Portable Floss Roll Clean Environmentally Friendly Floss Roll For House

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Portable Floss roll clean environmentally friendly floss roll for house

Soft tape to ace the tight space

No break, no shred floss

Helps remove plaque between teeth

Helps prevent gingivitis between teeth

Unique handle design, makes it easy and comfortable to floss. Removes trapped food debris.

Extra bristled pick for hard to get bits,even gets behind hard-to-reach molars.

Gently slides smooth between tight teeth. Freshen breath with flavor.

Recommends you use OK flosser after every meal and snack to have a fresher, cleaner mouth. For a completely daily clean, use with a OK flosser to easily reach back teeth.

Brand OEM/Ok Floss

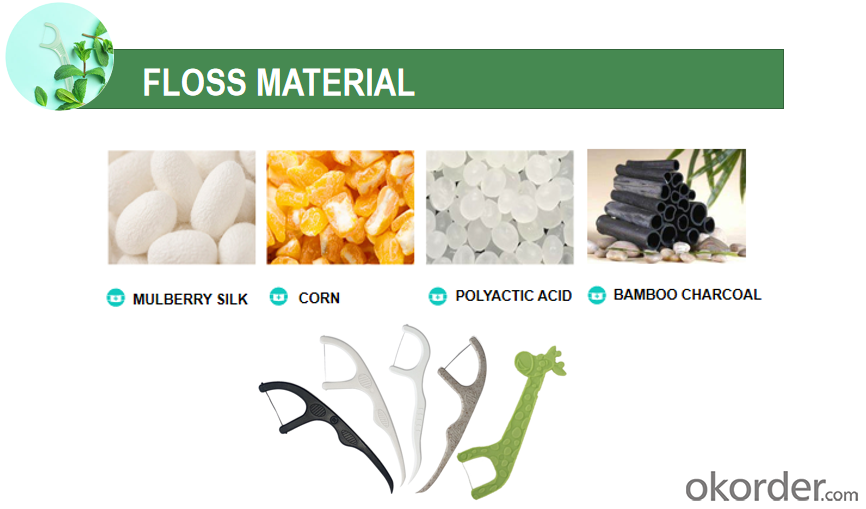

Floss materialCharcoal ,UHMWPE ,nylon

Floss length7.4*2.2cm/25-30M/OEM

WaxImport germany wax/american wax/bee wax/candelilla wax/customized wax

FlavorMint / green tea / lemon / peach / fruit / aloe / gin

ColorFloss original color

Floss original colorIndividual bulk PP bag/individual paper box/as customized

ApplicationsFamily,Hotel,Travel,Supermarket

DeliveryBy sea,By air,By express.

Lead time20-30days

Why we need use dental floss??

Because it can reduce your chances of 60% ofadjacent dental caries and 70% of periodontal disease.

It allows you to have a healthy tooth of your own at the age of 80.

Flossing your teeth in the right way will remove food particles and growing plaque from spots where your

toothbrush can’t reach, generally between your teeth and under the gumline.

Various flavors to choose:Mulberry Silk,Corn, Polyactic Acid, Bamboo Chacoal, and any flavor you want.

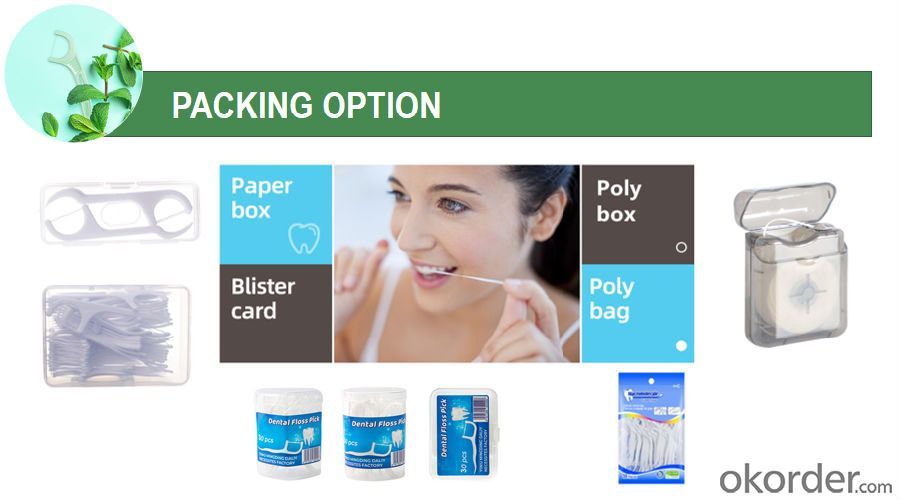

Many kinds of packaging options are available.

Suggested use

Directions for flossing: While holding the handle, gently guide the floss between your teeth using a zig-zag motion. Move floss away from the gumline in a gentle back and forth, up and down motion alongside each tooth to remove food particles and plaque. Rinse floss as needed and repeat for each tooth.

Warnings

Adult supervision recommended under age 10.

FAQ

Q: Can you accept OEMcan make your customize can make your customized brand and design blister card, inner box and master carton, and also pack as per your request.

2. Q: Where can I put my logo?

A: We can print your logo on the sticker, blister card, inner box and master carton.

3. Q: What are your MOQ?

A: Blister card packing: 10000 pcs/item.

Bulk packing: 5000 pcs/item.

4. Q: How can I get Samples?

A: Samples are free, while the shipping cost to be collected.

5. Q: What are your terms of payment?

A: 1) T/T(30% in advance, the balance by the copy of B/L).

2)For small order less than USD 3000, in order to save bank commision for both of us, we need 100% in advance.

6. Q: How long is the delivery time?

A: For the MOQ, the leading time is about 20-30 days.

- Q: How does the choice of medical plastic affect the performance of a medical device?

- The choice of medical plastic can significantly impact the performance of a medical device. Different types of medical plastics possess varying properties such as strength, flexibility, biocompatibility, and resistance to chemicals and sterilization methods. Selecting the appropriate medical plastic ensures that the device can withstand the intended use, maintain its structural integrity, and function effectively in the medical environment. A poor choice of medical plastic may lead to issues like material degradation, decreased durability, reduced functionality, or adverse reactions in patients. Therefore, careful consideration of the characteristics and suitability of medical plastics is crucial in designing and manufacturing high-performing medical devices.

- Q: How does medical plastic help in medical packaging?

- Medical plastic helps in medical packaging in several ways. Firstly, it provides a protective barrier that prevents contamination and ensures the sterility of medical devices and supplies. Medical plastic is also lightweight and durable, making it ideal for transport and storage of medical products. Additionally, plastic packaging can be easily molded into various shapes and sizes, allowing for efficient and customized packaging solutions. Furthermore, medical plastic is often transparent, allowing healthcare professionals to easily identify and monitor the contents of the package without opening it. Overall, medical plastic plays a crucial role in maintaining the safety, integrity, and convenience of medical packaging.

- Q: What is the difference between polyurethane and plastic?

- Rubber is made from latex, and a portion of the non - rubber contained in the latex is left in the solid rubber. In general, natural rubber contains 9, two,%-95% of rubber, not 5%-% of rubber hydrocarbons. Because of the different processing methods, different habitats and even different seasons, the proportion of these ingredients may vary, but basically within the scope. Proteins can promote the vulcanization of rubber and retard aging. On the other hand, the protein has strong water absorption, can cause rubber moisture absorption, mildew, insulation degradation, protein and increase heat generation shortcomings.

- Q: What are the challenges in recycling medical plastic?

- One of the main challenges in recycling medical plastic is the presence of biohazardous materials, such as blood or bodily fluids, which require specialized handling and disposal protocols. Additionally, medical plastics often contain additives or coatings that make the recycling process more complex. The wide variety of plastic types used in medical devices also poses a challenge, as different types may require different recycling methods. Furthermore, the stringent quality and sterility requirements of medical plastics can limit the ability to recycle them without compromising their safety and efficacy.

- Q: How is medical plastic used in gastroenterology applications?

- Medical plastic is used in gastroenterology applications in various ways. It is commonly used to manufacture endoscope accessories such as biopsy forceps, retrieval baskets, and stents. These plastic devices are designed to be flexible, durable, and biocompatible, allowing for safe and effective procedures within the gastrointestinal tract. Additionally, medical plastic is used in the production of medical tubing and catheters, which are essential for procedures like feeding tube insertion, colonoscopy, and gastric drainage. The use of medical plastic in gastroenterology applications ensures patient safety, ease of use for healthcare professionals, and optimal outcomes in the diagnosis and treatment of gastrointestinal disorders.

- Q: What are the challenges in designing medical plastic components?

- Designing medical plastic components presents several challenges, including ensuring biocompatibility, meeting strict regulatory requirements, incorporating complex geometries, maintaining dimensional accuracy, and considering the sterilization methods. Additionally, the components must be durable, resistant to chemicals, and able to withstand the rigorous demands of medical procedures and environments.

- Q: Can medical plastic be used in smart medical devices?

- Yes, medical plastic can be used in smart medical devices. Medical plastics are widely used in the healthcare industry due to their biocompatibility, durability, and versatility. They can be easily integrated into smart medical devices, allowing for advanced functionalities such as wireless connectivity, real-time monitoring, and data analysis. Additionally, medical plastics can be molded into complex shapes, making them suitable for various device designs.

- Q: How does medical plastic help in wound healing?

- Medical plastic helps in wound healing in several ways. Firstly, it provides a protective barrier that prevents external contaminants from entering the wound, reducing the risk of infection. Additionally, medical plastic dressings have properties that promote moisture balance, allowing the wound to stay moist, which is essential for optimal healing. These dressings also create an optimal environment for cell growth and proliferation, supporting the formation of new tissue. Moreover, medical plastic can be designed to be adhesive or non-adhesive, allowing for easy application and removal without causing further damage to the wound. Overall, medical plastic plays a crucial role in wound healing by providing a safe and conducive environment for the body's natural healing processes to occur.

- Q: Are all medical plastics safe for human use?

- No, not all medical plastics are safe for human use. While medical-grade plastics are specifically designed and tested to ensure safety, there can still be variations in the composition and manufacturing processes of different medical plastics. Some plastics may contain harmful substances or have properties that make them unsuitable for certain medical applications. Therefore, it is crucial to carefully select and evaluate medical plastics to ensure their safety and compatibility with human use.

- Q: Where can I find the exact material for jet writing? Plastic material

- Poly methyl PMMAPMMA can be used in aviation, aerospace, automobile, ship with bullet proof glass, window glass, instrument fittings, cockpit cover, lights, lights, optical instruments, such as glasses, magnifier and various lens.

Send your message to us

Portable Floss Roll Clean Environmentally Friendly Floss Roll For House

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords