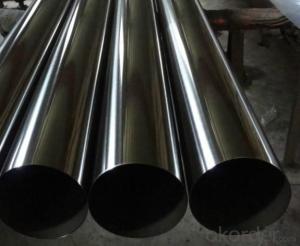

Stainless Steel Pipes

Stainless Steel Pipes Related Searches

Stainless Steel Piping Stainless Steel Tubes Pipe Stainless Stainless Steel Wires Stainless Steel Threaded Pipe Stainless Steel Pipe Screens Stainless Steel Screen Pipe Stainless Steel Chimney Pipe Stainless Steel Tape Stainless Steel Flue Pipe Stainless Steel Pipe Clamps Stainless Steel Pipe Fitting Stainless Steel Smoker Pipe Stainless Steel Pipe Suppliers 2 Stainless Steel Pipe 4 Stainless Steel Pipe Stainless Steel Strips 3 Stainless Steel Pipe Stainless Steel Flex Pipe 1 Stainless Steel Pipe Stainless Steel Pipe Sizes Stainless Steel Tap Stainless Steel Tubeing Chimney Pipe Stainless Steel Stainless Steel Plates Stainless Steel Tiles Stainless Steel Straps 6 Stainless Steel Pipe Stainless Steel Tubs Stainless Steel DoorsStainless Steel Pipes Supplier & Manufacturer from China

Stainless Steel Pipes are a type of pipe made from stainless steel, known for their excellent corrosion resistance and durability. These pipes are widely recognized for their ability to withstand harsh environments and maintain their structural integrity over time. They are commonly used in various industries, including construction, oil and gas, food processing, and pharmaceuticals, where their resistance to corrosion and ability to maintain cleanliness are essential. Stainless Steel Pipes are also preferred for their ease of installation and low maintenance requirements, making them a popular choice for many applications.In terms of usage scenarios, Stainless Steel Pipes are employed in a multitude of applications due to their versatility and strength. They are used in the transportation of fluids, such as water, chemicals, and gases, as well as in structural applications where their resistance to corrosion and high-temperature performance are critical. These pipes are also favored for their aesthetic appeal, making them suitable for architectural and decorative purposes. Their ability to maintain a hygienic surface makes them ideal for use in food and beverage processing facilities, where contamination must be minimized.

Okorder.com is a leading wholesale supplier of Stainless Steel Pipes, boasting a vast inventory that caters to the diverse needs of various industries. As a reputable supplier, Okorder.com ensures that the pipes they offer meet the highest quality standards, adhering to international specifications and certifications. Their extensive range of Stainless Steel Pipes includes different grades, sizes, and finishes, allowing customers to select the most suitable product for their specific requirements. With a commitment to customer satisfaction and a focus on providing competitive pricing, Okorder.com has established itself as a trusted source for Stainless Steel Pipes in the global market.

Hot Products