Dental Floss Bamboo Charcaol Food Grade ISO CE Tooth Floss

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 box

- Supply Capability:

- 100000 box/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Dental Floss Bamboo Charcaol Food Grade ISO CE Tooth Floss

| Brand | OEM/Ok Floss |

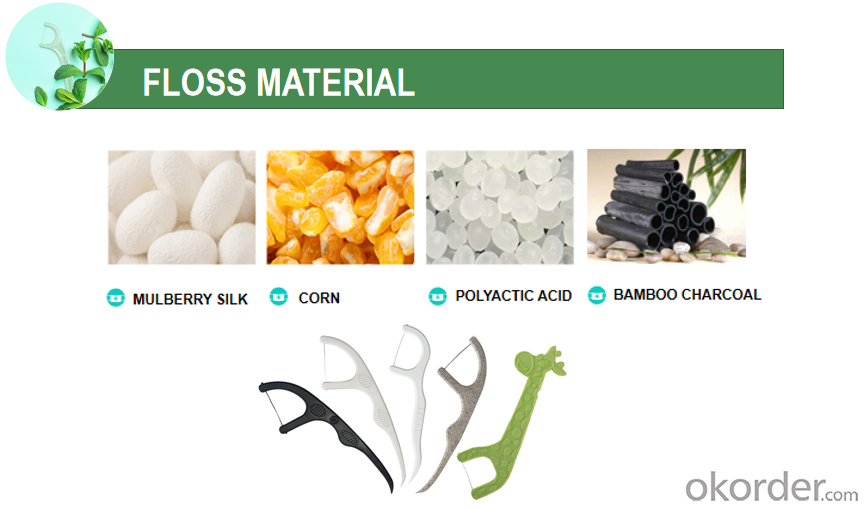

| Floss material | Bamboo Charcoal /OEM |

| Floss length | 7.4*2.2cm/OEM |

| Wax | Import germany wax/american wax/bee wax/candelilla wax/customized wax |

| Flavor | Mint / green tea / lemon / peach / fruit / aloe / gin |

| Color | Black |

| Floss original color | Individual bulk PP bag/individual paper box/as customized |

| Applications | Family,Hotel,Travel,Supermarket |

| Delivery | By sea,By air,By express. |

| Lead time | 20-30days |

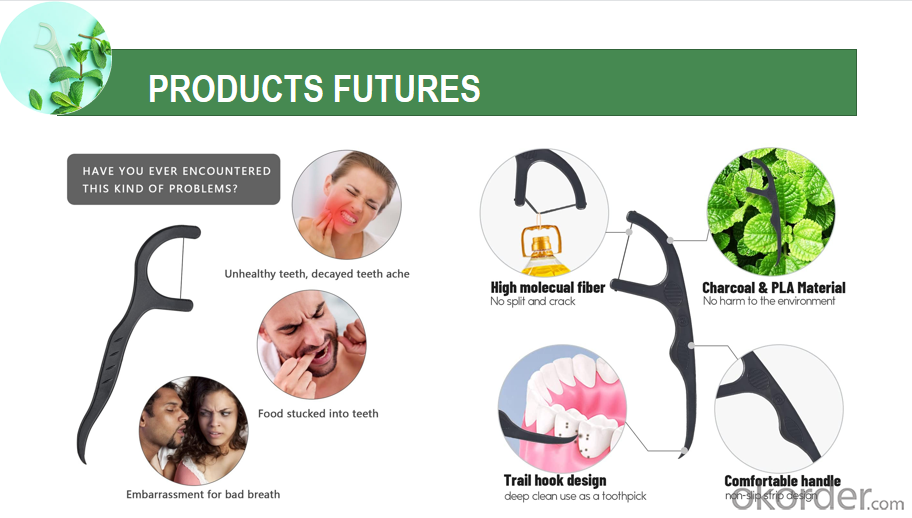

Soft tape to ace the tight space

No break, no shred floss

Helps remove plaque between teeth

Helps prevent gingivitis between teeth

Unique handle design, makes it easy and comfortable to floss. Removes trapped food debris.

Extra bristled pick for hard to get bits,even gets behind hard-to-reach molars.

Gently slides smooth between tight teeth. Freshen breath with flavor.

Recommends you use OK flosser after every meal and snack to have a fresher, cleaner mouth. For a completely daily clean, use with a OK flosser to easily reach back teeth.

OK FLOSS HELP YOUR ORAL CARE PROFESSIONAL OEM/ODM PROVIDER

Why we need use dental floss??

Because it can reduce your chances of 60% of adjacent dental caries and 70% of periodontal disease. It allows you to have a healthy tooth of your own at

the age of 80.Flossing your teeth in the right way will remove food particles and growing plaque from spots where your toothbrush can’t reach, generally

between your teeth and under the gumline.

Suggested use

Directions for flossing: While holding the handle, gently guide the floss between your teeth using a zig-zag motion. Move floss away from the gumline in a gentle back and forth, up and down motion alongside each tooth to remove food particles and plaque. Rinse floss as needed and repeat for each tooth.

Warnings

Adult supervision recommended under age 10.

FAQ

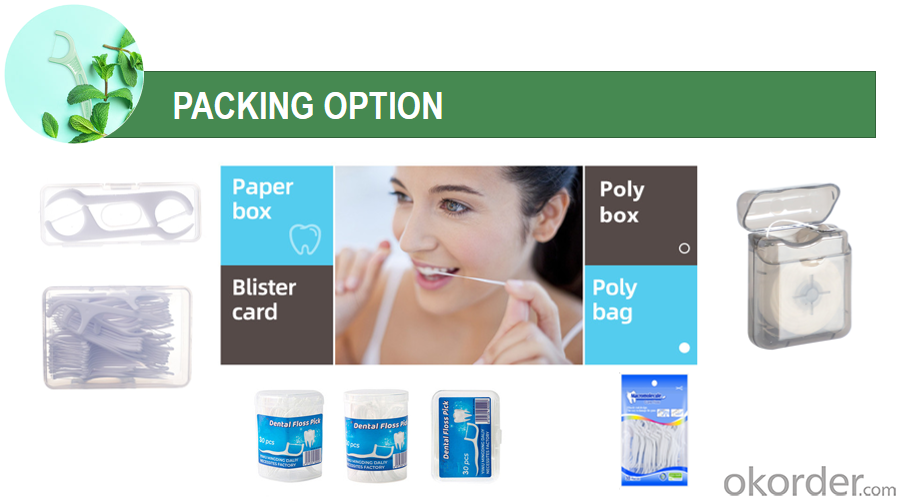

Q: Can you accept OEM make?

A: Sure.We can make your customized brand and design blister card, inner box and master carton, and also pack as per your request.

2. Q: Where can I put my logo?

A: We can print your logo on the sticker, blister card, inner box and master carton.

3. Q: What are your MOQ?

A: Blister card packing: 10000 pcs/item.

Bulk packing: 5000 pcs/item.

4. Q: How can I get Samples?

A: Samples are free, while the shipping cost to be collected.

5. Q: What are your terms of payment?

A: 1) T/T(30% in advance, the balance by the copy of B/L).

2)For small order less than USD 3000, in order to save bank commision for both of us, we need 100% in advance.

6. Q: How long is the delivery time?

A: For the MOQ, the leading time is about 20-30 days.

- Q: Can medical plastics be used in dermatology applications?

- Yes, medical plastics can be used in dermatology applications. They are commonly utilized in various dermatological procedures and treatments such as wound dressings, surgical instruments, cosmetic surgery implants, and drug delivery systems. Medical plastics offer advantages such as biocompatibility, flexibility, and durability, making them suitable for dermatology applications.

- Q: Are hard PVC plastic particles dangerous products? Are there any restrictions on imports from the United States (customs, commodity inspection)?

- Chinese from September 29th, forty-eighth in 2009, the Ministry of Commerce in 2003 fifty-third announcement, originating in the United States, South Korea, Japan, Russia and Taiwan imports of PVC (customs encoding 39041090) anti-dumping measures, the implementation period of five years. I did not find that the product (39042200) whether to levy anti-dumping duties related news, it is recommended to consult your local customs.

- Q: Are there any potential risks associated with the release of toxic fumes from medical plastics?

- Yes, there are potential risks associated with the release of toxic fumes from medical plastics. Exposure to these fumes can lead to respiratory irritation, allergic reactions, and in some cases, long-term health complications. It is crucial to ensure proper ventilation and use of appropriate safety measures when handling or disposing of medical plastics to minimize these risks.

- Q: What are the considerations for selecting biocompatible medical plastic materials?

- When selecting biocompatible medical plastic materials, there are several key considerations to keep in mind. These include the material's biocompatibility, sterilization compatibility, chemical resistance, mechanical properties, and manufacturing feasibility. Biocompatibility ensures that the material does not elicit any adverse reactions when in contact with living tissues or bodily fluids. Sterilization compatibility is important to ensure the material can withstand various sterilization methods without degradation. Chemical resistance ensures the material can resist exposure to common disinfectants, drugs, and bodily fluids. Mechanical properties such as strength, flexibility, and durability are vital for the intended medical application. Lastly, manufacturing feasibility considers factors like cost, availability, and the ability to mold or shape the material into the desired medical device or component. Overall, selecting biocompatible medical plastic materials requires careful evaluation of these considerations to ensure the safety and effectiveness of the final product.

- Q: How does medical plastic contribute to the development of bioreactors?

- Medical plastic plays a crucial role in the development of bioreactors by providing a sterile and biocompatible environment for cell cultures. It allows for the controlled growth and expansion of cells, facilitating various applications such as tissue engineering, drug testing, and regenerative medicine. Additionally, medical plastic offers flexibility in design, allowing for the creation of complex structures and channels within bioreactors that enhance nutrient and waste exchange, ensuring optimal cell growth and functionality.

- Q: Can medical catheters only be made of plastic?

- The chemical and physical properties of thermoplastic PA6 are similar to those of PA66. It has a lower melting point and a wide range of process temperatures. Melting temperature: 230~280C, for enhanced varieties of 250~280C. PA66 has a high melting point in polyamide materials. Melting temperature: 260~290C. The product of glass additive is 275~280C. The melting temperature shall be higher than 300C. And they add flame retardants, the melting temperature is increased, and the flame retardant effect is better. Often used for high breaking force automatic control electrical appliance shell and parts, such as AC contactor shell.

- Q: How do medical plastics help in reducing the risk of device failure during use?

- Medical plastics help in reducing the risk of device failure during use by offering excellent strength, flexibility, and durability. These materials are specifically designed to withstand the harsh conditions of medical environments, including exposure to chemicals, moisture, and high temperatures. Medical plastics also possess low friction properties, which prevent the accumulation of bacteria or other contaminants that can compromise the device's functionality. Additionally, these plastics can be molded into complex shapes, ensuring a precise fit and reducing the chance of mechanical failure.

- Q: How does medical plastic help in minimizing the risk of device-associated infections?

- Medical plastic helps in minimizing the risk of device-associated infections by its unique properties and design. It is a non-porous material that can be easily sterilized, preventing the growth and spread of harmful bacteria. Medical plastics also have antimicrobial properties, which further inhibit the growth of bacteria on the surface of medical devices. Additionally, plastic allows for the production of devices with smooth and seamless surfaces, reducing the chances of bacterial adherence and biofilm formation. These features make medical plastic a crucial component in reducing the risk of device-associated infections in healthcare settings.

- Q: Can medical plastic be sterilized?

- Yes, medical plastic can be sterilized using various methods such as steam, ethylene oxide gas, gamma radiation, or other sterilization techniques approved for medical devices.

- Q: Can medical plastic be safely used in urological applications?

- Yes, medical plastic can be safely used in urological applications. Medical grade plastics are specifically designed and tested to meet the stringent requirements of biocompatibility and safety. These plastics are known for their durability, flexibility, and resistance to chemicals, making them suitable for various urological devices such as catheters, stents, and implantable devices. Additionally, medical plastics are non-toxic, non-reactive, and do not cause allergic reactions, ensuring patient safety during urological procedures.

Send your message to us

Dental Floss Bamboo Charcaol Food Grade ISO CE Tooth Floss

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 box

- Supply Capability:

- 100000 box/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches