Dental Floss Various Flavors Hygienic Cleanliness Flossing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 box

- Supply Capability:

- 100000 box/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Dental Floss Various Flavors Hygienic Cleanliness Flossing

| Brand | OEM/Ok Floss |

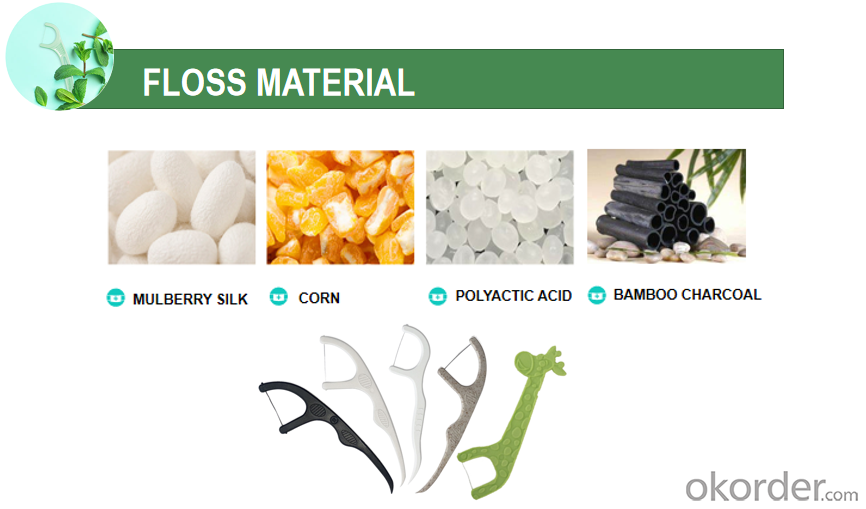

| Floss material | Charcoal ,UHMWPE ,nylon |

| Floss length | 7.4*2.2cm/25-30M/OEM |

| Wax | Import germany wax/american wax/bee wax/candelilla wax/customized wax |

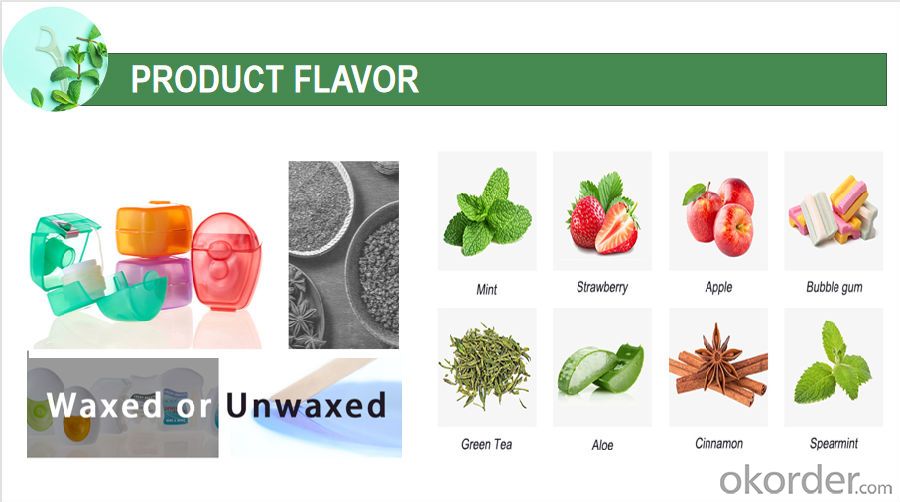

| Flavor | Mint / green tea / lemon / peach / fruit / aloe / gin |

| Color | Floss original color |

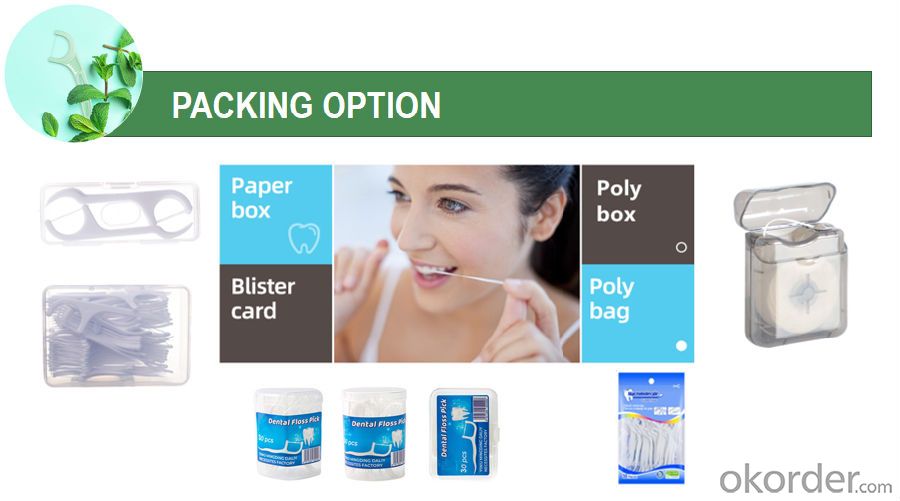

| Floss original color | Individual bulk PP bag/individual paper box/as customized |

| Applications | Family,Hotel,Travel,Supermarket |

| Delivery | By sea,By air,By express. |

| Lead time | 20-30days |

Description

Soft tape to ace the tight space

No break, no shred floss

Helps remove plaque between teeth

Helps prevent gingivitis between teeth

Unique handle design, makes it easy and comfortable to floss. Removes trapped food debris.

Extra bristled pick for hard to get bits,even gets behind hard-to-reach molars.

Gently slides smooth between tight teeth. Freshen breath with flavor.

Recommends you use OK flosser after every meal and snack to have a fresher, cleaner mouth. For a completely daily clean, use with a OK flosser to easily reach back teeth.

Why we need use dental floss??

Because it can reduce your chances of 60% of

adjacent dental caries and 70% of periodontal

disease.

It allows you to have a healthy tooth of your own at

the age of 80.

Flossing your teeth in the right way will remove

food particles and growing plaque from spots

where your toothbrush can’t reach, generally

between your teeth and under the gumline.

400D UHMWPE EXTRA STRONG FLOSS

Thin,strong,high resilience non-braching.Using supper smooth food

grade.UHMWPE floss ,not easy to stretch shred ,or break.

HIPS HANDLE

HIPS HANDLE

Food grade PS material,safe,solid,Antiskid.Comfortable to hold for precise cleanig.

TOOTHPICK TAIL

Pointed-end remove foof residue effectivelly.Using food grade material,special

curved design toothpick,better for deep cleanig.

Made with super protected pick that tuffloss that doesn’t stretch,shred or break.

Protested pick that floss away for use.

Suggested use

Directions for flossing: While holding the handle, gently guide the floss between your teeth using a zig-zag motion. Move floss away from the gumline in a gentle back and forth, up and down motion alongside each tooth to remove food particles and plaque. Rinse floss as needed and repeat for each tooth.

Warnings

Adult supervision recommended under age 10.

FAQ

Q: Can you accept OEMcan make your customize can make your customized brand and design blister card, inner box and master carton, and also pack as per your request.

2. Q: Where can I put my logo?

A: We can print your logo on the sticker, blister card, inner box and master carton.

3. Q: What are your MOQ?

A: Blister card packing: 10000 pcs/item.

Bulk packing: 5000 pcs/item.

4. Q: How can I get Samples?

A: Samples are free, while the shipping cost to be collected.

5. Q: What are your terms of payment?

A: 1) T/T(30% in advance, the balance by the copy of B/L).

2)For small order less than USD 3000, in order to save bank commision for both of us, we need 100% in advance.

6. Q: How long is the delivery time?

A: For the MOQ, the leading time is about 20-30 days.

- Q: How is medical plastic used in ophthalmic implants?

- Medical plastic is used in ophthalmic implants to create safe and efficient devices that are implanted in the eye to treat various conditions. These implants, typically made from biocompatible materials such as silicone or polymethyl methacrylate (PMMA), are used in procedures like cataract surgery, intraocular lens replacement, and glaucoma treatment. Medical plastic provides the necessary flexibility, transparency, and compatibility with the eye's tissues, ensuring successful implantation and long-term functionality.

- Q: Can medical plastics be used in neurosurgical applications?

- Yes, medical plastics can be used in neurosurgical applications. They are often used in the manufacturing of various neurosurgical devices and implants such as catheters, shunts, and cranial implants. These medical plastics are chosen for their biocompatibility, durability, and ability to withstand sterilization processes. They play a crucial role in enhancing patient safety and improving surgical outcomes in neurosurgery.

- Q: How are medical plastics used in wound closure devices?

- Medical plastics are commonly used in wound closure devices such as sutures, staples, and adhesive strips. They provide strength, flexibility, and biocompatibility, allowing for effective wound closure and healing. These plastics are specifically designed to be sterile, easy to handle, and safe for use within the human body.

- Q: What are the considerations for using medical plastic in drug reconstitution devices?

- When considering the use of medical plastic in drug reconstitution devices, several factors need to be taken into account. First and foremost, the plastic material used should be compatible with the drug being reconstituted to ensure there is no chemical interaction or leaching of harmful substances into the medication. The second consideration is the physical properties of the plastic, such as its strength, durability, flexibility, and transparency. The plastic should be able to withstand the physical stresses involved in the reconstitution process, including shaking or mixing, without breaking or degrading. Additionally, it should be transparent or translucent enough to allow for accurate measurement and observation of the reconstituted drug. Another important aspect to consider is the biocompatibility of the plastic. The material should be non-toxic and non-irritating to human tissues, as the reconstituted drug may come into contact with the patient's body during administration. Ensuring that the plastic is free from any potential allergens or sensitizing agents is crucial to prevent adverse reactions. Furthermore, the manufacturing process and quality control of the medical plastic should be carefully evaluated. The material should be produced in accordance with strict standards and regulations to ensure consistency, purity, and absence of contaminants. Thorough testing and validation should also be conducted to assess the plastic's compatibility and performance with the specific drug reconstitution device. Overall, the considerations for using medical plastic in drug reconstitution devices revolve around compatibility with the drug, physical properties, biocompatibility, and adherence to regulatory requirements. By carefully evaluating and addressing these factors, the safe and effective use of medical plastic in drug reconstitution devices can be assured.

- Q: What are the considerations for preventing the formation of stress cracks in medical plastic products?

- There are several key considerations for preventing the formation of stress cracks in medical plastic products. Firstly, selecting the appropriate plastic material with high resistance to stress cracking is crucial. This involves understanding the specific environmental conditions the product will be exposed to, such as temperature, humidity, and chemical exposure. Secondly, proper design and manufacturing techniques should be employed to minimize stress concentration points in the product. This includes avoiding sharp corners or abrupt changes in geometry that can lead to stress concentration and eventual cracking. Thirdly, careful handling and storage of the plastic products is essential. Excessive bending or mishandling during transportation can induce stress on the material, increasing the risk of stress cracks. Additionally, regular quality control checks should be implemented during the manufacturing process to identify any defects or weaknesses in the plastic products that could potentially lead to stress cracks. Overall, a combination of material selection, design considerations, proper handling, and quality control measures are crucial in preventing the formation of stress cracks in medical plastic products.

- Q: Can medical plastics be used for reproductive medicine or fertility treatments?

- Yes, medical plastics can be used for reproductive medicine or fertility treatments. They are commonly utilized in various applications such as in vitro fertilization (IVF) procedures, embryo transfer catheters, and sperm and egg donation storage containers. Medical plastics offer biocompatibility, sterility, and flexibility, making them suitable for use in reproductive medicine and fertility treatments.

- Q: What are the considerations for using medical plastic in bioimplants?

- There are several important considerations when using medical plastic in bioimplants. Firstly, biocompatibility is crucial to ensure that the material does not cause any adverse reactions or harm to the patient's body. Additionally, the plastic must possess appropriate mechanical properties, such as strength and flexibility, to withstand the physiological conditions and stresses within the body. It is also important to consider the sterilization methods that can be applied to the plastic without compromising its structural integrity. Furthermore, the degradation rate of the plastic should be taken into account to ensure that it aligns with the desired lifespan of the implant. Lastly, the cost-effectiveness and availability of the medical plastic should be considered, as it will impact the overall viability and accessibility of the bioimplant.

- Q: Is it made of plastic, titanium or metal titanium?

- If the medical institution and its medical personnel are at fault, the medical institution shall bear the liability for compensation when the patient is injured in the diagnosis and treatment.

- Q: How do medical plastics contribute to the field of rehabilitation medicine?

- Medical plastics contribute to the field of rehabilitation medicine by providing innovative and customizable solutions for patients. These plastics are used to create orthotic and prosthetic devices, ensuring the perfect fit and comfort for individuals with mobility impairments. Additionally, medical plastics are used in the development of rehabilitation equipment such as wheelchairs, walkers, and exercise devices, enhancing functionality and improving patient outcomes.

- Q: Are there any concerns about the long-term safety of medical plastics?

- Yes, there are concerns about the long-term safety of medical plastics. While medical plastics have revolutionized healthcare in many ways, there are ongoing debates and studies regarding their potential health risks. Some concerns include the leaching of harmful chemicals into the body, the potential for bacterial contamination, and the environmental impact of plastic waste. Research is needed to better understand the long-term effects of medical plastics on human health and to develop safer alternatives if necessary.

Send your message to us

Dental Floss Various Flavors Hygienic Cleanliness Flossing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 box

- Supply Capability:

- 100000 box/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches