Barrier Fence Netting

Barrier Fence Netting Related Searches

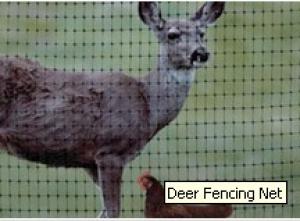

Protective Netting Scaffold Netting Plastic Garden Netting Fencing Flexible Netting Plastic Safety Netting Garden Screen Netting Plastic Deer Netting Black Plastic Garden Netting Garden Plastic Netting Plastic Wire Netting Clear Plastic Netting Green Plastic Netting Plastic Netting For Gardens Rigid Plastic Netting Poly Tube Netting Plastic Netting Nz Plastic Netting Uk Plastic Garden Netting Uk Vexar Netting Agricultural Netting Suppliers Pre Made Chain Link Fence Panels Plastic Mesh Deer Fencing Wrought Iron Fencing Wire Netting Prices Wire And Wood Fence Panels Synthetic Felt Roofing Heavy Duty Plastic Mesh Fencing Pvc Fencing Aluminum Fence Panels Cast Iron FenceBarrier Fence Netting Supplier & Manufacturer from China

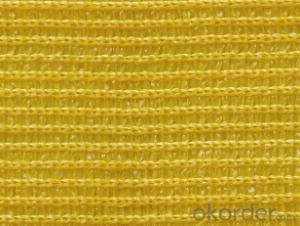

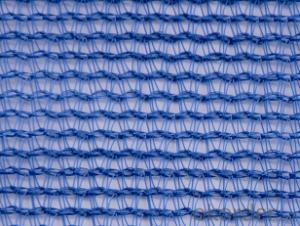

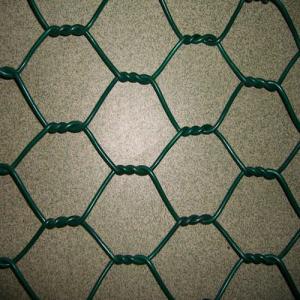

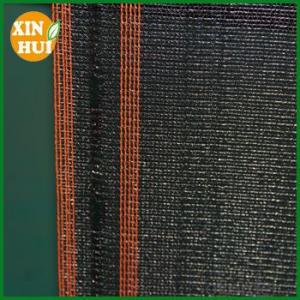

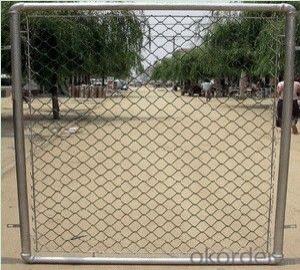

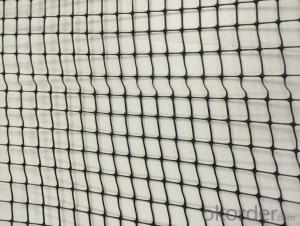

Barrier Fence Netting, a versatile and robust product, is widely used for various purposes such as construction sites, agricultural fields, and sports facilities. This type of netting serves as a protective barrier, preventing unauthorized access and ensuring safety in different environments. The product is designed to withstand harsh weather conditions and is known for its durability and strength, making it an ideal choice for long-term use.The application and usage scenarios of Barrier Fence Netting are vast, ranging from securing construction zones to safeguarding farmlands and sports arenas. It is particularly beneficial in areas where there is a need to control the movement of people or animals, or to protect valuable assets from potential damage. The netting can be easily installed and adjusted, providing a flexible solution for different situations. Its visual barrier effect also helps in deterring trespassers and maintaining privacy.

Okorder.com is a leading wholesale supplier of Barrier Fence Netting, boasting a large inventory that caters to the diverse needs of customers worldwide. The company prides itself on offering high-quality products at competitive prices, ensuring that clients receive the best value for their investment. With a commitment to customer satisfaction, Okorder.com is dedicated to providing excellent service and support, making it a reliable choice for those seeking Barrier Fence Netting for their projects or businesses.

Hot Products