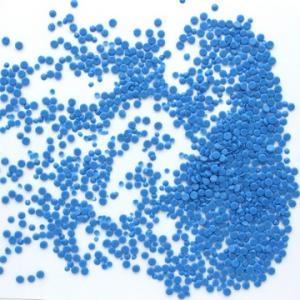

Silane Cross-linkable Low Smoke Zero Halogen Flame Retardant EPDM Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

epdm rubber cable:

1, 30-year professional manufacturer

2, low-smoke, halogen-free, flame retardant

3, UL and CM grade

epdm rubber cable:

1. Type and application

Type | Product | Application and Cable Specification |

GDWE1125 | 125 degree C Silane Cross-linkable Low Smoke Halogen Free Flame Retardant EPDM Compound | Used as insulation for low voltage cables, flexible cables, and rubber insulation and jacket for 105 degree C and 125 degree C cross-linkable low smoke halogen free cables Work temperature: -40 to 125 degree C |

GYJE-20 | Silane Cross-linkable EPDM Insulating Compound | Used as rubber insulation for 15 to 20 KV cables and flexible cables, and rubber insulation and jacket for 70 degree C to 125 degree C cables Work temperature: -40 to 125 degree C |

GYJE-10 | Silane Cross-linkable EPDM Insulating Compound | Used as rubber insulation for less than 10 KV cables and flexible cables, and rubber insulation and jacket for 70 degree C to 125 degree C cables Work temperature: -40 to 125 degree C |

2. Description

Silane cross-linkable EPDM rubber compound, based on EPDM and other copolymer, is produced and pelletized by special technology, adding some flame retardant, initiating agent, cross-linking agent, and some other suitable additives. This compound contains two parts A and B, which should be mixed according to suitable proportion when used. This compound has well performance of processing easily, physical properties, and cost advantage with low density.

3. Processing

The following temperature(℃) profile of extruder is recommended:

Type | Proportion of A and B | Processing Equipment | Compression ratio | L/D | Processing temp. | Cross-linkable conditions | |||||

Z 1 | Z2 | Z3 | Z4 | Head | Die | ||||||

GDWE1125 | 90:10 | It is better to use professional extruder for halogen free compound. If you use PVC extruder, the speed should be lower, reinforce cooling | 1.2~1.5:1 | 25:1~ 18:1 | 100 | 140 | 160 | 160 | 165 | 170 | Hot water or steam, based on the terms of more than 85℃, 4h/mm thickness cross-linking speed |

GYJE-20 GYJE-10 | 97:3 | Conventional PVC extruder | 2.5:1~3.5:1 | 25:1 | 110~170℃ | 180-190℃ | |||||

method of application:

1. When you use this product, please mix A and B before put into the hopper. If you need color, the cable factory can use the polyvinylene masterbatch. The material should be used up in 8 hours after being opened and the rest can be resealed and usable within 24 hours.

2. The extruder should be cleaned after stopping with PVC material, (It is preferable if you can take apart the screws to clean.)

3. The silane cross-linkable LSZH compound should not be stayed in the extruder for a long time .If it stayed for long time, it will pre-crosslink after open the machine, which will make lumps in the surface of cable. It need to be discharged all the pre cross-linker, and then produce the cable properly.

4. To ensure the safety and fully of the cross-linking, when immersed the compound into the hot water or steam, please calculate the cross-linking time based on the terms of more than 85℃, 8h/mm thickness cross-linking speed.

5. At room temperature, the degree of cross-linking can also meet requirements after 4-10 days. The specific time can be different according to the temperature and humidity.

Note:

1. Transportation: avoid direct sunlight and weathering and machine damage

2. Convey: discharge softly, put off softly, avoid from the bursting by the stressed with the aluminum-plastic Bag.

3. Storage: it can not be landing stack. It should be put on the pallet in the clean dry storage.

4. Keep dry: When the material used, it must not be contained the outer water. Otherwise, it will seriously pre-crosslink.

5. Quality guarantee period: 6 months after manufacturing.

4. Storage and transport

Packaging:Vacuum Aluminum foil and PE membrane inside bag, and kraft outside bag.

Storage and transport: Avoiding in direct sunlight and weathering. The storage place should be clean, cool, dry, and ventilated.

5. Properties

Note: The below data is got after the compound boiled in 80 degree C water 4 hours. Natural crosslink can also be finished at proper temperature and in proper time.

NO. | Item | Units | GDWE1125 | GYJE-20 | GYJE-10 | |||

Standard Vaule | Typical Value | Standard Vaule | Typical Value | Standard Vaule | Typical Value | |||

1 | Density | g/cm3 | — | 1.35 |

| 0.9 |

| 0.88 |

2 | Tensile Strength | MPa | ≥10 | 12.0 | ≥16 | 23.0 | ≥16 | 21.0 |

3 | Elongation at break | % | ≥150 | 250 | ≥300 | 530 | ≥300 | 540 |

4 | Hardness | Shore A | — | 90 |

| 90 |

| 70 |

5 | Thermal aging |

|

|

|

|

|

|

|

Conditions: temperature | 158℃ |

|

|

|

|

|

| |

time | 168h |

|

|

|

|

|

| |

TS retention | % | ≤±30 | -11 | ≤±30 | -6 | ≤±30 | -8 | |

EB retention | % | ≤±30 | -10 | ≤±30 | -8 | ≤±30 | -7 | |

6 | Thermal prolongation |

|

|

|

|

|

|

|

200℃,0.2MPa,15min |

|

|

|

|

|

|

| |

Elongation under load | % | ≤175 | 80 | ≤175 | 70 | ≤175 | 70 | |

Permanent deformation | % | ≤15 | 0 | ≤15 | 0 | ≤15 | 0 | |

7 | Volume Resistivity | Ω·m | ≥1.0×1012 | 2.3×1013 | ≥1.0×1013 | 1.0×1014 | ≥1.0×1013 | 1.0×1014 |

8 | Dielectric Strength | MV/m | ≥20 | 28 | ≥25 | 35 | ≥25 | 32 |

9 | Resistance to thermal stress crack | h | ≥96 | pass |

|

|

|

|

10 | Resistance to environment stress crack | h | ≥96 | pass |

|

|

|

|

11 | Oxygen Index |

| ≥30 | 30 |

|

|

|

|

12 | Smoke density Flaming |

| ≤100 | 60 |

|

|

|

|

Non flaming |

| — | 180 |

|

|

|

| |

13 | Burst size of HCL | mg/g | ≤5 | 0 |

|

|

|

|

14 | PH Value |

| ≥4.3 | 5.6 |

|

|

|

|

15 | Conductivity | μS/mm | ≤10 | 0.6 |

|

|

|

|

16 | Toxicity Index |

| ≤5 | 1 |

|

|

|

|

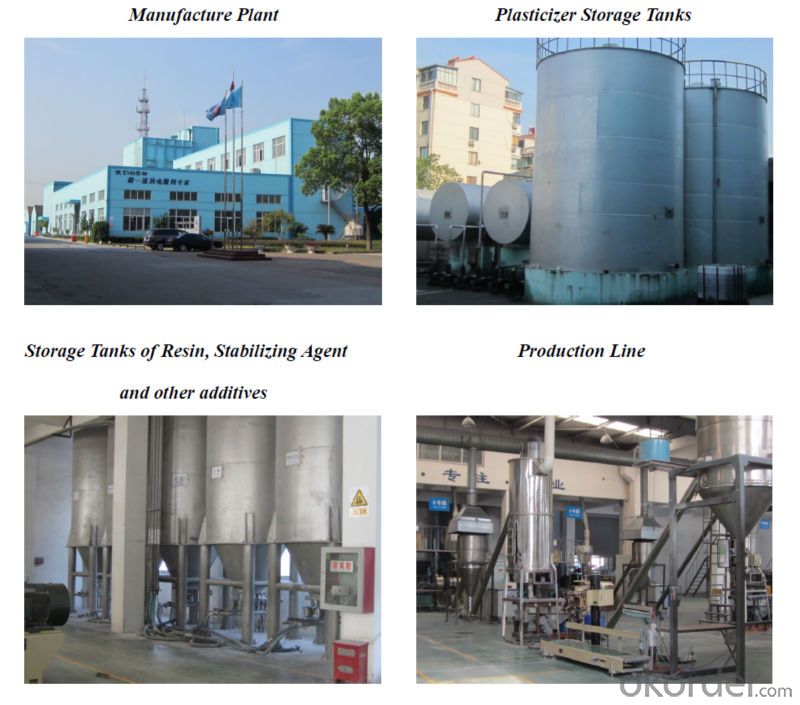

6, Company Pictures of epdm rubber cable

- Q:What is the concept of plastic raw materials for turnover containers?

- Plastic turnover box, other features: 1) plastic turnover box outer dimension refers to the maximum size of the logistics box cover. 2) the plastic turnover box has no standard inner concave, and the case size is 18mm. 3) the carrying capacity of a plastic turnover box means that the load is uniformly placed within the range of the environmental temperature. 4) the effective working temperature of the plastic turnover box is -25 DEG C - 40 DEG C. 5) plastic turnover boxes can be stacked for storage, saving space.

- Q:Plastic pipe gas temperature 150 degrees, plastic pipe surface problems?

- Plastic pipe is usually plastic resin as raw material, adding stabilizers, lubricants, etc., to "plastic" method in the pipe mill by extrusion processing. Because of its light weight, corrosion resistance, beautiful appearance, no bad smell, easy processing, convenient construction and other characteristics, it has been more and more widely used in building engineering. Mainly used for building construction of the water supply system, piping, drainage, exhaust and sewage sanitary pipe, underground drainage pipe system, storm pipe and wire installation supporting the use of threading tubes, and so on.

- Q:Will plastic raw materials (such as PET, PP, etc.) be made of non-woven fabrics, will certainly contain BPA?

- BPA doesn't come out of thin air. PC uses BPA as raw material, so it comes with a little bit. Most plastics do not contain bpa. If you need to verify, you can test it and then ask the supplier to verify it. The electronic industry has done so, every level to find upstream suppliers signed a certificate of protection. We should ensure that mobile phone materials do not contain BPA, plasticizers and more than 150 substances.

- Q:How is plastic material made out?

- The main components of plastic resin (in the early stage of coal tar products and calcium carbide carbide, it is used for oil and natural gas products, such as ethylene, propylene, benzene, formaldehyde and urea).

- Q:What are the main biodegradable plastic bags made of?

- At present, developed a new biodegradable plastic, its composition is polyvinyl alcohol starch plus photosensitizer synthesis, polyvinyl alcohol was easy to degrade than polyethylene, adding photosensitizer can absorb sunlight to accelerate the degradation by plastic, starch can promote the degradation of plastic in soil speed. As a result, this new biodegradable plastic is easier to degrade than the former, and it decomposes into a substance of simple molecular structure, such as carbon and water, which is more environmentally friendly.

- Q:What are the materials for making plastic buckets? How many are there?

- Domestic plastic bucket source material basically two kinds: blow molding with PE injection: PP

- Q:Can PE material be used as food grade plastic?

- Plastic film PE the main consumption areas, because of its more and more used in consumption and transportation, the development of the relationship between demand and the overall economic situation is bigger, basically maintain a slightly higher than the national GDP growth, the growth momentum of stable existence of rigid demand. From the flexible packaging film production statistics, since 2006, the average increase rate of 13%, but also confirms the steady growth of plastic film. Another important consumption area of polyethylene is plastic pipe, and its output increases with the pace of urbanization in China, and the increase of municipal pipeline construction projects is increasing. In the next few years, the municipal water supply and drainage, gas pipelines, and urban underground power, communication, sheathing and pipelines will continue to be the focus of development in recent years.

- Q:Is plastic bucket and plastic bottle the same raw material?

- When the number of the triangle in the bottom of the plastic bucket is 2, the main component of this kind of plastic barrel is high-density polyethylene, or HDPE. This kind of plastic barrel has a higher melting point than PET plastic barrel, but the heat resistance can not reach 100 centigrade. HDPE itself is non-toxic. But this kind of plastic barrels in the production process used in some processed or modified additives, such as fillers, stable additives or pigments, these materials contain harmful substances, so this kind of plastic barrels after use not when the containers or other articles.

- Q:What is the difference between PP raw material and modified PP?

- Sort:(1) according to the characteristics of resin when heating and cooling, classification: 1. Thermosetting plastics, two, thermoplastics(2) according to the use of plastics classification: general plastic, engineering plastics, special plastic raw materialsModified PPThe concept of modified plastic PP, refers to the base of the general plastics and engineering plastics, after filling, blending and enhancement processing method of modification, improve the performance of flame retardant plastic products, strength, impact resistance, toughness.Classification: PP modified plastic products are mainly a variety of flame retardant resins, toughening resin, plastic alloy, functional masterbatch etc..

- Q:What is the ash content of PP plastic raw materials?

- PP if a few raw materials mixed with ash, and the color of raw material and color, it is PP powder, the water can not be dissolved. Try, if it is more, and the color is white, it is talcum powder or toner, water or dissolved or muddy water

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Silane Cross-linkable Low Smoke Zero Halogen Flame Retardant EPDM Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products