Waste Plastic PET Bottle Recycling Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 20 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

waste plastic PET bottle recycling line

1,capacity:300-2000kg/h

2.,CE,ISO

3.Omron tranducer

4.OEM

waste plastic PET bottle recycling line

A.Technical Parameters

1. Belt conveyer

Transporter with frequency control, to adjust speed to requirements of line.

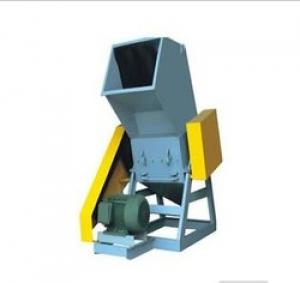

2. Crusher

This crusher is designed for wet crushing. It is equipped with eight rotating and four stationery knives. Crusher is supplied with standard grid size of 16mm and spare grid of 18mm. Input capacity is 1, 000kg/h can be increased with 18mm grid size.

3. Screw conveyer

Transport flakes from crusher.

4. Floating washing tank(3-4 sets)

Flotation/sink tank separate the material according their density. PET sinks to the bottom and is discharged by a screw conveyor. Remains of caps and rings made of PE and labels of PP floats on the top and are moved by rotating shovels to side of washing tank. Small screw conveyor take them out. This machine removes 90% of paper and plastic labels.

5. Friction washing tank

The flakes are efficiently cleaned inside inclining drum with blades on rotor turn

- Q: Low pressure plastic raw materials in the process of blowing the two sides of the fold, how to deal with?

- The blowing ratio is one of the control points of blown film production and! Refers to the ratio between the bubble diameter and the diameter of not blowing blowing after.

- Q: What are the plastic bags made of?

- Barrels are usually produced in HDPE, and as for plastic bags, these materials can be made, including polypropylene. Relatively soft is made of high pressure material, relatively hard bag is made of low pressure material, hard and quite, is PP do. Linear low density polyethylene has a strong tear resistance and is generally improved by adding a certain percentage to high pressure polyethylene. The requirements are not too high to add some recycled materials and should be appropriate to reduce the cost of filling masterbatch.

- Q: Is the tableware made of PP raw material the best of those plastic tableware?

- Polypropylene (PP) is made from propylene. The transparency is also better than polyethylene. It is harder than polyethylene. Most of the boxes packed in the hotel are made of it. The plastic boxes can be heated in a microwave oven.

- Q: What is the specific material for plastic pallets?

- With excellent mechanical properties, its strength and elasticity are higher than HDPE, and it has good flexural fatigue resistance. It has good heat resistance and good chemical stability. Besides being concentrated by concentrated sulfuric acid and concentrated nitric acid, it is relatively stable to other chemical reagents. The high frequency insulation performance of polypropylene is excellent because of its almost no water absorption, so the insulation performance is not affected by temperature.

- Q: What can be added to the PP plastic material to prevent light transmission?

- Join the black color on the line! Plastic is black to prevent light from passing through

- Q: What type of raw material for plastic straw?

- The main component of plastics is resin. The term was first resin secrete by animal and plant lipid and its name, such as rosin, shellac, resin is not mixed with various additives and polymer compounds. Resin accounts for about 40% to 100% of the total weight of plastics.

- Q: Will plastic raw materials (such as PET, PP, etc.) be made of non-woven fabrics, will certainly contain BPA?

- BPA doesn't come out of thin air. PC uses BPA as raw material, so it comes with a little bit. Most plastics do not contain bpa. If you need to verify, you can test it and then ask the supplier to verify it. The electronic industry has done so, every level to find upstream suppliers signed a certificate of protection. We should ensure that mobile phone materials do not contain BPA, plasticizers and more than 150 substances.

- Q: Characteristics and uses of CA plastics

- Cellulose acetate (Cellulose Acetate, hereinafter referred to as CA, or cellulose acetate, cellulose acetate) was first prepared in 1865 and is the acetate of cellulose. CA used for photographic film base, is a component of some adhesive for synthetic fiber.

- Q: What are the raw materials needed for making plastic bags?

- In addition, the bag color and performance requirements are not high, you can choose recycled polyethylene. Plastic can be recycled, because of the repeated use of processing, non-toxic, tasteless new plastic become cloudy, less than the original hygiene and color requirements. But this plastic bag is made from recycled material, which is environmentally friendly, and the price is 10% to 50% lower than that of the new material bag

- Q: What are the properties of plastic material PS? What are the advantages and disadvantages?

- High temperature, high mold temperature and low injection pressure should be adopted to prolong the injection time. It is beneficial to reduce internal stress and prevent shrinkage and deformation

1. Manufacturer Overview

| Location | Suzhou, Jiangsu, China (Mainland) |

| Year Established | 2004 |

| Annual Output Value | US$50 Million - US$100 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia |

| Company Certifications | ISO 9001:2000; ce |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | |

Send your message to us

Waste Plastic PET Bottle Recycling Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 20 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords