Plastic Coated Composite Steel Water Supply Tubes

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

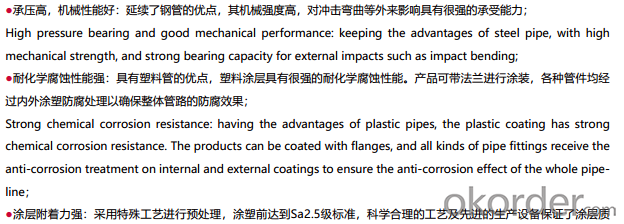

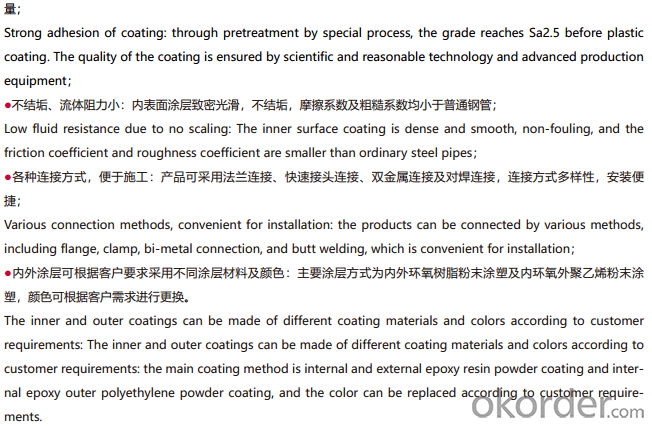

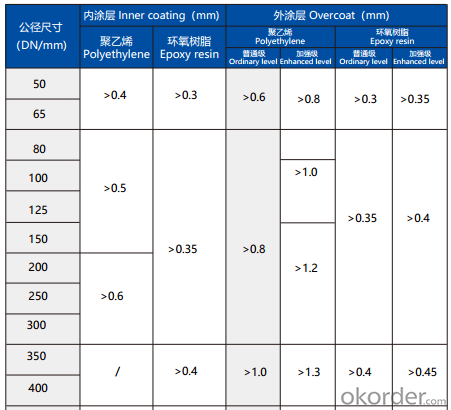

Coated Composite Steel Pipe for Water Supply System

DN50MM-DN1600MM

We own three industry bases for manufacturing pipes, fittings and new materials, including the biggest production line of steel wire reinforced PE composite pipe in the world, and top advanced PE pipe production line.

We get long term cooperation with leading material suppliers in the world and professionally provide the pipeline system solutions of matched products and technical cases by the whole industry chain from materials R&D to pipeline engineering installation.

- Q: How do you transport plastic tubes?

- Plastic tubes can be transported by packaging them securely in boxes or crates to prevent damage. They can also be transported in bulk using pallets and stretch wrap for stability. It is important to handle them with care to avoid any deformation or breakage during transportation.

- Q: What are the different diameter ranges available for plastic tubes?

- The diameter ranges available for plastic tubes vary depending on the specific application and manufacturer. However, commonly available diameter ranges for plastic tubes can range from as small as a few millimeters to several inches in diameter.

- Q: Are plastic tubes suitable for DIY projects?

- Yes, plastic tubes are suitable for DIY projects. They are versatile, lightweight, and easy to work with. Whether it's for plumbing, crafting, or organizing, plastic tubes can be easily cut, shaped, and connected to fit various project needs.

- Q: Can plastic tubes be used for electrical wiring protection?

- Yes, plastic tubes can be used for electrical wiring protection. Plastic tubes, such as PVC or polyethylene conduits, are commonly used to encase electrical wires and provide insulation and protection from moisture, dust, and physical damage. They are a cost-effective and versatile option for protecting electrical wiring in various applications.

- Q: How do plastic tubes compare to nylon tubes in terms of strength?

- Plastic tubes and nylon tubes have different properties, but in terms of strength, nylon tubes are generally considered to be stronger than plastic tubes. Nylon has a higher tensile strength and is more resistant to impact, making it suitable for applications that require durability and toughness.

- Q: im just wondering

- I believe the best way to protect your ear from getting water in it is to purchase moldable wax like ear plugs. It's cleaner and safer than cotton mixed with vaseline which may clog the tube and attract dirt in the ear canal. They are fine for swimming and showering.

- Q: i went to a house party and they were passing them around, i remember they were in a plastic tube and the were brightly colored, im throwing a party and we're gonna have grow in the dark things and alot of color and those would fit in good with my theme

- You mean glow sticks? Dollar store.

- Q: Are plastic tubes suitable for automotive applications?

- Yes, plastic tubes are suitable for automotive applications. They are lightweight, durable, and resistant to corrosion, making them ideal for various automotive systems such as fuel lines, coolant hoses, and air intake systems. Additionally, plastic tubes can be easily molded into different shapes and sizes, allowing for customization and efficient installation in vehicles.

- Q: My bff is challenging me to escape from a plastic tube approx. 4 ft. in diameter. I cannot carry any sharp items or tools that might be used to cut the plastic. If i get out in less than 2 hrs. then she will give me $400 in cash. I really need the money for my two kids. HELP!

- Use a blow torch. It's not sharp and it doesn't cut the plastic, it melts it so it's not against the rules.

- Q: in my home's a#92;c internal unit there is a rotating plastic tube where the cool air is blowing from. what is the name of this spare part? thanks.

- do you mean the fan ? also called a squirrel cage .

Send your message to us

Plastic Coated Composite Steel Water Supply Tubes

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords