SSAW Welded Steel Pipes API SEPC 5L API SPEC 5CT ASTM A53

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50MT m.t.

- Supply Capability:

- based on order m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Specification of SSAW Welded Steel Pipes API SPEC 5CT ASTM A53 ASTM A53

1)Application: It is widely applied to line pipe in oil and sewage transportation , and it is used in Low pressure liquid and gassy transportation and it is also good Structure pipe in building and bridge field.

2)Standard: API SPEC 5L, API SPEC 5CT, ASTM A53, GB/T9700.1

3)Steel Grade: API SPEC 5L: B, X42, X46, X52, X56, X60, X65; API SPEC 5CT: J55, K55, N80, L80-1;ASTM A53: A, B, C; GB/T9700.1:L242、L290、L320、L360、L390、L415、L450

2. Sizes of SSAW Welded Steel Pipes API SPEC 5CT ASTM A53 ASTM A53

OD | WT | ||||||||

Noninal Pipe size Inches | MM | 10 | 20 | 30 | STD | 40 | 60 | XS | 80 |

12 | 323.90 |

| 6.35 | 8.38 | 9.53 | 10.31 | 14.27 | 12.70 | 17.48 |

14 | 355.60 | 6.35 | 7.92 | 9.53 | 9.53 | 11.13 | 15.09 | 12.70 | 19.05 |

16 | 406.40 | 6.35 | 7.92 | 9.53 | 9.53 | 12.7 | 16.66 | 12.70 | 21.44 |

18 | 457.00 | 6.35 | 7.92 | 11.13 | 9.53 | 14.27 | 19.05 | 12.70 | 23.88 |

20 | 508.00 | 6.35 | 9.53 | 12.7 | 9.53 | 15.09 | 20.62 | 12.70 | 26.19 |

22 | 559.00 | 6.35 | 9.53 | 12.7 | 9.53 |

| 22.23 | 12.70 | 28.58 |

24 | 610.00 | 6.35 | 9.53 | 14.27 | 9.53 | 17.48 | 24.61 | 12.70 | 30.96 |

26 | 660.00 | 7.92 | 12.70 |

| 9.53 |

|

| 12.70 |

|

28 | 711.00 | 7.92 | 12.70 | 15.88 | 9.53 |

|

| 12.70 |

|

30 | 762.00 | 7.92 | 12.70 | 15.88 | 9.53 |

|

| 12.70 |

|

32 | 813.00 | 7.92 | 12.70 | 15.88 | 9.53 | 17.48 |

| 12.70 |

|

34 | 864.00 | 7.92 | 12.70 | 15.88 | 9.53 | 17.48 |

| 12.70 |

|

36 | 914.00 | 7.92 | 12.70 | 15.88 | 9.53 | 19.05 |

| 12.70 |

|

38 | 965.00 |

|

|

| 9.53 |

|

| 12.70 |

|

40 | 1016.00 |

|

|

| 9.53 |

|

| 12.70 |

|

42 | 1067.00 |

|

|

| 9.53 |

|

| 12.70 |

|

44 | 1118.00 |

|

|

| 9.53 |

|

| 12.70 |

|

46 | 1168.00 |

|

|

| 9.53 |

|

| 12.70 |

|

48 | 1219.00 |

|

|

| 9.53 |

|

| 12.70 |

|

*Remarks: Besides referred sizes, we also can arrange production based on requirement of costumers.

3. Packing&Delivery

Packing Detail: Bundles with anti-rust painting and with plastic cap

Delivery Time: Within 20-30 days upon receving prepayment or L/C

4. Data Sheet

Standard: API SPEC 5L

Mechanical Properties

Standard | Grade | (MPa) | (MPa) | ||

Yield strength | Tensile Strength | ||||

API SPEC 5L | PSL1 | ||||

B | ≥241 | ≥414 | |||

×42 | ≥290 | ≥414 | |||

×46 | ≥317 | ≥434 | |||

×52 | ≥359 | ≥455 | |||

×56 | ≥386 | ≥490 | |||

×60 | ≥414 | ≥517 | |||

×65 | ≥448 | ≥531 | |||

×70 | ≥483 | ≥565 | |||

PSL2 | |||||

Min | Max | Min | Max | ||

B | 241 | 448 | 441 | 758 | |

×42 | 290 | 496 | 414 | 758 | |

×46 | 317 | 524 | 434 | 758 | |

×52 | 359 | 531 | 455 | 758 | |

×56 | 386 | 544 | 490 | 758 | |

×60 | 414 | 565 |

517 |

758 | |

×65 |

448 |

600 |

531 |

758 | |

×70 |

483 |

621 |

565 | 758 | |

Chemical Composition(%)

Standard |

Grade | C | Mn | P | S | TI | CEV |

Max | Max | Max | Max | Max | Max | ||

API SPEC 5L | PSL1 | ||||||

B | 0.26 | 1.2 | 0.030 | 0.030 | 0.04 |

- | |

×42 | 0.26 | 1.3 | 0.030 | 0.030 | 0.04 | ||

×46,×52,×56,X60 | 0.26 | 1.4 | 0.030 | 0.030 | 0.04 | ||

X65 | 0.26 | 1.45 | 0.030 | 0.030 | 0.06 | ||

X70 | 0.26 | 1.65 | 0.030 | 0.030 | 0.06 | ||

PSL2 | |||||||

B | 0.22 | 1.20 | 0.025 | 0.015 | 0.04 |

0.43 | |

×42 | 0.22 | 1.30 | 0.025 | 0.015 | 0.04 | ||

×46,×52,×56, X60 | 0.22 | 1.40 | 0.025 | 0.015 | 0.04 | ||

X65 | 0.22 | 1.45 | 0.025 | 0.015 | 0.06 | ||

X70 | 0.22 | 1.65 | 0.025 | 0.015 | 0.06 | ||

Standard: GB/9711.1

Mechanical Properties

Standard | Grade | (MPa) | (MPa) | Min(%) |

Yield strength | Tensile Strength | Elongation | ||

GB/T9711.1 | L245 | ≥245 | ≥415 | 21 |

L290 | ≥290 | ≥415 | 21 | |

L320 | ≥320 | ≥435 | 20 | |

L360 | ≥360 | ≥460 | 19 | |

L390 | ≥390 | ≥490 | 18 | |

L415 | ≥415 | ≥520 | 17 | |

L450 | ≥450 | ≥535 | 17 | |

L485 | ≥485 | ≥570 | 17 |

Chemical Composition(%)

Standard | Grade | C | Mn | P | S |

Max | Max | Max | Max | ||

GB/T9711.1 | L245 | 0.26 | 0.15 | 0.030 | 0.030 |

L290 | 0.28 | 1.25 | 0.030 | 0.030 | |

L320, L360 | 0.30 | 1.25 | 0.030 | 0.030 | |

L390, L415 | 0.26 | 1.35 | 0.030 | 0.030 | |

L450 | 0.26 | 1.40 | 0.030 | 0.030 | |

L485 | 0.23 | 1.60 | 0.025 | 0.030 |

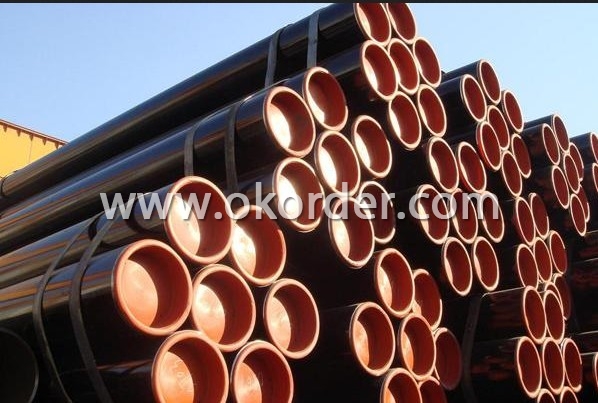

5. Products Showroom

- Q: What is the outer diameter and wall thickness of the welded steel pipe of national standard DN250?

- DN (nominal diameter) 250 is generally the industry said 273, welded steel pipe (spiral steel pipe) thickness is generally between 6-8mm, more common.

- Q: How to descaling galvanized steel pipe?

- Is red rust or white rust, red rust is the base material rust, white rust is Zinc Coating Rust

- Q: What are the safety considerations when working with steel pipes?

- When working with steel pipes, safety considerations include wearing appropriate personal protective equipment such as gloves, safety glasses, and steel-toed boots to prevent injuries. It is essential to handle and lift steel pipes using proper techniques and equipment to avoid strains and falls. Ensuring a clean and organized work area, as well as securing pipes to prevent rolling or tipping, reduces the risk of accidents. Additionally, workers should be cautious of sharp edges and ensure proper ventilation when working with welding or cutting tools to minimize the risk of fires or inhalation hazards.

- Q: How are steel pipes used in the manufacturing of pressure vessels?

- Steel pipes are commonly used in the manufacturing of pressure vessels as they provide the necessary strength and durability to withstand high internal pressure. These pipes are welded or seamless and are often used as the main structural component of the vessel. They allow for the efficient flow of fluids or gases within the vessel and provide a reliable and secure containment system for various industrial applications.

- Q: Can steel pipes be used for hydronic heating systems?

- Yes, steel pipes can be used for hydronic heating systems. Steel pipes are commonly used in hydronic heating systems due to their durability, strength, and ability to withstand high temperatures and pressures. They are also resistant to corrosion, making them suitable for long-term use in these systems.

- Q: What is the fatigue strength of steel pipes?

- The fatigue strength of steel pipes refers to their ability to withstand repeated cyclic loading without experiencing failure. It is a critical characteristic for pipes that are subject to dynamic or fluctuating loads, such as those used in the oil and gas industry, transportation infrastructure, or industrial applications. The fatigue strength of steel pipes can vary depending on several factors, including the steel grade, pipe dimensions, manufacturing process, surface conditions, and environmental factors. Steel pipes with higher tensile strength and toughness generally exhibit better fatigue resistance. The fatigue strength is typically determined through fatigue testing, which involves subjecting the pipes to cyclic loading until failure occurs. The results are then used to establish a fatigue curve or S-N curve, which represents the relationship between the applied stress amplitude and the number of cycles to failure. The fatigue strength is commonly expressed as the stress amplitude required to cause failure after a specific number of cycles, such as the stress amplitude at 10 million cycles (S-N10^7). It is important to note that fatigue strength is influenced by other factors, such as mean stress, surface finish, and loading frequency, which may need to be considered in specific applications. Overall, the fatigue strength of steel pipes is a crucial factor to consider in engineering design and maintenance, as it helps ensure the long-term integrity and reliability of the pipes under cyclic loading conditions.

- Q: What are steel pipes?

- Steel pipes are hollow cylindrical tubes made from steel, which are mainly used for transporting fluids and gases in various industries such as oil and gas, construction, and plumbing. They are known for their strength, durability, and resistance to corrosion, making them an essential component in infrastructure and industrial applications.

- Q: Seamless steel pipe and welded pipe what is the difference?

- Identification method: see the inside of the pipe, because the external, will deal with the welded pipe is inside a gap, you can see some, some, is not easy to see, you can slowly by hand touch, or see the specifications are relatively thin, welded pipe

- Q: How are steel pipes used in structural applications?

- Steel pipes are commonly used in structural applications due to their high strength and durability. They are used for various purposes such as supporting structures, transferring loads, and providing stability. Steel pipes can be used as columns, beams, or trusses in buildings, bridges, and other structures. They are also used for underground water and gas pipelines, as well as in industrial and manufacturing facilities. Overall, steel pipes play a crucial role in providing stability and strength to structural applications.

- Q: What is the typical lifespan of steel pipes?

- The lifespan of steel pipes can differ based on several factors, including the steel quality, environmental conditions, and pipe maintenance and usage. On average, steel pipes typically last between 50 and 100 years. However, by installing them correctly, conducting regular inspections, and maintaining them appropriately, steel pipes can often surpass this lifespan and offer dependable service for many decades. It is worth noting that corrosion, erosion, and external damage can affect the longevity of steel pipes. Therefore, it is essential to implement preventive measures and carry out necessary repairs to guarantee their durability.

1. Manufacturer Overview

| Location | Tianjin, China |

| Year Established | 2001 |

| Annual Output Value | 500,000Tons |

| Main Markets | Southeast Asia; Middle East; Oceania; Americas; Europe; Africa;etc. |

| Company Certifications | API 5L;API 5CT;ISO9001:2008 GB/T 19001-2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin;Qingdao |

| Export Percentage | 50% - 60% |

| No.of Employees in Trade Department | 1000-1100 People |

| Language Spoken: | English; Chinese; Spanish |

| b) Factory Information | |

| Factory Size: | Above 150,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

SSAW Welded Steel Pipes API SEPC 5L API SPEC 5CT ASTM A53

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50MT m.t.

- Supply Capability:

- based on order m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords