Plastic Tubing

Plastic Tubing Related Searches

Primer For Galvanized Steel H S Code For Stainless Steel Wd 40 For Stainless Steel Spray Paint For Stainless Steel Drill Bits For Stainless Steel Sponge For Stainless Steel Caulking For Stainless Steel Steel Vessels For Kitchen Best Solar Inverter For Home Led Table Lamps For HomeHot Searches

Steel Mesh Panels For Sale Price For Stainless Steel Scrap Scrap Price For Stainless Steel Cheap High Tea Sets For Sale Stainless Steel Tanks For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Type Of Inverter For Solar Price Of Shipping Containers For Sale Stock Price For Aluminum Used Solar Inverter For Sale Portable Led Signs For Sale Stone Hot Water Bottles For Sale Large Led Screens For Sale Used Aluminum Scaffolding For Sale 1/4 Aluminum Plate For Sale Pvc Chairs For SalePlastic Tubing Supplier & Manufacturer from China

Okorder.com is a professional Plastic Tubing supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Plastic Tubing firm in China.Hot Products

FAQ

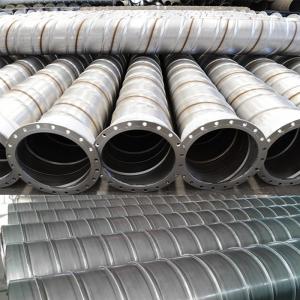

- Using pre-fabricated steel pipes in various applications has several advantages. Firstly, these pipes offer a high level of durability and strength due to the robustness and resistance of steel to external forces. This makes them ideal for withstanding high pressure or heavy loads, resulting in a longer lifespan compared to other materials and reducing the need for frequent replacements and maintenance. Secondly, pre-fabricated steel pipes provide excellent corrosion resistance by being coated with protective layers like galvanization or epoxy, preventing rusting and corrosion. This is especially important in industries or environments where the pipes may come into contact with moisture, chemicals, or other corrosive substances. By utilizing pre-fabricated steel pipes, the risk of leaks, deterioration, or failure due to corrosion is significantly reduced. Another advantage of these pipes is their versatility and ease of installation. They are manufactured to precise specifications before being delivered to the site, allowing for quick and efficient installation. Their modular nature enables easy assembly, disassembly, and reconfiguration, making them suitable for a wide range of applications. Additionally, pre-fabricated steel pipes can be seamlessly integrated with other building components, reducing installation time and costs. Furthermore, pre-fabricated steel pipes are more environmentally friendly compared to other materials. Steel is highly recyclable, and using pre-fabricated pipes reduces the consumption of natural resources and energy required for production. The long lifespan of steel pipes also reduces waste generation and the need for frequent replacements, contributing to sustainability efforts. Lastly, pre-fabricated steel pipes offer cost advantages. Although the initial cost may be higher than some other materials, their durability and low maintenance requirements result in long-term cost savings. The reduced need for repairs, replacements, and maintenance, along with the ease of installation, lead to lower overall project costs and reduced downtime. In summary, the advantages of pre-fabricated steel pipes include durability, corrosion resistance, versatility, ease of installation, environmental friendliness, and cost-effectiveness. These benefits make them the preferred choice for various industries and applications.

- Common methods for inspecting the integrity of steel pipes include visual inspection, ultrasonic testing, magnetic particle testing, radiographic testing, and pressure testing.

- What's the difference between a rectangular tube and a rectangular steel tube?

- The classification of rectangular tube: steel pipe seamless steel pipe and welded steel pipe (tube) hot-rolled seamless tube, seamless tube, seamless tube, welded tube extrusion. The welded square pipe is divided into two parts:(a) according to the process of arc welding - resistance welding tube, square tube (high frequency and low frequency), welding square tube, welding square tube furnace (b) according to the weld - welded square tube, spiral welded pipe.

- How long is the seamless tube?

- Welded pipe is generally 6912 meters fixed length, seamless pipe on the market in general non fixed foot, but usually more than 6 meters

- Steel pipes are insulated for thermal efficiency by adding a layer of insulation material around them. This insulation helps to reduce heat transfer through the pipes, preventing energy loss and maintaining the desired temperature.

- The quality and suitability of steel pipes are determined by grading them based on several factors. The grading system typically takes into account parameters such as the chemical composition, mechanical properties, manufacturing method, and testing standards. 1. When it comes to the chemical composition, steel pipes are graded according to the elements present in their composition. This includes the quantities of carbon, manganese, phosphorus, sulfur, and other alloying elements. The pipe's strength, corrosion resistance, and other properties are greatly influenced by its chemical composition. 2. The mechanical properties of steel pipes play a crucial role in determining their strength, flexibility, and resistance to pressure and temperature. These properties encompass tensile strength, yield strength, elongation, hardness, and impact toughness. Pipes with higher mechanical properties are generally given higher grades. 3. The manufacturing method used for steel pipes can vary, with options such as seamless, welded, or ERW (Electric Resistance Welding). The manufacturing method has an impact on the pipe's integrity, dimensional accuracy, and overall quality. For example, seamless pipes are considered to be of higher quality due to their uniformity and lack of weld seams. 4. Steel pipes are graded based on their adherence to specific testing standards. These standards ensure that the pipes meet the required quality criteria and are suitable for their intended applications. Common testing standards include ASTM (American Society for Testing and Materials), API (American Petroleum Institute), and EN (European Norms). Taking these factors into consideration, steel pipes are often assigned alphanumeric codes or specifications for grading. For instance, pipes used in the oil and gas industry may be graded as API 5L (American Petroleum Institute), while pipes used for structural purposes may be graded as ASTM A500 (American Society for Testing and Materials). In conclusion, the grading of steel pipes is determined by their chemical composition, mechanical properties, manufacturing method, and adherence to testing standards. These grades assist customers and manufacturers in selecting the appropriate pipes for specific applications, ensuring safety, durability, and efficiency across various industries.

- Steel pipes are commonly used in construction for various purposes such as structural supports, plumbing systems, and underground utility installations. They provide strength, durability, and flexibility, making them suitable for carrying fluids, gases, and structural loads. Steel pipes are often used in the construction of buildings, bridges, and infrastructure projects, ensuring reliable and long-lasting performance.

- Yes, steel pipes can be used for power plant construction. Steel pipes are commonly employed in power plants for various applications such as the transportation of fluids, steam, and gases, as well as for structural support. They offer high strength, durability, and resistance to extreme temperatures and pressures, making them suitable for the demanding conditions found in power plants.