Round Stainless Steel Tube

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25-35 kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | JIS,AISI,ASTM,GB,DIN,CE | Place of Origin: | Guangdong China (Mainland) | Brand Name: | QX |

| Model Number: | 201/202/304/316/316L/430 | Type: | Welded | Steel Grade: | 300 Series |

| Application: | Decoration,construction, upholstery | Certification: | ISO | Welding Line Type: | ERW |

| Thickness: | 0.3mm to 3.0mm | Outer Diameter: | 9.53mm to 159mm | Polish: | Satin,Bright or Mirror |

| Grade: | 201,202,301,304,316,316l,430 ect. | Length: | In gernal 5.8m/6m or as customer request | Process method: | Hot rolled |

| Test: | Squash test, water pressure test,extended test,crystal rot test etc. | Production Standard: | ASTM A554 | Materials: | SUS 304, 201, 316, 316L,430 ect |

| OD tolerance: | + / - 0.15mm | Thickness tolerance: | +/- 10% | Length tolerance: | +/- 10mm |

Packaging & Delivery

| Packaging Detail: | Every tube is sleeved in plastic bag individually, and then several tubes are packed by weaving bag, which is seaworthy. Or 50kg/bundle, 500kg/bundle.We can pack as clients' requirement. |

| Delivery Detail: | 25 - 35 days for a full container. |

Specifications

Stainless Steel Pipe:

1.201,202,301,304,316L,430,etc

2.OD:6mm-159mm

3.Thickness:0.25mm-3.5mm

4.Finish:Mirror,Satin,Hairline

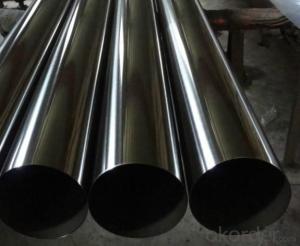

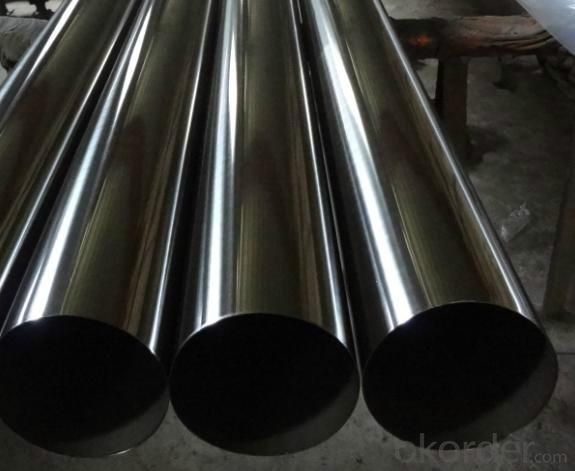

Stainless Steel Tube Image

FAQ of Stainless Steel Pipe

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

Any question, pls feel free to contact us !

- Q: What are the common protective coatings used on the inner surface of steel pipes?

- The common protective coatings used on the inner surface of steel pipes include epoxy, polyurethane, and cement mortar coatings. These coatings provide corrosion resistance, prevent the formation of scales, and improve the durability and lifespan of the pipes.

- Q: Can steel pipes be used in extreme weather conditions?

- Yes, steel pipes can be used in extreme weather conditions. Steel is known for its high strength and durability, making it suitable for a wide range of applications including construction, infrastructure, and transportation. Steel pipes are commonly used to transport fluids and gases in various industries, and they are designed to withstand harsh environmental conditions, including extreme temperatures, high pressures, and corrosive environments. In extreme weather conditions such as extreme heat, cold, or heavy rain, steel pipes can maintain their structural integrity and functionality. Additionally, steel pipes can be coated or insulated to provide additional protection against corrosion and to maintain desired temperatures. Overall, steel pipes are a reliable choice for use in extreme weather conditions due to their strength, durability, and resistance to various environmental factors.

- Q: How are steel pipes tested for leakage?

- Steel pipes are tested for leakage through various methods, including hydrostatic testing and ultrasonic testing. In hydrostatic testing, the pipes are filled with water under high pressure to check for any leaks or weaknesses in the welds or seams. Ultrasonic testing involves using high-frequency sound waves to detect any defects or cracks in the pipes. Both methods are effective in ensuring the integrity and leak-free performance of steel pipes.

- Q: How are steel pipes sized and classified?

- Steel pipes are sized and classified based on their outer diameter, wall thickness, and length. The sizing is done using standard measurements such as nominal pipe size (NPS) or nominal diameter (DN). Classification is determined by factors such as the pipe's pressure rating, material composition, and intended use. This helps ensure compatibility and proper installation in various applications such as plumbing, construction, and industrial processes.

- Q: How do you calculate the stress in a steel pipe?

- To calculate the stress in a steel pipe, you need to consider the material properties of the steel and the external forces acting on the pipe. The stress in a pipe is typically calculated using the formula: Stress = Force / Area First, you need to determine the force acting on the pipe. This could be due to external loads such as pressure, weight, or mechanical forces. You can calculate the force by multiplying the pressure or weight by the surface area on which it acts. For example, if the pipe is subjected to an internal pressure, you can calculate the force using the formula: Force = Pressure x Area Next, you need to determine the cross-sectional area of the pipe. The cross-sectional area of a circular pipe can be calculated using the formula: Area = π x (Diameter / 2)^2 Once you have determined the force and the area, you can calculate the stress by dividing the force by the area. This will give you the stress value in units such as pounds per square inch (psi) or newtons per square meter (Pa). It is important to note that the stress calculation assumes that the pipe is in a state of equilibrium and that the material properties of the steel are known. The material properties, such as yield strength and ultimate tensile strength, are used to ensure that the stress calculated does not exceed the maximum capacity of the steel.

- Q: What is the difference between Schedule 40 and Schedule 80 steel pipes?

- The main difference between Schedule 40 and Schedule 80 steel pipes lies in their wall thickness. Schedule 40 pipes have a thinner wall, making them suitable for low-pressure applications, while Schedule 80 pipes have a thicker wall, enabling them to withstand higher pressure.

- Q: What are the different types of steel pipe supports for high-temperature applications?

- Some different types of steel pipe supports for high-temperature applications include hangers, clamps, brackets, and anchors. These supports are designed to withstand the elevated temperatures and provide stability and proper alignment to the piping system.

- Q: What are the different types of joints used in steel pipes?

- The different types of joints used in steel pipes include butt weld, socket weld, threaded, and flanged joints.

- Q: What are the common maintenance practices for steel pipes?

- The common maintenance practices for steel pipes include regular inspections for signs of corrosion or damage, cleaning and removing any debris or obstructions, applying protective coatings to prevent rust and corrosion, and conducting periodic leak tests to ensure the integrity of the pipes. Additionally, proper handling and storage procedures should be followed to prevent any physical damage or contamination.

- Q: Steel pipe is particularly long, how to clean the inner wall of the pipe so that it can be thoroughly cleaned

- If the pipe is relatively long, you have water, you can buy ultrasonic vibration plate into the water for ultrasonic cleaning, if not too long with an ultrasonic vibration rod, inserted into the pipe cleaning, and then rinse with water by ultrasonic stripping of dirt, give you recommend a factory in Jining Hengda

Send your message to us

Round Stainless Steel Tube

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25-35 kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords