Dental floss with flavor of land animal shape suitable for children

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 box

- Supply Capability:

- 100000 box/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Dental floss with flavor of land animal shape suitable for children

FLOSS FOR KIDS

| Brand: | OEM/Ok |

| Floss materia: | UHMWPE,Charcal as customized |

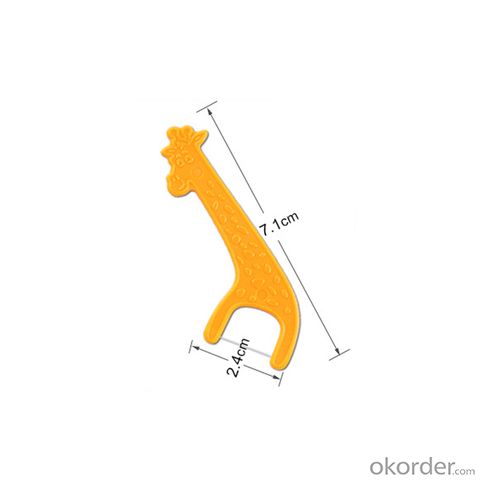

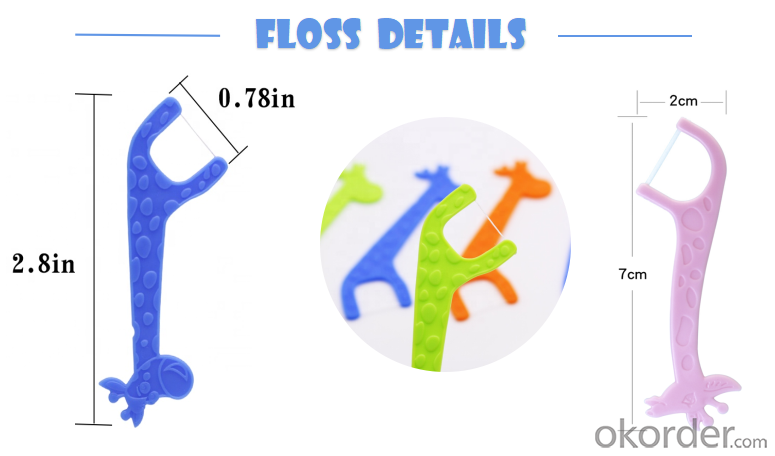

| Size | Length: 7.5cm |

| Wax | Import germany wax/american wax/bee wax/candelilla wax/customized wax |

| Flavor | Flavor |

| Color | yellow,white,blue,black |

| Floss original color | Individual bulk PP bag/individual paper box/as customized |

| Applications | Family,Hotel,Travel,Supermarket |

| Shape | Bear,Giraffe,Cola |

Lead time | 20-30days |

Soft tape to ace the tight space

No break, no shred floss

Helps remove plaque between teeth

Helps prevent gingivitis between teeth

Unique handle design, makes it easy and comfortable to floss. Removes trapped food debris.

Extra bristled pick for hard to get bits,even gets behind hard-to-reach molars.

Gently slides smooth between tight teeth. Freshen breath with flavor.

Recommends you use OK flosser after every meal and snack to have a fresher, cleaner mouth. For a completely daily clean, use with a OK flosser to easily reach back teeth.

OEM SERVICE SMALL MOQ FACTORY PRICE HIGH QUALITY INTERNATIONAL CERTIFICATE

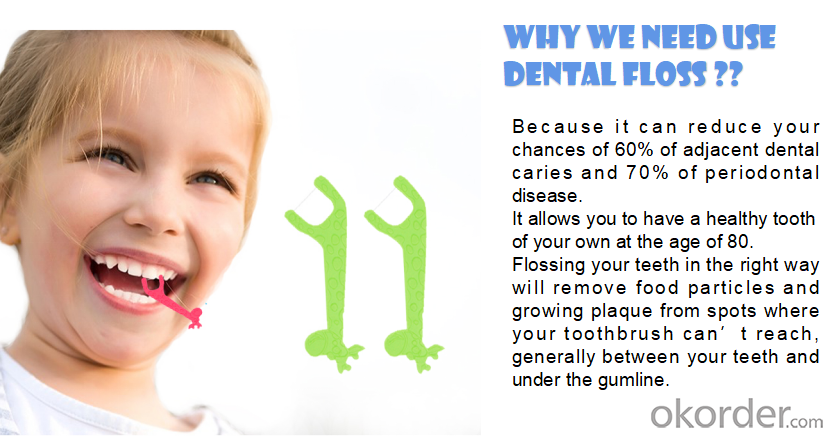

REDUCE ADJACENT DENTAL CARIES

FOOD-GRAD MATERIAL; FIBER FLOSS;MULBERRY SILK POLYACTIC ACID BAMBOO CHARCOAL

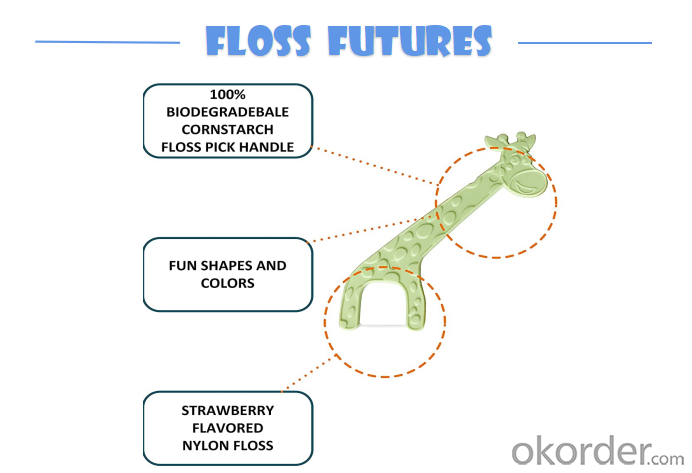

100% BIODEGRADEBALE CORNSTRACH FLOSS PICK HANDLE;FUN SHAPES AND COLORS STRAWBERRY FLAVORED NYLON FLOSS

Easilly slips between teeth ,without shredding, to comfortably remove plaque and help prevent gum disease

&

Good looking design protect children to hurt themselves

DENTAL FLOSS DETAILS & SIZE

COMFORT HANDLE;FOOD-GRAD MATERIALL;DENTAL FOR KIDS;FIBER FLOSS

DENTAL FOR KIDS

FACTORY PRICE & OEM

CERTIFICATIONS FDA CE ISO FSC

DENTAL FLOSS

GLOBAL MARKETING SERVICES

&

LOGISTIC SERVICE

&

EXPORT CREDIT INSURANCE SERVICES

&

FINANCIAL SERVICES

Q: Can you accept OEM make?

A: Sure.We can make your customized brand and design blister card, inner box and master carton, and also pack as per your request.

2. Q: Where can I put my logo?

A: We can print your logo on the sticker, blister card, inner box and master carton.

3. Q: What are your MOQ?

A: Blister card packing: 10000 pcs/item.

Bulk packing: 5000 pcs/item.

4. Q: How can I get Samples?

A: Samples are free, while the shipping cost to be collected.

5. Q: What are your terms of payment?

A: 1) T/T(30% in advance, the balance by the copy of B/L).

2)For small order less than USD 3000, in order to save bank commision for both of us, we need 100% in advance.

6. Q: How long is the delivery time?

A: For the MOQ, the leading time is about 20-30 days.

Suggested use

Directions for flossing: While holding the handle, gently guide the floss between your teeth using a zig-zag motion. Move floss away from the gumline in a gentle back and forth, up and down motion alongside each tooth to remove food particles and plaque. Rinse floss as needed and repeat for each tooth.

Warnings

Adult supervision recommended under age 10.

- Q: What plastics can be used in pharmaceutical packaging?

- PET (polyethylene terephthalate) was originally used as artificial fibres, films, tapes, etc., and was only used in beverage bottles in 1976. Using PET as a raw material for filling a container, is commonly known as the "bottle". Excellent hardness and toughness of plastic bottles, light weight (only the weight of glass bottles of 1/9 ~ 1/15), convenient to carry and use less energy consumption, production, and airtight, non-volatile, acid and alkali, is a carbonated beverage pack material. In recent years become carbonated drinks, tea, fruit juice, bottled water, wine and soy sauce and other products of filled containers, in addition, packaging bottles such as cleaning agent, shampoo, food oil, spices, sweet food, medicines, cosmetics, and alcoholic beverages, have been widely used in plastic bottles. Material transparency.Two, HDPE (HDPE), plastic, cleaning products, bath products

- Q: What are the considerations while selecting medical plastics for specific applications?

- When selecting medical plastics for specific applications, several considerations should be taken into account. Firstly, the biocompatibility of the plastic is crucial to ensure it does not cause any adverse reactions or harm to the patient. Additionally, the mechanical properties of the plastic, such as strength and flexibility, need to be suitable for the intended use. Chemical resistance is another important factor, as the plastic should not react with any drugs or substances it may come into contact with. Sterilization methods and compatibility with different sterilization processes should also be considered. Finally, cost-effectiveness and the ability to manufacture the plastic into the desired shape and size should be evaluated.

- Q: How is medical plastic used in surgical implants?

- Medical plastic is commonly used in surgical implants due to its biocompatibility, durability, and versatility. It is used to create various components of implants such as screws, plates, and joints. These implants are designed to replace damaged or diseased body parts, providing support and restoring functionality. The use of medical plastic in surgical implants helps to minimize the risk of rejection or allergic reactions, and it also allows for better customization and ease of surgical placement.

- Q: What are the chemical resistance properties of medical plastic?

- Medical plastics have excellent chemical resistance properties, which allow them to withstand exposure to a wide range of chemicals, including disinfectants, cleaning agents, and various pharmaceutical substances. This resistance helps prevent the degradation or leaching of harmful substances into medical devices or medications, ensuring their safety and efficacy. Additionally, medical plastics are often designed to be biocompatible, meaning they do not cause any adverse reactions when in contact with the human body. Overall, the chemical resistance properties of medical plastics play a crucial role in maintaining the integrity and functionality of medical equipment and devices.

- Q: How are medical plastics used in wound closure devices?

- Medical plastics are commonly used in wound closure devices such as sutures, staples, and adhesive strips. They provide strength, flexibility, and biocompatibility, allowing for effective wound closure and healing. These plastics are specifically designed to be sterile, easy to handle, and safe for use within the human body.

- Q: Smash PVC plastic and wear any mask

- Using SecureFit patented technology, through adjusting to adapt to different faces, to achieve a high fit. At the same time, the six points support the spread of pressure, the face no trace, very comfortable to wear.

- Q: Can we use black plastic bags for medical waste?

- Plastic bags for medical waste are not related to the color of plastic bags. In other words, plastic bags of any color can be used to hold medical waste.

- Q: Is there any way to wipe off the paint on the plastic?

- Plastic pigment can be used in a variety of organic solvents such as alcohol wipe, solvent oil, gasoline, methanol, ethyl acetate, days that water, open water, toluene, acetone, butanone, etc., but these are not easy to get, you can try to use toothpaste, glycerin, alcohol and try, because it can solve your problem.

- Q: Disposable plastic tablecloth, PEVA printed tablecloth, table cloth poisonous?

- Plastic is non-toxic, because plastics are large molecules, the body can not absorb. Only when the additives needed to be processed are poisonous or are not reacted at the time of synthesis, the small molecules are released in use, and the plastics show toxicity.

- Q: Where are the industrial refrigerators?

- Industrial freezers in plastic products (TV, computer, washing machine, mobile phone, refrigerator, air conditioning, plastic toys, automotive plastic parts and so on) of the injection molding process, can effectively and timely cooling (cooling), will directly affect the appearance and shape of the light passing rate, thus affecting the consumption efficiency, cost and effect of enterprises profit. The consumption of plastic containers (blowing bottles) and packaging films can not be separated from refrigerators (ice chillers). Plastic containers in the process of consumption, such as can not be timely cooling and shaping, consumption of containers will not be full, uneven wall thickness, color is not bright, and even can not be formed, resulting in lower quality products. If no cold water (air) cooling molding is used in the packaging film consumption, the qualified product can not be consumed. Cold water (ice) supplied by a chiller (chiller) can not only greatly improve the quality of products, but also increase the efficiency of consumption.

Send your message to us

Dental floss with flavor of land animal shape suitable for children

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 box

- Supply Capability:

- 100000 box/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches