Dental Floss Available Wholesale OEM Individually Floss Mint Waxed 50yds

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 box

- Supply Capability:

- 100000 box/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Dental Floss Durable Portable Hygienic Cleanliness Restaurant Household Flossing

Brand: OEM/Ok Floss

Floss material:TPFE

Floss length:50m/OEM

Wax:Import germany wax/american wax/bee wax/candelilla wax/customized wax

Flavor:Mint / green tea / lemon / peach / fruit / aloe / gin

ColorFloss: original color

Floss original color:Individual bulk PP box/as customized

Applications:Family,Hotel,Travel,Supermarket

Delivery:By sea,By air,By express.

Lead time:20-30days

Soft tape to ace the tight space

No break, no shred floss

Helps remove plaque between teeth

Helps prevent gingivitis between teeth

Unique handle design, makes it easy and comfortable to floss. Removes trapped food debris.

Extra bristled pick for hard to get bits,even gets behind hard-to-reach molars.

Gently slides smooth between tight teeth. Freshen breath with flavor.

Recommends you use OK flosser after every meal and snack to have a fresher, cleaner mouth. For a completely daily clean, use with a OK flosser to easily reach back teeth.

Why we need use dental floss??

Because it can reduce your chances of 60% ofadjacent dental caries and 70% of periodontal disease.

It allows you to have a healthy tooth of your own at the age of 80.

Flossing your teeth in the right way will remove food particles and growing plaque from spots

where your toothbrush can’t reach, generally between your teeth and under the gumline.

FAQ

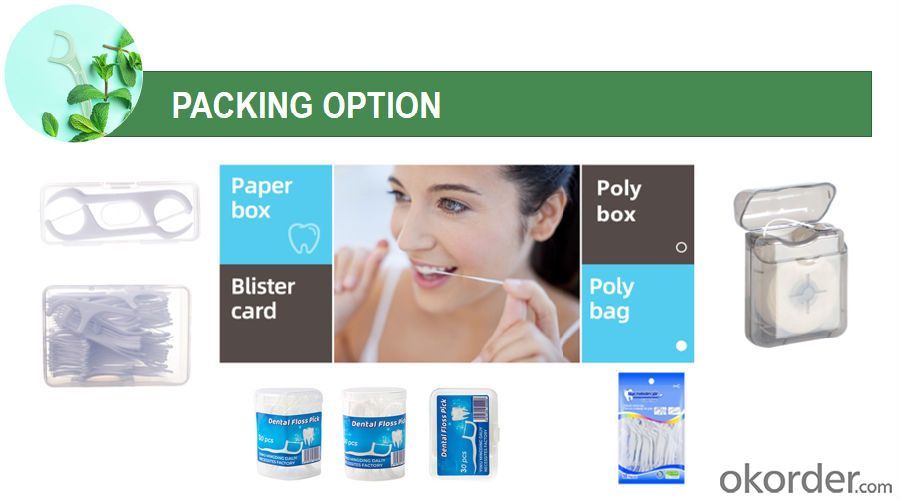

Q: Can you accept OEMcan make your customize can make your customized brand and design blister card, inner box and master carton, and also pack as per your request.

2. Q: Where can I put my logo?

A: We can print your logo on the sticker, blister card, inner box and master carton.

3. Q: What are your MOQ?

A: Blister card packing: 10000 pcs/item.

Bulk packing: 5000 pcs/item.

4. Q: How can I get Samples?

A: Samples are free, while the shipping cost to be collected.

5. Q: What are your terms of payment?

A: 1) T/T(30% in advance, the balance by the copy of B/L).

2)For small order less than USD 3000, in order to save bank commision for both of us, we need 100% in advance.

6. Q: How long is the delivery time?

A: For the MOQ, the leading time is about 20-30 days.

Suggested use

Directions for flossing: While holding the handle, gently guide the floss between your teeth using a zig-zag motion. Move floss away from the gumline in a gentle back and forth, up and down motion alongside each tooth to remove food particles and plaque. Rinse floss as needed and repeat for each tooth.

Warnings

Adult supervision recommended under age 10.

- Q: Can medical plastic be used for long-term implantable devices?

- Yes, medical plastic can be used for long-term implantable devices. Medical-grade plastics, such as polyethylene, polyurethane, and silicone, are commonly used in the manufacturing of various long-term implantable medical devices. These materials are biocompatible, durable, and resistant to degradation, making them suitable for extended periods of implantation within the human body. However, specific factors such as device design, material selection, and patient-specific considerations should be taken into account to ensure the safety and efficacy of the implantable device.

- Q: Can medical alcohol be bottled in plastic?

- Plastic bottles have special, non dedicated, non dedicated, for alcohol, corrosion resistance is relatively poor, professional resistance to strong, so recommend Louzhu use glass

- Q: Will plastic containers release harmful substances? I've been in the car for a month and the temperature is above 30 a day. Can I still eat it?

- General medical packaging plastic products, or the strict use of polyethylene standard materials governance, generally harmless.

- Q: Are there any limitations to the use of medical plastics?

- Yes, there are limitations to the use of medical plastics. Some limitations include the potential for leaching of chemicals into the body, the risk of allergic reactions or sensitivities, and the inability to withstand extreme temperatures or certain sterilization methods. Additionally, the disposal and environmental impact of medical plastics is a concern.

- Q: What are the advancements in 3D printing of medical plastic?

- Advancements in 3D printing of medical plastics have revolutionized the healthcare industry. These include improved biocompatible materials, enhanced precision and accuracy in printing complex anatomical structures, and the development of personalized medical devices and implants. Additionally, the ability to rapidly prototype and customize medical tools and models has significantly improved surgical planning and training, ultimately leading to better patient outcomes.

- Q: What safety regulations apply to medical plastic?

- Safety regulations that apply to medical plastic include guidelines set by regulatory bodies such as the Food and Drug Administration (FDA) in the United States and the European Medicines Agency (EMA) in the European Union. These regulations ensure that medical plastics are tested, certified, and manufactured in compliance with strict quality and safety standards. They cover aspects such as biocompatibility, sterility, chemical resistance, and durability to ensure patient safety and the effectiveness of medical devices and packaging.

- Q: What are the considerations for ensuring the transparency and clarity of medical plastic materials?

- There are several considerations for ensuring the transparency and clarity of medical plastic materials. Firstly, selection of high-quality raw materials is crucial to ensure optimal clarity. This includes choosing plastics with low levels of impurities and additives that can affect transparency. Secondly, the manufacturing process must be carefully controlled to minimize any potential defects or imperfections that may impair clarity. This involves maintaining precise temperature and pressure conditions during molding or extrusion. Additionally, proper post-processing techniques such as polishing or annealing may be employed to enhance transparency further. Lastly, regular quality control measures should be implemented to ensure consistency in transparency and clarity throughout the production and storage of medical plastic materials.

- Q: Can medical plastics be used in prosthetics?

- Yes, medical plastics can be used in prosthetics. Medical-grade plastics are commonly used in the manufacturing of prosthetic limbs and other medical devices due to their durability, lightweight nature, and biocompatibility. These plastics can be customized to create prosthetics that are comfortable, functional, and aesthetically appealing to enhance the quality of life for individuals with limb loss or impairment.

- Q: What are the regulations for the use of medical plastic in contact with blood?

- The regulations for the use of medical plastic in contact with blood are primarily outlined by regulatory bodies such as the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA). These regulations aim to ensure the safety and effectiveness of medical devices that come into contact with blood. They typically involve rigorous testing and evaluation processes to assess biocompatibility, sterility, and potential risks associated with the use of medical plastics. Compliance with these regulations is crucial to ensure the protection of patients and to maintain the quality and integrity of medical devices used in healthcare settings.

- Q: Can medical plastic leach harmful substances into the body?

- Yes, medical plastic can potentially leach harmful substances into the body.

Send your message to us

Dental Floss Available Wholesale OEM Individually Floss Mint Waxed 50yds

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 box

- Supply Capability:

- 100000 box/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches