Children's Safe Flavoring Dental Floss Pick

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 box

- Supply Capability:

- 100000 box/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Children's Safe Flavoring Dental Floss Pick

| Brand: | OEM/Ok Floss |

| Floss material: | UHMWPE,Charcal as customized |

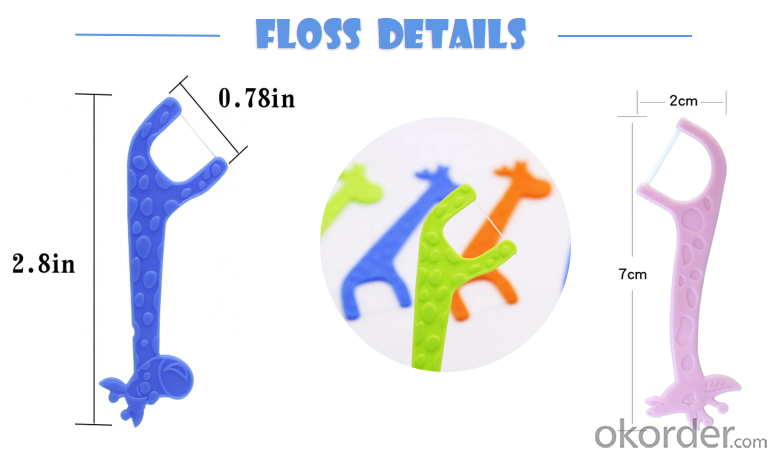

| Size: | Length: 7.5cm Width:2.0cm Thickness: 0.2cm U-Slot: 2.0cm Floss: 1.2cm |

| Wax: | Import germany wax/american wax/bee wax/candelilla wax/customized wax |

| Flavor: | Mint / green tea / lemon / peach / fruit / aloe / gin |

| Color: | Floss original color |

| Floss original color: | Individual bulk PP bag/individual paper box/as customized |

| Applications: | Family,Hotel,Travel,Supermarket |

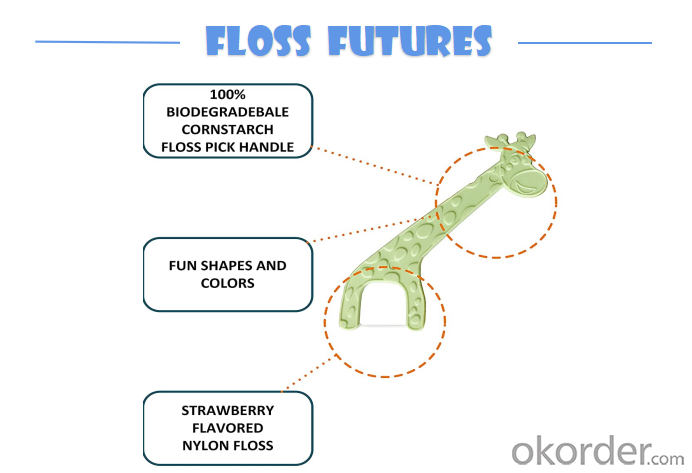

| Shape: | Bear,Giraffe,Cola |

| Lead time: | 20-30days |

Soft tape to ace the tight space

No break, no shred floss

Helps remove plaque between teeth

Helps prevent gingivitis between teeth

Unique handle design, makes it easy and comfortable to floss. Removes trapped food debris.

Extra bristled pick for hard to get bits,even gets behind hard-to-reach molars.

Gently slides smooth between tight teeth. Freshen breath with flavor.

Recommends you use OK flosser after every meal and snack to have a fresher, cleaner mouth. For a completely daily clean, use with a OK flosser to easily reach back teeth.

OEM SERVICE SMALL MOQ FACTORY PRICE HIGH QUALITY INTERNATIONAL CERTIFICATE

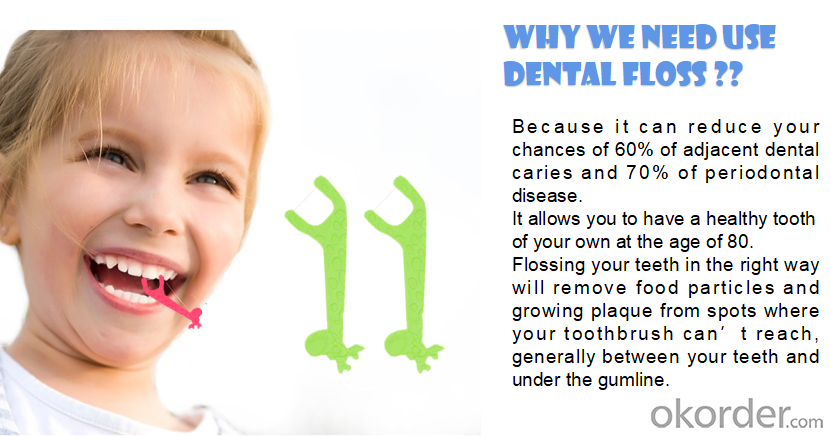

REDUCE ADJACENT DENTAL CARIES

DENTAL FLOSS FOR KIDS

FOOD-GRAD MATERIAL; FIBER FLOSS;MULBERRY SILK POLYACTIC ACID BAMBOO CHARCOAL

DENTAL FLOSS DETAILS & SIZE

100% BIODEGRADEBALE CORNSTRACH FLOSS PICK HANDLE;FUN SHAPES AND COLORS

Suggested use

Directions for flossing: While holding the handle, gently guide the floss between your teeth using a zig-zag motion. Move floss away from the gumline in a gentle back and forth, up and down motion alongside each tooth to remove food particles and plaque. Rinse floss as needed and repeat for each tooth.

Q: Can you accept OEM make?

A: Sure.We can make your customized brand and design blister card, inner box and master carton, and also pack as per your request.

2. Q: Where can I put my logo?

A: We can print your logo on the sticker, blister card, inner box and master carton.

3. Q: What are your MOQ?

A: Blister card packing: 10000 pcs/item.

Bulk packing: 5000 pcs/item.

4. Q: How can I get Samples?

A: Samples are free, while the shipping cost to be collected.

5. Q: What are your terms of payment?

A: 1) T/T(30% in advance, the balance by the copy of B/L).

2)For small order less than USD 3000, in order to save bank commision for both of us, we need 100% in advance.

6. Q: How long is the delivery time?

A: For the MOQ, the leading time is about 20-30 days.

- Q: What are the advancements in self-lubricating medical plastic?

- Self-lubricating medical plastics have seen several advancements in recent years. One significant advancement is the development of polymer composites with embedded lubricious particles, such as nanoparticles or microspheres. These particles can provide a durable and long-lasting lubricating effect, reducing friction and wear in medical devices. Additionally, the incorporation of hydrogel coatings on medical plastics has also shown promising results in improving lubrication properties. These advancements aim to enhance the performance and longevity of medical devices, reduce the need for additional lubricants, and improve patient comfort during medical procedures.

- Q: What is the shelf life of medical plastics?

- The shelf life of medical plastics can vary depending on factors such as the type of plastic, the storage conditions, and the specific medical device or product. In general, medical plastics have a shelf life ranging from a few months to several years. However, it is important to follow the manufacturer's guidelines and recommendations for proper storage and handling to ensure optimal performance and safety.

- Q: What are the trends and advancements in medical plastic technology?

- Medical plastic technology has witnessed several trends and advancements in recent years. One major trend is the development of biocompatible plastics that are safe for use in the human body. These materials are extensively used in various medical applications such as implants, prosthetics, and drug delivery systems. Additionally, there has been a significant focus on the development of antimicrobial plastics that help prevent the spread of infections in healthcare settings. Moreover, advancements in 3D printing technology have revolutionized medical plastic manufacturing, enabling the production of complex and customized medical devices. Overall, the ongoing trends and advancements in medical plastic technology are driving innovation and improving patient care in the healthcare industry.

- Q: How does medical plastic contribute to cost savings in healthcare?

- Medical plastic contributes to cost savings in healthcare in several ways. Firstly, it is a lightweight and durable material that reduces transportation costs as it is easier to handle and ship compared to traditional materials. Secondly, medical plastic is often disposable, eliminating the need for expensive sterilization processes, reducing labor costs, and minimizing the risk of cross-contamination. Additionally, medical plastic is versatile and can be molded into various shapes, reducing the need for multiple components, simplifying assembly, and lowering production costs. Furthermore, plastic medical devices are often less expensive to manufacture than their metal or glass counterparts. All these factors combined make medical plastic a cost-effective solution for healthcare providers, ultimately contributing to overall cost savings in the healthcare industry.

- Q: How are medical plastics tested for safety and efficacy?

- Medical plastics are tested for safety and efficacy through a series of rigorous evaluations and assessments. These tests typically involve biocompatibility testing, where the materials are examined for potential adverse reactions when they come into contact with the body. Additionally, mechanical and physical tests are conducted to ensure the materials are durable, resistant to wear and tear, and have the necessary strength and flexibility for their intended use. Furthermore, sterilization and packaging validation tests are performed to guarantee that the plastics maintain their properties and remain free from contaminants throughout their lifespan. These comprehensive testing procedures are crucial in ensuring that medical plastics meet the highest standards of safety and effectiveness before they are approved for use in healthcare settings.

- Q: Are medical plastics biodegradable?

- No, medical plastics are generally not biodegradable.

- Q: Are medical plastics UV resistant?

- Yes, medical plastics can be made UV resistant through the addition of UV stabilizers or by using plastic materials that inherently possess UV resistance. This helps protect the integrity and durability of medical devices and equipment when exposed to UV radiation.

- Q: How do medical plastics contribute to the development of regenerative medicine?

- Medical plastics play a crucial role in the advancement of regenerative medicine by providing a versatile and customizable platform for various applications. These plastics can be engineered to mimic the properties of human tissues and organs, allowing for the creation of 3D scaffolds and implants that support tissue growth and regeneration. Additionally, medical plastics can be used to encapsulate and deliver drugs or growth factors to targeted areas, promoting the regeneration process. Their biocompatibility, sterilizability, and ease of fabrication make medical plastics an essential component in the development of regenerative medicine techniques and therapies.

- Q: Are there any regulations for the disposal of used medical plastic products?

- Yes, there are regulations in place for the disposal of used medical plastic products. These regulations vary from country to country, but they typically focus on ensuring proper handling, segregation, and disposal of medical plastic waste to prevent environmental contamination and protect public health.

- Q: How do medical plastics impact the cost of healthcare?

- Medical plastics can significantly impact the cost of healthcare in several ways. Firstly, the use of medical plastics in various devices and equipment improves patient safety and reduces the risk of infection, which ultimately leads to better healthcare outcomes. However, the production, sterilization, and disposal of medical plastics can be costly, thus contributing to the overall cost of healthcare. Additionally, the increasing demand for medical plastics due to advancements in medical technology can lead to higher prices, further impacting healthcare costs. Therefore, while medical plastics offer numerous benefits, their utilization does have a notable influence on the overall cost of healthcare.

Send your message to us

Children's Safe Flavoring Dental Floss Pick

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 box

- Supply Capability:

- 100000 box/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords