Dental Floss Durable Portable Hygienic Cleanliness Restaurant Household Flossing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Dental Floss Durable Portable Hygienic Cleanliness Restaurant Household Flossing

Brand OEM/Ok Floss

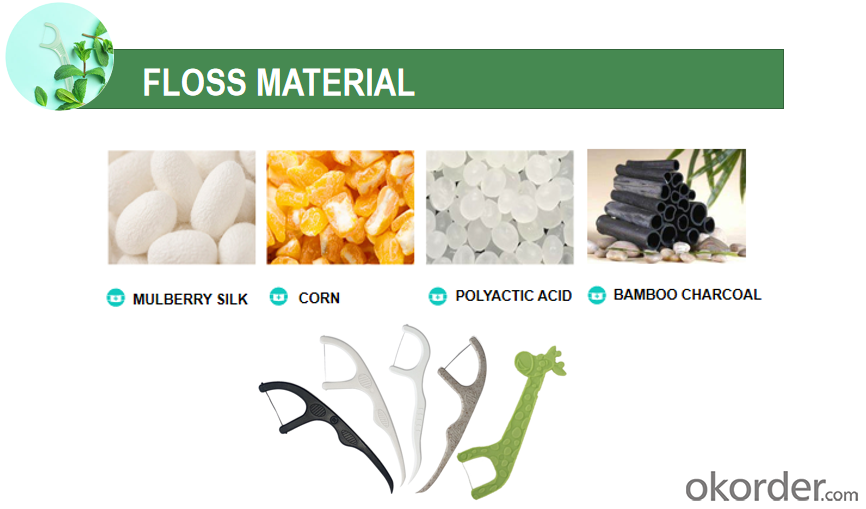

Floss materialCharcoal ,UHMWPE ,nylon

Floss length7.4*2.2cm/25-30M/OEM

WaxImport germany wax/american wax/bee wax/candelilla wax/customized wax

FlavorMint / green tea / lemon / peach / fruit / aloe / gin

ColorFloss original color

Floss original colorIndividual bulk PP bag/individual paper box/as customized

ApplicationsFamily,Hotel,Travel,Supermarket

DeliveryBy sea,By air,By express.

Lead time20-30days

No break, no shred floss

Helps remove plaque between teeth

Helps prevent gingivitis between teeth

Unique handle design, makes it easy and comfortable to floss. Removes trapped food debris.

Extra bristled pick for hard to get bits,even gets behind hard-to-reach molars.

Gently slides smooth between tight teeth. Freshen breath with flavor.

Recommends you use OK flosser after every meal and snack to have a fresher, cleaner mouth. For a completely daily clean, use with a OK flosser to easily reach back teeth.

Why we need use dental floss??

Because it can reduce your chances of 60% ofadjacent dental caries and 70% of periodontal disease.

It allows you to have a healthy tooth of your own at the age of 80.

Flossing your teeth in the right way will remove food particles and growing plaque from spots where your

toothbrush can’t reach, generally between your teeth and under the gumline.

Various flavors to choose:Mulberry Silk,Corn, Polyactic Acid, Bamboo Chacoal, and any flavor you want.

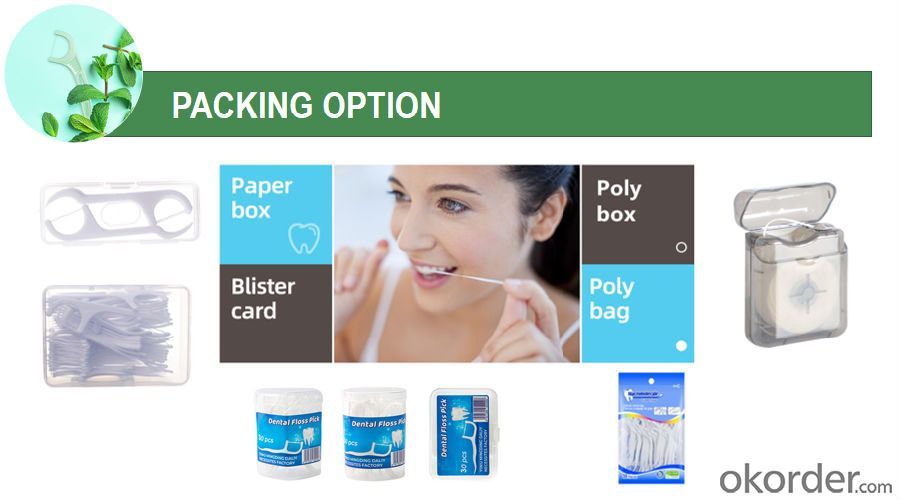

Many kinds of packaging options are available.

Suggested use

Directions for flossing: While holding the handle, gently guide the floss between your teeth using a zig-zag motion. Move floss away from the gumline in a gentle back and forth, up and down motion alongside each tooth to remove food particles and plaque. Rinse floss as needed and repeat for each tooth.

Warnings

Adult supervision recommended under age 10.

FAQ

Q: Can you accept OEMcan make your customize can make your customized brand and design blister card, inner box and master carton, and also pack as per your request.

2. Q: Where can I put my logo?

A: We can print your logo on the sticker, blister card, inner box and master carton.

3. Q: What are your MOQ?

A: Blister card packing: 10000 pcs/item.

Bulk packing: 5000 pcs/item.

4. Q: How can I get Samples?

A: Samples are free, while the shipping cost to be collected.

5. Q: What are your terms of payment?

A: 1) T/T(30% in advance, the balance by the copy of B/L).

2)For small order less than USD 3000, in order to save bank commision for both of us, we need 100% in advance.

6. Q: How long is the delivery time?

A: For the MOQ, the leading time is about 20-30 days.

- Q: Can Fuji medical dry imager 3500 print thermal sensitive film?

- Fuji medical dry imager 3500 can print thermal film.The thermosensitive film is a new and advanced technology, which is intended to replace the traditional plastic medical film used in hospitals

- Q: Can medical plastic be safely used in audiology applications?

- Yes, medical plastic can be safely used in audiology applications. Medical plastics are specifically designed and tested to meet strict safety and biocompatibility standards. They are resistant to chemicals and bacteria, making them suitable for use in audiology devices like hearing aids, ear molds, and other accessories.

- Q: Are medical plastics resistant to degradation?

- Yes, medical plastics are designed to be highly resistant to degradation. They are specifically formulated to withstand the harsh conditions typically encountered in medical settings, such as exposure to chemicals, heat, and sterilization processes. This durability ensures that medical plastics can maintain their physical and chemical properties over time, making them suitable for long-term medical applications.

- Q: Are there any environmental concerns associated with medical plastics?

- Yes, there are several environmental concerns associated with medical plastics. One major concern is the improper disposal and accumulation of plastic waste, which can contribute to pollution and harm ecosystems. Additionally, the manufacturing process of medical plastics often involves the use of hazardous chemicals and energy-intensive processes, which can have negative impacts on the environment. Moreover, the slow decomposition of plastics can lead to long-term environmental contamination. Efforts are being made to address these concerns by promoting sustainable alternatives and improving recycling and waste management practices in the medical industry.

- Q: Are there any alternatives to using medical plastics in healthcare?

- Yes, there are alternatives to using medical plastics in healthcare. Some alternatives include utilizing bio-based materials, such as biodegradable polymers derived from renewable resources like cornstarch or algae. Additionally, materials like glass, metals, and ceramics can be used in certain medical applications. Researchers are also exploring the use of 3D-printed implants and scaffolds made from natural materials like collagen. These alternatives aim to reduce the environmental impact of medical waste and minimize potential health risks associated with certain plastics.

- Q: How does medical plastic contribute to the development of tele-dentistry technologies?

- Medical plastic plays a crucial role in the development of tele-dentistry technologies by providing the necessary materials for the production of various dental tools and devices. These plastics are lightweight, durable, and compatible with sterilization methods, making them ideal for manufacturing items like dental cameras, intraoral scanners, and mouthguards used in tele-dentistry. Additionally, medical plastics enable the creation of reliable and portable dental equipment, facilitating remote consultations and oral health assessments, thereby expanding access to dental care for individuals who may not have easy access to in-person visits.

- Q: How is medical plastic used in tissue engineering and regenerative medicine?

- Medical plastic is extensively used in tissue engineering and regenerative medicine due to its unique properties and versatility. It is used to create scaffolds, which act as a framework for cells to grow and regenerate damaged tissues. These scaffolds can be designed to mimic the structure and properties of natural tissues, promoting cell adhesion, proliferation, and differentiation. Medical plastics also facilitate the controlled release of growth factors and therapeutic agents, aiding in tissue regeneration. Additionally, they can be engineered to be biocompatible, biodegradable, and porous, allowing for better integration with the surrounding tissues and ultimately supporting the development of functional and fully regenerated organs.

- Q: Smash PVC plastic and wear any mask

- Using SecureFit patented technology, through adjusting to adapt to different faces, to achieve a high fit. At the same time, the six points support the spread of pressure, the face no trace, very comfortable to wear.

- Q: Are there any regulations regarding the labeling of medical plastics?

- Yes, there are regulations regarding the labeling of medical plastics. These regulations ensure that medical plastics are properly labeled to provide necessary information such as product identification, manufacturer details, sterilization instructions, and any specific warnings or precautions. These regulations aim to promote patient safety and ensure the proper use and handling of medical plastics in healthcare settings.

- Q: How do medical plastics contribute to infection control in healthcare settings?

- Medical plastics play a vital role in infection control in healthcare settings by offering several key benefits. Firstly, they provide a barrier between the patient and the environment, minimizing the risk of cross-contamination. Medical plastics are easy to clean and disinfect, ensuring a hygienic environment for both patients and healthcare professionals. Additionally, these plastics are often disposable, reducing the chances of reusing contaminated materials. Their versatility allows for the creation of various medical devices that can be sterilized and used in surgical procedures, further preventing infections. Overall, medical plastics contribute significantly to infection control by promoting cleanliness, sterility, and the elimination of infection sources.

Send your message to us

Dental Floss Durable Portable Hygienic Cleanliness Restaurant Household Flossing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches