Silane Cross-linkable Low Smoke Zero Halogen Flame Retardant Polyolefin Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Halogen Free flame retardant:

1. competitive price

2. 30 years of experience

3. stable quality

4. customized product

Halogen Free flame retardant:

1. Applications and cable specifications:

General type. Used as cross-likable low smoke halogen free insulation and jacket for electronic wires, cotton coverd wire for construction. Work temperature: -40 to 125 degree C .

2. Description:

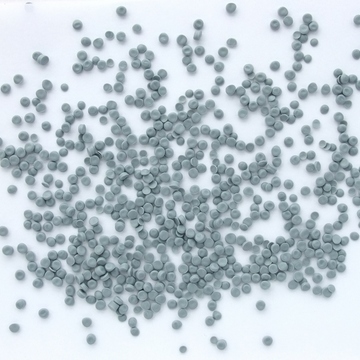

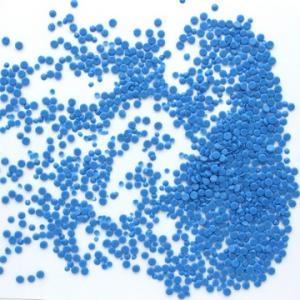

Silane crosslinkable low smoke halogen free POE compound, based on POE resin, is produced and pelletized by special technology, adding flame retardant, initiator, crosslinking agent and other special additives. This compound is composed of A materials and B materials, when it is used, please mix the A and B in the proportion of 97:3. This compound has advantage of excellent properties, processing easily, and excellent physical properties, meeting JB/T 10436-2004 standard.

3. Processing:

Equipment: it is recommended that this compound should be processed by professional screw for halogen free compound, with compression ratio of 1.2 to 1.5 (L:D should be 25 to 18). If you use PVC extruder, the speed should be lower and focus on cooling.

The following temperature(degree C) profile of extruder is recommended (temperature here is only for reference, and it will be different according to different extruder and temperature controlling equipment):

Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die |

Temperature | 110 | 140 | 160 | 160 | 165 | 170 |

Method of application:

(1) When you use this product, please mix A and B before put into the hopper. If you need color, the cable factory can use the polyvinylene masterbatch. The material should be used up after it opened in 8 hours and the rest can be resealed and usable within 24 hours.

(2) The extruder should be cleaned with PVC material after stopping, (It is preferable if you can take apart the screws to clean.)

(3) The silane crosslinkable LSZH compound should not be stayed in the extruder for a long time .If it stayed for long time, it will pre-crosslink after open the machine, which will make lumps in the surface of cable. It need to be discharged all the pre cross-linker, and then produce the cable properly.

(4) To ensure the safety and fully of the cross-linking, when immersed the compound into the hot water or steam, please calculate the cross-linking time based on the terms of more than 85℃, 8h/mm thickness cross-linking speed.

(5) At room temperature, the degree of crosslinking can also meet requirements after 7-10 days. The specific time can be different according to the temperature and humidity.

Note:

(1) Transportation: avoid direct sunlight and weathering and machine damage

(2) Convey: discharge softly, put off softly, avoid from the bursting by the stressed with the aluminum-plastic Bag.

(3) Storage: it can not be landing stack. It should be put on the pallet in the clean dry storage.

(4) Keep dry: When the material used, it must not be contained the outer water. Otherwise, it will seriously pre-crosslink.

(5) Quality guarantee period: 6 months after manufacturing.

4. Storage and transport:

Packaging:25kg/bag, Aluminum foil and PE film bag inside, and Kraft bag outside.

Storage and transport: Avoiding in direct sunlight and weathering. The storage should be clean, cool, dry, and ventilated.

5. Properties:

NO. | Item | Unit | GDW125A | GDW125C | GDW125H | |||

Standard | Typical | Standard | Typical | Standard | Typical | |||

1 | Density | g/cm3 | — | 1.44 | — | 1.38 | — | 1.43 |

2 | Tensile strength | MPa | ≥10 | 14.1 | ≥10 | 11.0 | ≥10 | 13.1 |

3 | Elongation at break | % | ≥150 | 240 | ≥150 | 230 | ≥150 | 230 |

4 | Hardness | Shore A | — | 97 | — | 91 | — | 97 |

5 | Thermal aging |

|

|

|

|

|

|

|

Condition: temperature | 158℃ |

|

|

|

|

|

| |

Time | 168h |

|

|

|

|

|

| |

TS retention | % | ≤±30 | -10 | ≤±30 | -12 | ≤±30 | -10 | |

EB retention | % | ≤±30 | -13 | ≤±30 | -10 | ≤±30 | -8 | |

6 | Thermal prolongation 200℃,0.2MPa,15min |

|

|

|

|

|

|

|

Elongation under load | % | ≤175 | 70 | ≤175 | 80 | ≤175 | 65 | |

Permanent deformation | % | ≤15 | 0 | ≤15 | 0 | ≤15 | 0 | |

7 | Volume Resistivity, at 20 degree C | Ω·m | ≥1.0×1012 | 2.3×1013 | ≥1.0×1012 | 2.0×1013 | ≥1.0×1012 | 2.1×1013 |

8 | Dielectric strength | MV/m | ≥20 | 28 | ≥20 | 28 | ≥20 | 29 |

9 | Resistance to thermal stress crack | h | ≥96 | pass | ≥96 | pass | ≥96 | pass |

10 | Resistance to environmental stress crack | h | ≥96 | pass | ≥96 | pass | ≥96 | pass |

11 | Oxygen Index |

| ≥30 | 36 | ≥30 | 30 | ≥30 | 36 |

12 | Smoke density flaming |

| ≤100 | 50 | ≤100 | 60 | ≤100 | 50 |

Non flaming |

| — | 130 | — | 150 | — | 120 | |

13 | Burst Size of HCL | mg/g | ≤5 | 0 | ≤5 | 0 | ≤5 | 0 |

14 | PH value |

| ≥4.3 | 6.7 | ≥4.3 | 6.5 | ≥4.3 | 6.3 |

15 | Conductivity | μS/mm | ≤10 | 0.8 | ≤10 | 0.6 | ≤10 | 0.9 |

16 | Toxicity Index |

| ≤3 | 1.2 | ≤5 | 1.3 | ≤5 | 1.3 |

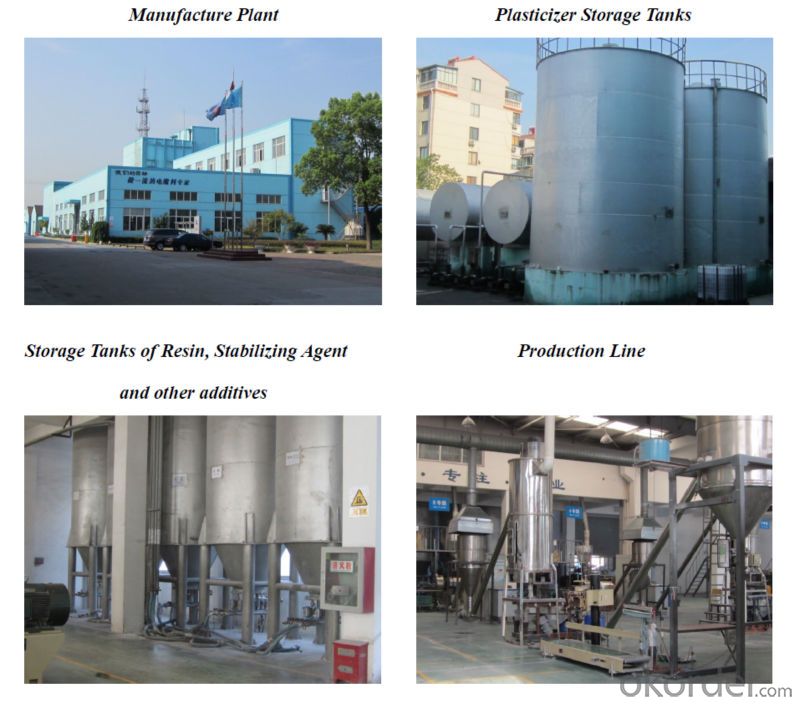

6. Company

- Q: Plastic pipe gas temperature 150 degrees, plastic pipe surface problems?

- Plastic pipe is usually plastic resin as raw material, adding stabilizers, lubricants, etc., to "plastic" method in the pipe mill by extrusion processing. Because of its light weight, corrosion resistance, beautiful appearance, no bad smell, easy processing, convenient construction and other characteristics, it has been more and more widely used in building engineering. Mainly used for building construction of the water supply system, piping, drainage, exhaust and sewage sanitary pipe, underground drainage pipe system, storm pipe and wire installation supporting the use of threading tubes, and so on.

- Q: Is the plastic with high melting index good?

- The melt index, the full melt flow index, or the melt flow index, is a numerical value that indicates the fluidity of the plastic material when it is processed.

- Q: How many types of plastics are there?

- PP: the name for polypropylene, five-star pin, handrails, floor mats and high strength is not necessary connections. Disadvantages: poor wear resistance and low surface hardness.

- Q: Plastic raw materials, why LDPE and LLDPE?

- LDPE is low density polyethylene, that is, high pressure material; LLDPE is linear material.

- Q: Commonly used plastic products, which are made of what raw materials, which can be recycled, I hope to get a professional answer in detail

- In daily life, we can directly contact or perceived plastic, is the most common plastics routine, mainly include five categories: PE (polyethylene), PP (polypropylene), ABS (acrylonitrile butadiene styrene plastic), PVC (polyvinyl chloride), PS (polystyrene), these five categories accounted for plastics the vast majority of plastic raw materials used, the basic can be classified as special plastic varieties, such as: PPS (PPS), PPO (polyphenylene ether), PA (polyamide), PC (polycarbonate), POM (POM), they are in daily life in the small amount of the product, mainly used in industry and engineering the national defense science and technology and other high-end fields, such as automotive, aerospace, construction, communications and other fields.

- Q: How is plastic material made out?

- At present, resins are polymers that have not yet been blended with additives. Resin accounts for about 40% to 100% of the total weight of plastics. The basic properties of plastics depend mainly on the nature of the resin, but additives also play an important role.

- Q: Is the tableware made of PP raw material the best of those plastic tableware?

- 1 polyethylene terephthalate (PET) is made up of ethylene. Used as mineral water bottles, cola beverage bottles, fruit juice bottles, etc.. Because it can only heat 120 degrees, so only suitable for cold and warm drink, if installed high temperature liquid or heating deformation.2. High density polyethylene (HDPE), suitable for food and medicine bottles, cleaning supplies and bath products, shopping bags, garbage cans.3. Polyvinyl chloride (PVC) is polymerized from vinyl chloride. High temperature and contact with grease, PVC easily release phthalate two formic acid and incompletely polymerized toxic vinyl chloride monomer. PVC film made of PVC, transparent, difficult to break, strong adhesion, low prices, we see in the supermarket, supermarkets on the box firmly glued to the film is it. According to its characteristics, it is only suitable for vegetables and fruits refrigerated preservation, it is not appropriate to put meat, cakes and other foods containing more fat, it should not be used as microwave heating

- Q: What are the raw materials for environmental friendly portable plastic bags?

- Now, environmental protection is only relative, that is, in PP or PE added starch, discarded starch degradation, but PP and PE still, but not as before, all plastic are not degraded only. Fully biodegradable environmentally friendly plastics have not been produced on a large scale, such as carbon dioxide or polylactic acid.

- Q: What is the raw material for producing corn starch plastic film?

- According to the current technical level, the production of 1 tons of starch requires 1.5 tons of corn, power consumption of 200KWh, coal consumption of 0.3 tons. If the 1 tons of starch into biomass plastics, can be processed into 1.01.2 tons of products, instead of common plastics, saving petrochemical resources, the country. Because there is no effective stimulating mechanism in the downstream market, the application of corn starch is still limited to the research area of modified starch. The industrialization of biomass plastics with corn starch as the main raw material will effectively stimulate the cultivation of corn and the production of cornstarch. Biomass plastics are gradually evolved from the further research and development of biodegradable plastics. It is gradually recognized that only by fully utilizing the natural and recyclable plant resources to develop and develop biomass plastics is a reliable way to achieve sustainable economic development. In the past 30 years, and in half a century, all countries in the world pay attention to and invest a lot of manpower and material resources of biomass plastics, mainly starch and biodegradable plastics mixing, carbon dioxide copolymer, biosynthesis of biodegradable plastics, and then generate a biosynthetic precursor chemical polymerization of biodegradable plastics in 4 categories. The latter three prices are higher, but the cost is higher, mainly used in medical materials, biomedical engineering and tissue engineering and other high-value products.

- Q: What are the plastic raw materials for this purpose?

- Plastic classification, composition and characteristics, plastic is a widely used synthetic polymer materials, in our daily life, plastic products abound.

Send your message to us

Silane Cross-linkable Low Smoke Zero Halogen Flame Retardant Polyolefin Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches