Oil Casing and Casing Pipe API-5CT,J/K55, N80, L80/P110

- Loading Port:

- Baoshan Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50MT m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Best quality of Oil Casing and Casing Pipe API-5CT,J/K55, N80, L80/P110 with good price .

Seamless steel tubes can be used for a wide range transferring of oil, gas, and mine liquid, construction projects, chemical industry, power plant, Offshore platform etc.And the tubes are suitable cold bending and for galvanizing at customers request.

Specification of Oil Casing and Casing Pipe API-5CT,J/K55, N80, L80/P110,

Standard: APL SPEC 5CT

Length

|

|

(Range 1) |

(Pange 2) |

(Pange 3) |

|

Tubing |

6.10-7.32m |

8.53-9.75m |

11.58-12.80m |

|

Casing |

4.88-7.62m |

7.62-10.36m |

10.36-14.63m |

|

Pup Joint |

0.5m-6.0m(2FEET-20FEET) | ||

Chemical Composition (%)

|

Grade |

Chemical Composition% | ||||||||||||

|

C |

Mn |

Mo |

Cr |

Nl |

Cu |

P |

S |

Si | |||||

|

min |

max |

min |

max |

min |

max |

min |

max |

max |

max |

max |

max |

Max | |

|

J55 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.030 |

0.030 |

- |

|

K55 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.030 |

0.030 |

- |

|

N80-1 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.030 |

0.030 |

- |

|

N80Q |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.030 |

0.030 |

- |

|

M65 |

- |

0.43 |

- |

1.90 |

- |

- |

- |

- |

0.25 |

0.35 |

0.030 |

0.030 |

0.45 |

|

L80-1 |

- |

0.35 |

- |

1.00 |

0.25 |

0.75 |

- |

1.2 |

0.99 |

- |

0.020 |

0.010 |

- |

|

C90-1 |

- |

0.50 |

- |

1.90 |

- |

NL |

- |

NL |

0.99 |

- |

0.030 |

0.010 |

- |

|

C90-2 |

- |

0.45 |

- |

1.90 |

- |

- |

- |

- |

- |

- |

0.030 |

0.030 |

0.45 |

|

C95 |

- |

0.35 |

- |

1.20 |

0.25 |

0.85 |

0.40 |

1.50 |

0.99 |

- |

0.020 |

0.010 |

- |

|

T95-1 |

- |

0.50 |

- |

1.90 |

- |

- |

- |

- |

0.99 |

- |

0.030 |

0.010 |

- |

|

T95-2 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.030 |

0.45 |

|

P110 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.030 |

0.45 |

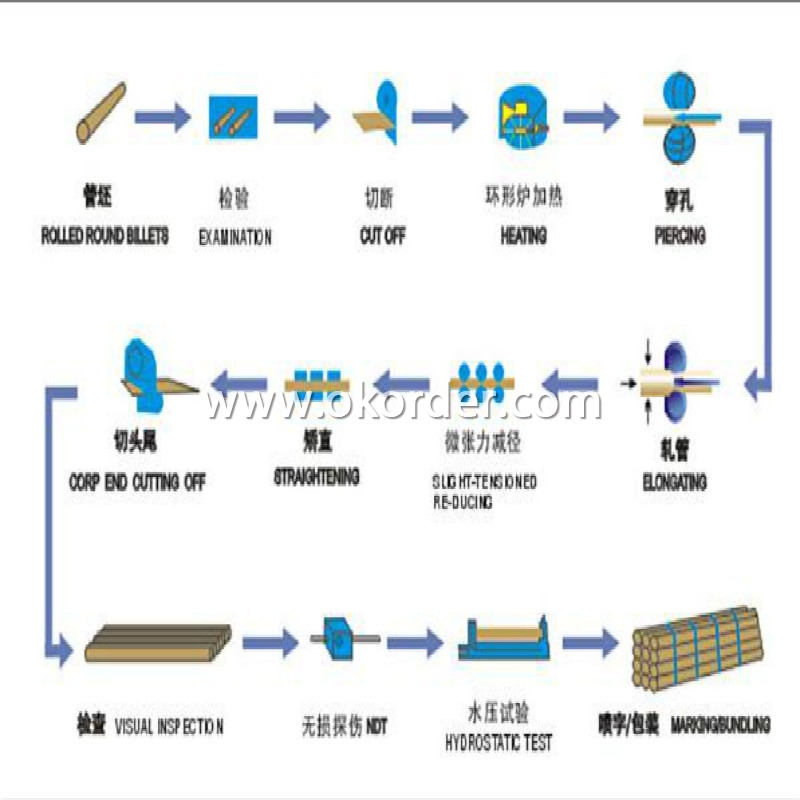

Picturers of Oil Casing and Casing Pipe API-5CT,J/K55, N80, L80/P110

Advanced production line.

Stock at warehouse.

Production process.

Our products are exported to South and East Asia, Middle East, Europe and American, and enjoyed a good reputation ,we are a well-known manufacturer of seamless steel tubes in China. Steel tubes suitable for seamless and threading are manufactured according to standard ASME B36 10, ASTM A106/A53, API 5L/5CT, DIN.

Welcome to visit us for more information and order Oil Casing and Casing Pipe API-5CT,J/K55, N80, L80/P110.

- Q: How are steel pipes used in desalination plants?

- Steel pipes are used in desalination plants to transport and distribute the seawater and treated water throughout the facility. They are durable and resistant to corrosion, ensuring the efficient and reliable movement of water in the desalination process.

- Q: Are steel pipes suitable for underground mining operations?

- Yes, steel pipes are suitable for underground mining operations. Steel pipes are known for their durability, strength, and resistance to corrosion, making them ideal for use in harsh underground mining environments. They can withstand high pressure and are capable of transporting various substances, such as water, air, or mining materials, with reliability and efficiency. Additionally, steel pipes can be customized to meet specific mining requirements, ensuring their suitability for underground operations.

- Q: How do you calculate the pipe deflection for steel pipes?

- To calculate the pipe deflection for steel pipes, you need to consider factors such as the length, diameter, material properties, applied load, and support conditions. The most common method is using structural analysis software or referring to relevant engineering codes and standards, which provide formulas and calculation procedures specific to steel pipes. These calculations determine the deflection at various points along the pipe, considering its stiffness and the applied loads.

- Q: What is the difference between steel pipe and tubing?

- The main difference between steel pipe and tubing lies in their shape and size. Steel pipe is typically cylindrical in shape and has a larger diameter compared to tubing, which is generally produced in a variety of shapes, including round, square, and rectangular, with smaller diameters. Additionally, steel pipe is commonly used for transporting fluids and gases, while tubing is often utilized for structural applications or as components in mechanical systems.

- Q: What are the different manufacturing standards for steel pipes?

- There are several manufacturing standards for steel pipes that are widely recognized and implemented in the industry. These standards ensure that the steel pipes are produced to meet specific requirements and quality standards. Some of the most common manufacturing standards for steel pipes include: 1. American Society for Testing and Materials (ASTM): ASTM standards are widely used in the United States and cover a wide range of steel pipe specifications. These standards include specifications for seamless and welded steel pipes, as well as various grades and dimensions. 2. International Organization for Standardization (ISO): ISO standards are globally recognized and provide guidelines for the production of steel pipes. ISO standards cover areas such as dimensions, materials, testing, and quality control. 3. European Norm (EN): EN standards are applicable in Europe and provide specifications for various types of steel pipes. These standards cover aspects such as dimensions, materials, manufacturing processes, and testing. 4. Japanese Industrial Standards (JIS): JIS standards are widely used in Japan and have gained international recognition. These standards cover dimensions, materials, and testing methods for steel pipes. 5. British Standards (BS): BS standards are commonly used in the United Kingdom and cover a range of steel pipe specifications. These standards include requirements for dimensions, materials, and testing procedures. 6. American Petroleum Institute (API): API standards are specifically developed for the oil and gas industry and cover various aspects of steel pipe manufacturing. These standards include specifications for seamless and welded pipes used in oil and gas exploration, production, and transportation. It is important for manufacturers, buyers, and users of steel pipes to be aware of these standards to ensure the quality, compatibility, and reliability of the pipes. Compliance with these standards helps to ensure that the steel pipes meet the necessary requirements and are suitable for their intended applications.

- Q: How to make the steel pipe spray paint is not easy to fall off?

- First, clean the surface of the object to be sprayed (pay attention to whether or not to paint off, which is the key):Remove rust stains, oil and so on, when spraying, the nozzle and spray the best distance is 20cm, should be two times forming, first thin spray again, dry, and then spray second times, this is more uniform, and not easy to hang

- Q: What's the difference between the fastener type steel pipe scaffold, the floor type steel pipe scaffold and the overhanging type steel pipe scaffold?

- It is made up of steel pipe, fastener, base, foot board, safety net and so onSteel pipe rod: generally there are two kinds, an outer diameter 48mm, wall thickness 3.5mm; another kind of outer diameter 51mm, wall thickness 3mm; according to its location and function is different, can be divided into vertical pole, horizontal rod, sweeping rod, etc..Fasteners: fastener is the connection between the steel tube and steel tube, which has three forms, namely the right angle fastener, rotating fastener, butt joint fastener: rectangular fastener for connecting the two vertical pipes, it depends on the friction between the fastener and the steel pipe to transfer load. Swivel fastener: used for connecting two steel tubes intersecting at any angle.

- Q: Are metal spiral tubes the same as metal bellows?

- The spiral pipe is mainly used in the pipeline of petroleum and natural gas, and its specifications are indicated by outer diameter * wall thickness.

- Q: Can steel pipes be used for underground power transmission?

- Yes, steel pipes can be used for underground power transmission. Steel pipes are commonly used for underground power transmission due to their durability, strength, and resistance to corrosion. They provide a reliable and secure conduit for transmitting power underground while protecting the electrical cables from external elements.

- Q: What are the different pipe fittings used with steel pipes?

- Some common pipe fittings used with steel pipes include couplings, elbows, tees, unions, reducers, and caps.

1. Manufacturer Overview

| Location | Shanghai China |

| Year Established | 1999 |

| Annual Output Value | Above Thirty Million RMB |

| Main Markets | Main land;Middle East; Southeast Asia |

| Company Certifications | ISO 9001:2010;API 5L |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Baoshan |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 300-500 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 30,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Oil Casing and Casing Pipe API-5CT,J/K55, N80, L80/P110

- Loading Port:

- Baoshan Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50MT m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords