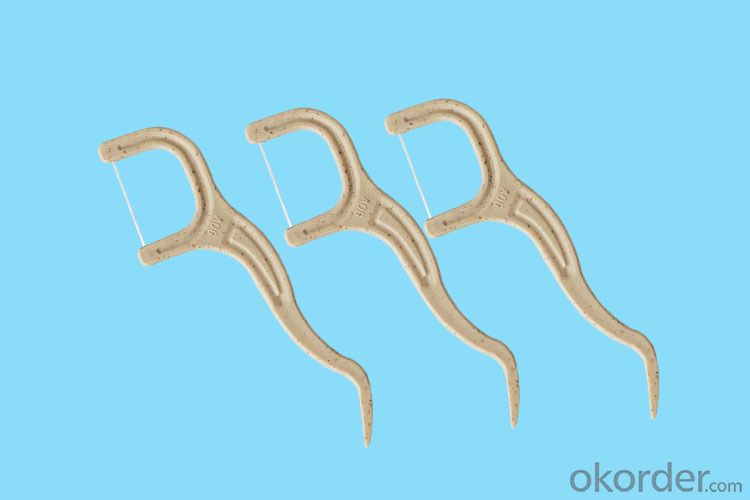

Dental Floss Pick Wheat Straw Eco Friendly Natural Fresh Up Floss

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 bag

- Supply Capability:

- 100000 bag/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

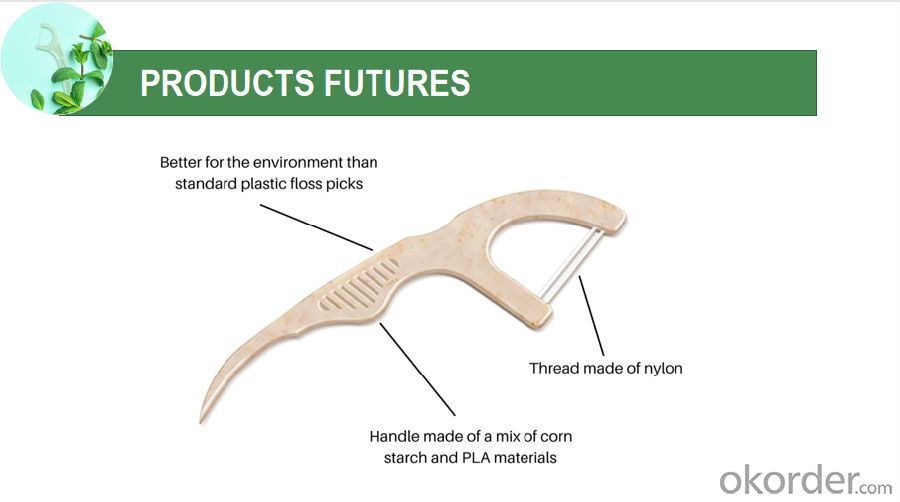

Dental Floss Pick Wheat Straw Eco Friendly Natural Fresh Up Floss

| Brand | OEM/Ok Floss |

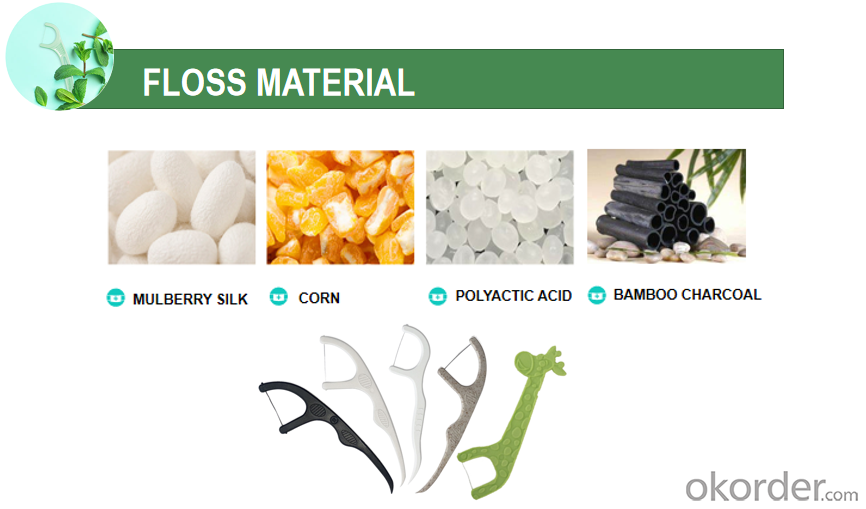

| Floss material | UHMWPE/PTFE+Straw |

| Floss length | 7.4*2.2cm/OEM |

| Wax | Import germany wax/american wax/bee wax/candelilla wax/customized wax |

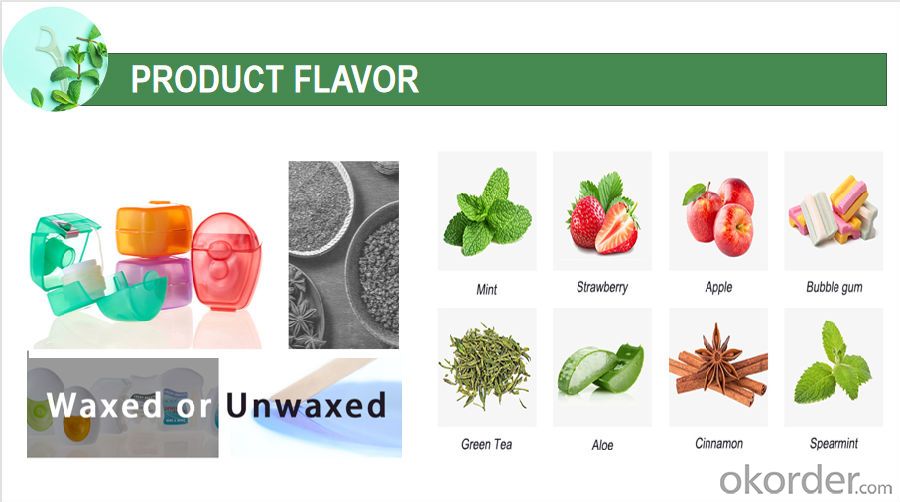

| Flavor | Mint / green tea / lemon / peach / fruit / aloe / gin |

| Color | Floss original color |

| Floss original color | Individual bulk PP bag/individual paper box/as customized |

| Applications | Family,Hotel,Travel,Supermarket |

| Delivery | By sea,By air,By express. |

| Lead time | 20-30days |

Soft tape to ace the tight space

No break, no shred floss

Helps remove plaque between teeth

Helps prevent gingivitis between teeth

Unique handle design, makes it easy and comfortable to floss. Removes trapped food debris.

Extra bristled pick for hard to get bits,even gets behind hard-to-reach molars.

Gently slides smooth between tight teeth. Freshen breath with flavor.

Recommends you use OK flosser after every meal and snack to have a fresher, cleaner mouth. For a completely daily clean, use with a OK flosser to easily reach back teeth.

Why we need use dental floss??

Because it can reduce your chances of 60% of

adjacent dental caries and 70% of periodontal

disease.

It allows you to have a healthy tooth of your own at

the age of 80.

Flossing your teeth in the right way will remove

food particles and growing plaque from spots

where your toothbrush can’t reach, generally

between your teeth and under the gumline.

Suggested use

Directions for flossing: While holding the handle, gently guide the floss between your teeth using a zig-zag motion. Move floss away from the gumline in a gentle back and forth, up and down motion alongside each tooth to remove food particles and plaque. Rinse floss as needed and repeat for each tooth.

Warnings

Adult supervision recommended under age 10.

FAQ

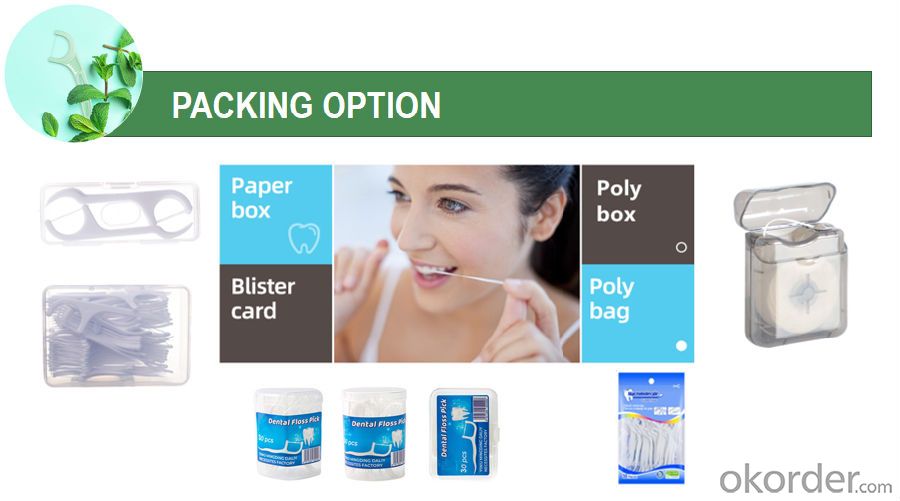

Q: Can you accept OEM make?

A: Sure.We can make your customized brand and design blister card, inner box and master carton, and also pack as per your request.

2. Q: Where can I put my logo?

A: We can print your logo on the sticker, blister card, inner box and master carton.

3. Q: What are your MOQ?

A: Blister card packing: 10000 pcs/item.

Bulk packing: 5000 pcs/item.

4. Q: How can I get Samples?

A: Samples are free, while the shipping cost to be collected.

5. Q: What are your terms of payment?

A: 1) T/T(30% in advance, the balance by the copy of B/L).

2)For small order less than USD 3000, in order to save bank commision for both of us, we need 100% in advance.

6. Q: How long is the delivery time?

A: For the MOQ, the leading time is about 20-30 days.

- Q: Is resin material PBT harmful to the body?

- Generally speaking, as long as the resin does not enter the skin, mouth, eyes and other bodies, its toxicity is still very small. If the room is only a small part of the resin product decoration decoration, do not have harm.

- Q: Size of bubble pot

- Specifications from 0.25L--220LOpen and close plastic bucket and 1000L plastic barrel. Can be used for articles to hold or transport turnover. The maximum capacity of plastic bucket capacity current rotational molding production can reach 50 tons.Some products can be used for hot filling, and the general temperature should be no more than 60 degrees centigrade. Hot filling, etc. should be contained objects and the full cooling down to room temperature in order to shut the lid and stacking. Weather resistance zero above 60 degrees - 40 degrees below zero, good performance.

- Q: Are there any potential risks associated with the accumulation of bacteria on medical plastics?

- Yes, there are potential risks associated with the accumulation of bacteria on medical plastics. Bacteria can multiply and form biofilms, which can make it difficult to effectively clean and disinfect the surfaces, increasing the chances of infection transmission. Additionally, some bacteria have the ability to develop antibiotic resistance, posing a threat to patient safety and treatment efficacy. Regular cleaning and proper disinfection protocols are crucial to mitigate these risks.

- Q: Can medical plastics be made conductive?

- Yes, medical plastics can be made conductive by incorporating conductive additives or by using conductive polymers during the manufacturing process.

- Q: What are the factors affecting the biocompatibility of medical plastic?

- The factors affecting the biocompatibility of medical plastic include the chemical composition of the plastic material, its physical properties such as surface roughness and porosity, the presence of additives or impurities, and the body's immune response to the plastic. Additionally, factors such as sterilization methods, manufacturing processes, and the duration of contact between the plastic and the body can also influence its biocompatibility.

- Q: How is medical plastic used in orthopedic implants?

- Medical plastic is used in orthopedic implants to provide structural support, flexibility, and biocompatibility. It is commonly used in the manufacturing of joint replacements, bone plates, screws, and other devices. The plastic used in these implants is designed to mimic the properties of natural bone, allowing for better integration with the surrounding tissues and promoting healing. Additionally, medical plastic is lightweight and durable, making it an ideal material for orthopedic implants that need to withstand the mechanical stresses of the body.

- Q: How can plastic cloth be glued to plastic steel windows?

- The water between the polymers does not evaporate easily. This is why the thicker the film, the worse the adhesive effect on the adhesive". The amount of coating is too large, the glue is big, it is the filling action, not the adhesive action. The adhesive between the objects is not the adhesive force of the glue, but the cohesive force of the glue". If it is not water soluble, the principle is much the same, that is, instead of water with other solvents.

- Q: When infusion, why does infusion bottle (plastic) become deformed?

- In the infusion, there is a needle in the bottle, but he is a double mouth, one is used to drain the liquid in the bottle, and the other is that the liquid in the bottle is lost and the pressure is reduced into the air to supplement the pressure balance in it.

- Q: What are the commonly used medical plastics categories?

- The utility model has the advantages of low cost, no sterilization and repeated use, and is suitable for being used as the raw material for the production of disposable medical instruments;

- Q: Can medical plastics be used for long-term implantation?

- Yes, medical plastics can be used for long-term implantation. They are often utilized in various medical devices and implants such as joint replacements, cardiac pacemakers, and dental implants. Medical-grade plastics are biocompatible, meaning they do not cause adverse reactions when in contact with the human body. Additionally, they possess excellent mechanical properties, durability, and resistance to corrosion, making them suitable for long-term implantation.

Send your message to us

Dental Floss Pick Wheat Straw Eco Friendly Natural Fresh Up Floss

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 bag

- Supply Capability:

- 100000 bag/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords