Correcting smell dental floss suitable for children

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

No break, no shred floss

Helps remove plaque between teeth

Helps prevent gingivitis between teeth

Unique handle design, makes it easy and comfortable to floss. Removes trapped food debris.

Extra bristled pick for hard to get bits,even gets behind hard-to-reach molars.

Gently slides smooth between tight teeth. Freshen breath with flavor.

Recommends you use OK flosser after every meal and snack to have a fresher, cleaner mouth. For a completely daily clean, use with a OK flosser to easily reach back teeth.

Correcting smell dental floss suitable for children

| Brand | Ok Floss |

| Floss material | UHMWPE |

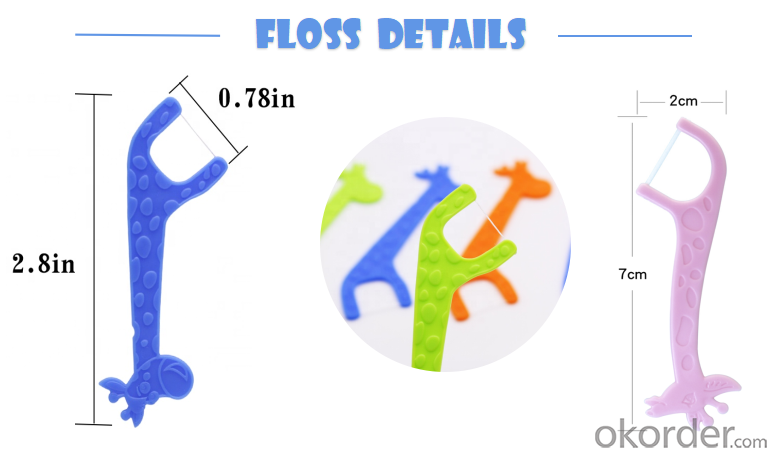

| Size | Length: 7.5cm Width:2.0cm Thickness: 0.2cm U-Slot: 2.0cm Floss: 1.2cm |

| Wax | Import germany wax/american wax/bee wax/candelilla wax/customized wax |

| Flavor | Mint / green tea /fruit |

| Color | white,yellow,orange |

| Floss original color | Individual bulk PP bag/individual paper box/as customized |

| Applications | Family,Restaurant |

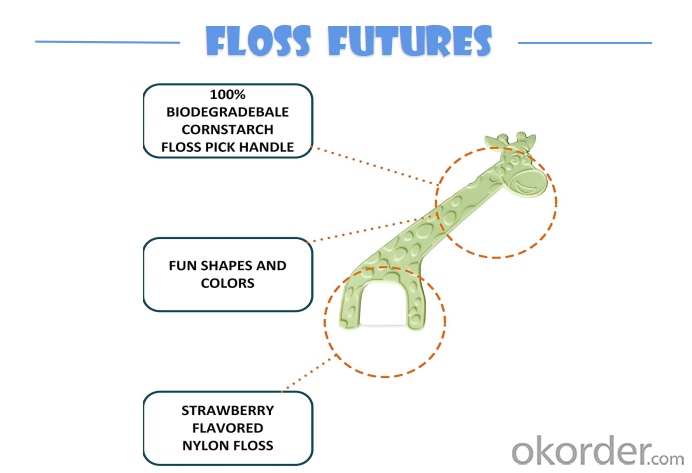

| Shape | Bear,Giraffe |

| Lead time | 20-30days |

Suggested use

Directions for flossing: While holding the handle, gently guide the floss between your teeth using a zig-zag motion. Move floss away from the gumline in a gentle back and forth, up and down motion alongside each tooth to remove food particles and plaque. Rinse floss as needed and repeat for each tooth.

Warnings

Adult supervision recommended under age 10.

FAQ

Q: Can you accept OEM make?

Q: Can you accept OEM make?

A: Sure.We can make your customized brand and design blister card, inner box and master carton, and also pack as per your request.

2. Q: Where can I put my logo?

A: We can print your logo on the sticker, blister card, inner box and master carton.

3. Q: What are your MOQ?

A: Blister card packing: 10000 pcs/item.

Bulk packing: 5000 pcs/item.

4. Q: How can I get Samples?

A: Samples are free, while the shipping cost to be collected.

5. Q: What are your terms of payment?

A: 1) T/T(30% in advance, the balance by the copy of B/L).

2)For small order less than USD 3000, in order to save bank commision for both of us, we need 100% in advance.

6. Q: How long is the delivery time?

A: For the MOQ, the leading time is about 20-30 days.

- Q: What are the considerations for selecting medical plastic for dental implants?

- When selecting medical plastic for dental implants, there are several important considerations to keep in mind. Firstly, the material should be biocompatible, meaning it does not cause any adverse reactions or allergies in the patient's body. Additionally, the plastic should have high strength and durability to withstand the forces exerted in the oral cavity. It is also crucial for the material to have good aesthetics, blending seamlessly with the natural teeth and gums. Finally, the plastic should be resistant to corrosion and wear, ensuring the longevity and success of the dental implant.

- Q: What are the potential environmental impacts of medical plastics?

- The potential environmental impacts of medical plastics include pollution through improper disposal, non-biodegradability leading to long-term accumulation in landfills and oceans, release of toxic chemicals during production and incineration, and contribution to greenhouse gas emissions and climate change.

- Q: Can medical plastic be safely used in dermatological applications?

- Yes, medical plastic can be safely used in dermatological applications. Medical-grade plastics are specifically designed to be biocompatible, hypoallergenic, and non-toxic, making them suitable for various dermatological procedures and treatments. These plastics provide a sterile and durable solution for medical devices used in dermatology, such as syringes, surgical instruments, and wound dressings. Additionally, medical plastics can be easily molded into different shapes and sizes to meet the specific needs of dermatological applications.

- Q: Why are the plastic foams one grain each? How was it made?

- This is mainly determined by the manufacturing process. It is a mixture of resins and physical foaming agents and other additives that produce small beads of resin beads by suspension polymerization (so they are generally round).

- Q: What are the considerations for using medical plastic in intravenous drug delivery systems?

- There are several key considerations for using medical plastic in intravenous drug delivery systems. Firstly, the plastic material must be biocompatible to ensure it does not cause any adverse reactions or harm to the patient. Additionally, it should be chemically inert to prevent any unwanted interactions between the plastic and the medication. The plastic should also possess good mechanical properties, such as flexibility and strength, to withstand the rigors of use. Furthermore, the plastic should be compatible with sterilization methods to ensure proper hygiene and safety. Lastly, cost-effectiveness and ease of manufacturing are important factors to consider when selecting medical plastic for intravenous drug delivery systems.

- Q: What are the characteristics of electrical plastics? What are the categories?

- This kind of thermoplastic plastics soften when heated, the temperature rises to a certain degree in the molten state, a viscous fluid can flow by means of pressure and mold products, can be made in a certain shape, after cooling can keep the molded shape. Again, the variable soft heating and melting, re plastic molding. In the process of heating and cooling, it has only physical change without chemical change. There are many kinds of plastics, such as PE, PVC, PA, PS, PMMA, ABS, PC, PP and so on.

- Q: Can medical plastics be used in drug delivery systems?

- Yes, medical plastics can be used in drug delivery systems. They are often used to manufacture various components of drug delivery devices, such as syringes, vials, and implantable devices. Medical plastics offer advantages like biocompatibility, durability, and ease of manufacturing, making them suitable for drug delivery applications. Additionally, they can be designed to be sterile, inert, and resistant to chemical interactions, ensuring the safe and effective delivery of medications to patients.

- Q: Are there any concerns about the mechanical strength of medical plastics?

- Yes, there are concerns about the mechanical strength of medical plastics. While medical plastics have numerous advantages such as being lightweight and easily molded, their mechanical strength can sometimes be compromised. This is especially true in applications where the plastic needs to withstand high stress or pressure. To address these concerns, manufacturers and engineers need to carefully select the appropriate type of plastic and design it to meet the specific mechanical requirements of the medical device or component. Regular testing and quality control measures are also crucial to ensure the mechanical strength and reliability of medical plastics in various healthcare settings.

- Q: How do medical plastics contribute to the development of smart medical devices?

- Medical plastics play a crucial role in the development of smart medical devices by providing a range of beneficial properties such as biocompatibility, durability, and flexibility. These plastics are used in various components of smart medical devices, including sensors, microfluidic channels, and implantable devices, enabling advanced functionalities and improved patient care. Additionally, medical plastics allow for miniaturization and integration of electronic components, enhancing the overall performance and portability of smart medical devices.

- Q: What are the most common challenges in manufacturing medical plastics?

- Some of the most common challenges in manufacturing medical plastics include ensuring the materials meet strict regulatory requirements, maintaining consistent quality standards, managing complex supply chains, addressing the need for customization and scalability, and navigating the constantly evolving technological advancements in the field.

Send your message to us

Correcting smell dental floss suitable for children

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords