags, the plastic bags bearing force and pulling force are high, and have a high degree of transparency, plastic raw materials sales is often called the heavy bag material, melting point to: 0.3

- Q: What do you mean by grade 1, class two or class three in plastic?

- Three grade material refers to the raw material has been used two times or more times, the processing of particles, and its elasticity, toughness and other aspects are not very good.

Send your message to us

Oil Resistant Irradiation Cross-linkable Low Smoke Zero Halogen Flame Retardant Polyolefin Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches