Long Lasting Insecticide Treated Mosquito Net for Africa

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 PCS

- Supply Capability:

- 1000000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

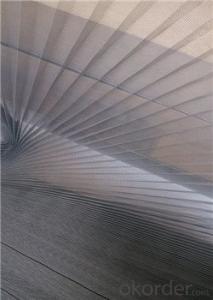

Introduction of Mosquito Net

This long lasting mosquito bed net is hooked on the ceiling and tucked under your mattress for overnight protection from bites. The deltamethrin treatment provides 4-5 years of protection, unlike permathrin which only lasts about 1 year. Insecticide treated mosquito nets, if used properly, are one of the best ways to prevent mosquitoes from biting and infecting individuals with malaria and other mosquito-borne diseases.

Details of Mosquito Net :

Lasts 4-5 years

Suitable for beds of all dimensions

For one or two people

Attaches to ceiling

Can be suspended from a ceiling

Pre-treated as per World Health Organization guidelines

Services of Mosquito Net :

Pre-sale services:

1.Various kinds of mosquito nets to choose from.

2.Any customized products can be satisfied according to your requirements.

3.Professional technicians engaged in each procedures.

Services during the sale:

1.Pre-checking and safeguarding products before delivery.

2.Providing solutions for any unexpected conditions involved.

After-sale services:

1.Assist customers on how to hang the exact mosquito nets.

2.Provided with instructions or vidoes of certain mosquito nets foldings.

3.24-hour Services.Contact us for any questions, we'd be gladly to follow.

Packaging & Delivery of Mosquito Net :

| Packaging Detail: | Individually packed into branded plastic bag,100 units per bale. |

| Delivery Detail: | 2 weeks after confirm order and payment |

FAQ of Mosquito Net:

1.Sample

We'd be gladly to send you the sample for free, but you need to pay for transport cost, and we will turn back this amount of money to you after orders issued.

2. MOQ

Our minimum order quantity for mosquito net is 1,000 pieces, and 500 kilograms for fleece fabric and mosquito net fabric.

3.Color, Size

Any color and any size is available as long as it's connected with mosquito nets.

- Q: What are the considerations for preventing allergic reactions to medical plastic?

- There are several considerations for preventing allergic reactions to medical plastic. Firstly, it is important to select hypoallergenic materials and avoid using plastics that contain common allergens such as latex. Secondly, proper sterilization techniques should be employed to eliminate any potential allergens or contaminants present on the plastic surfaces. Additionally, medical professionals should be vigilant in assessing a patient's medical history and conducting allergy tests to identify any known allergies that may contribute to an allergic reaction. Lastly, ensuring proper handling and storage of medical plastic products can minimize the risk of contamination and allergic reactions.

- Q: Can medical plastics be colored or tinted?

- Yes, medical plastics can be colored or tinted. This allows them to be easily identified for different medical purposes or to match specific branding requirements.

- Q: How do medical plastics contribute to the development of telehealth robotics?

- Medical plastics play a crucial role in the development of telehealth robotics by providing lightweight, durable, and sterile components that are essential for the construction of medical robots. These plastics enable the creation of intricate and precise robotic equipment, such as surgical robots and telepresence devices, that can be easily maneuvered and controlled remotely. Additionally, medical plastics have antimicrobial properties, ensuring a hygienic environment for both patients and medical professionals. Overall, medical plastics greatly contribute to the advancement of telehealth robotics, enhancing the efficiency, accessibility, and safety of remote healthcare delivery.

- Q: What are the factors to consider when selecting medical plastic for a specific application?

- When selecting medical plastic for a specific application, several factors need to be considered. These include the biocompatibility of the material, its mechanical properties and durability, chemical resistance, sterilization compatibility, and regulatory compliance. Additionally, factors such as cost-effectiveness, ease of processing, and availability of the material should also be taken into account during the selection process.

- Q: How can plastic cloth be glued to plastic steel windows?

- Glue is a substance that holds two objects together. Glue does not exist independently, it must be painted between two objects to play a bonding role. The chemical constituents of the glue, in the water environment. The polymer glue (vinyl acetate glue is a kind of oil derivatives) is a circular particle, the particle radius is generally between 0.5 ~ 5 m. The adhesion of an object is achieved by the tension between the polymer in the glue. In the glue, water is the carrier of the medium, and the water carries the polymer slowly into the tissue of the object. When the moisture in the glue has disappeared, the polymer in the glue will depend on the tension between them to combine the two objects together. In the use of glue, the amount of excessive coating will make the glue in the polymer bodies crowded together; high polymer can not produce a good tension. Polymers are so crowded that they do not form the strongest attraction of each other.

- Q: Plastic single screw precision medical pipe extruder

- Because of difference in design, there will be a co extruded tube, pipe, tube tip, pigtail catheters made after further processing.Medical grade extrusion because of its widely use, in the material, and relates to a medical grade material: Pebax®, Nylon (nylon), PC (polycarbonate), PP (polypropylene), TPU (thermoplastic polyurethane), PVC (polyvinyl chloride), fluorine plastic, PFA (soluble FEP (PTFE). Perfluorinated ethylene propylene copolymer), PTFE (PTFE), ETFE (ethylene tetrafluoroethylene copolymer), PE (polyethylene), HDPE (high density polyethylene), LDPE (low density polyethylene), PEEK.

- Q: What are the considerations for using medical plastic in drug discovery and development?

- When considering the use of medical plastic in drug discovery and development, several key considerations come into play. Firstly, the compatibility of the plastic with the drug substance needs to be assessed to ensure that it does not interact or degrade the drug during storage or administration. Additionally, the plastic material should be biocompatible and non-toxic to ensure patient safety. It is also important to evaluate the mechanical properties of the plastic such as strength, flexibility, and durability to ensure it can withstand the manufacturing processes and conditions of drug delivery systems. Lastly, the cost-effectiveness and scalability of the plastic material should be considered to ensure its feasibility for large-scale production. Overall, the selection of medical plastic requires careful evaluation of these factors to ensure the success and safety of drug discovery and development processes.

- Q: What are the most common uses of medical plastics in endocrinology?

- The most common uses of medical plastics in endocrinology include the production of insulin pens, hormone delivery devices, diagnostic test kits, and various medical implants such as insulin pumps and hormone-releasing intrauterine devices. These plastic-based medical devices play a crucial role in administering hormones, monitoring hormone levels, and managing endocrine disorders effectively.

- Q: Are medical plastics resistant to moisture?

- Yes, medical plastics are typically designed to be resistant to moisture. This is important in medical applications as it helps prevent the growth of bacteria and the degradation of the plastic's properties.

- Q: How is medical plastic used in healthcare?

- Medical plastic is used in healthcare for a wide range of applications, including medical devices, packaging materials, and even surgical instruments. It is a versatile material that is durable, lightweight, and can be easily sterilized, making it ideal for use in hospitals and clinics. Medical plastic is used to manufacture items such as syringes, IV tubes, catheters, prosthetics, and implants, enhancing patient care and facilitating various medical procedures. Additionally, it is crucial in maintaining a sterile environment by providing hygienic packaging for medications, dressings, and other medical supplies.

Send your message to us

Long Lasting Insecticide Treated Mosquito Net for Africa

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 PCS

- Supply Capability:

- 1000000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords