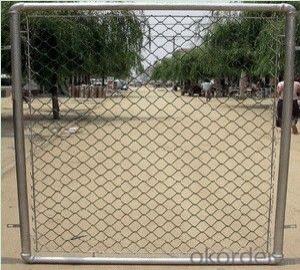

Common Chain Link Fence

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Type: | Place of Origin: | Hole Shape: | |||

| Model Number: | Frame Material: | Metal Type: | |||

| Pressure Treated Wood Type: | Frame Finishing: | Feature: | |||

| Item: | Material: | Assortment: | |||

| Mesh: | Wire dia: | Length: | |||

| Height: | zinc coating: | Color: | |||

Packaging & Delivery

| Packaging Detail: | woven bags in two edge of rolls |

| Delivery Detail: | 15-25days |

Specifications

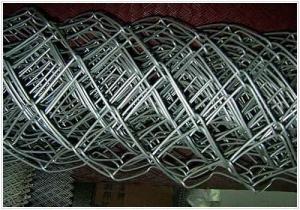

Chain link fence

1.Material: low carbon steel wire,stainless steel wire, PVC coated wire.

2.Wire dia 0.2mm~5.0mm

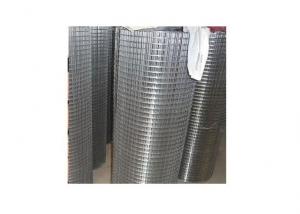

- Q: Can steel wire mesh be used for creating decorative ceilings or screens?

- Yes, steel wire mesh can be used for creating decorative ceilings or screens. Its durable and flexible nature allows for various design possibilities. The mesh can be shaped, manipulated, and installed to create unique and visually appealing patterns, textures, and shapes. Additionally, steel wire mesh offers a modern and industrial aesthetic, making it suitable for contemporary and urban designs.

- Q: Can steel wire mesh be used for sludge dewatering?

- Yes, steel wire mesh can be used for sludge dewatering. Steel wire mesh is a durable and strong material that can effectively retain solid particles while allowing water to pass through. When used for sludge dewatering, the mesh acts as a filter, separating the sludge from the water. As the sludge is pressed against the mesh, the water drains out, leaving behind a drier and more manageable sludge cake. Steel wire mesh is commonly used in various industries, such as wastewater treatment plants, mining, and construction, where sludge dewatering is necessary. It is important to choose the appropriate mesh size and material thickness based on the specific sludge characteristics and dewatering requirements to ensure optimal performance.

- Q: How is steel wire mesh used in the transportation industry?

- Steel wire mesh is commonly used in the transportation industry for various purposes. It is often used as reinforcement in tires to provide strength and durability. Additionally, it is used in the manufacturing of seat frames, car grilles, and other automotive components to enhance safety and structural integrity. The mesh is also used in cargo nets to secure goods during transportation, preventing them from shifting or falling off. Overall, steel wire mesh plays a crucial role in ensuring the performance, safety, and reliability of vehicles in the transportation industry.

- Q: Can steel wire mesh be used for creating safety barriers?

- Steel wire mesh is a suitable option for the creation of safety barriers. Known for its strength and durability, steel wire mesh is an ideal choice in situations where safety is of utmost importance. It finds utility in diverse settings, including construction sites, industrial facilities, sports venues, and highways. Employing steel wire mesh barriers effectively prevents unauthorized access, shields pedestrians from falling objects, and regulates vehicle movement. Moreover, these barriers are robust enough to endure adverse weather conditions and potential impacts. In addition, steel wire mesh barriers are cost-effective, require minimal maintenance, and can be easily installed and tailored to meet specific requirements. In conclusion, steel wire mesh is a dependable and adaptable material for the construction of safety barriers.

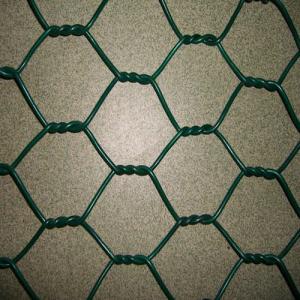

- Q: Can steel wire mesh be used for privacy fencing?

- Yes, steel wire mesh can be used for privacy fencing. It provides a durable and secure solution while still allowing some visibility. However, for enhanced privacy, additional materials or treatments may be required, such as adding privacy slats or using a double layer of mesh.

- Q: How is steel wire mesh used in reinforcement of power plants?

- Steel wire mesh is commonly used in the reinforcement of power plants for various purposes. One of the main uses of steel wire mesh is in the construction of concrete structures. Power plants often have high-stress areas that require reinforced concrete for added strength and durability. Steel wire mesh is embedded within the concrete to provide tensile strength and prevent cracking or structural failure. In power plants, steel wire mesh is also used for the reinforcement of walls and flooring systems. These areas are subject to heavy loads and vibrations, and steel wire mesh helps to distribute the load and enhance the overall structural integrity. By providing additional support, steel wire mesh helps to prevent the formation of cracks and ensures the longevity of the power plant's infrastructure. Additionally, steel wire mesh is used in the reinforcement of cooling towers and chimneys within power plants. Cooling towers are exposed to harsh environmental conditions, including extreme temperatures and moisture. Steel wire mesh helps to reinforce the concrete structures, making them more resistant to corrosion and damage. Furthermore, steel wire mesh is used in the reinforcement of power plant fences and security barriers. These structures are crucial for maintaining the safety and security of the power plant facility. Steel wire mesh is installed to create a strong and impenetrable barrier that prevents unauthorized access and protects the power plant from potential threats. Overall, steel wire mesh is an essential component in the reinforcement of power plants. It enhances the strength and durability of concrete structures, provides support for heavy loads and vibrations, protects against corrosion, and ensures the security of the facility. Its versatility and reliability make steel wire mesh an ideal choice for reinforcing various areas in power plants.

- Q: How does steel wire mesh perform in terms of resistance to weathering?

- Steel wire mesh is known for its exceptional resistance to weathering. Its composition, consisting of sturdy and corrosion-resistant steel, allows it to withstand various weather conditions such as rain, snow, heat, and UV exposure. Unlike other materials, steel wire mesh does not warp, crack, or degrade when exposed to these elements. The galvanization process further enhances its weather resistance. Galvanization involves coating the steel wire mesh with a layer of zinc, which acts as a barrier against moisture and prevents rusting. This additional layer makes the mesh even more durable and extends its lifespan. Steel wire mesh also performs well in terms of resistance to extreme temperatures. It does not become brittle in cold weather or lose its structural integrity in high temperatures. This makes it suitable for a wide range of applications, including outdoor fencing, construction projects, and agricultural uses. Furthermore, steel wire mesh is highly resistant to wind and impact. Its strong and flexible nature enables it to withstand strong gusts without bending or breaking. This makes it an ideal choice for applications where wind loads are a concern, such as in coastal areas or high-rise buildings. Overall, steel wire mesh is an excellent choice for outdoor applications due to its exceptional resistance to weathering. Its ability to withstand various weather conditions, galvanized coating, and resistance to extreme temperatures and wind make it a reliable and durable option for a wide range of projects.

- Q: Is steel wire mesh resistant to pests?

- Yes, steel wire mesh is resistant to pests. The tightly woven construction of the mesh makes it difficult for pests, such as insects or rodents, to pass through. This makes it an effective barrier against unwanted intruders in various applications, such as keeping pests out of gardens, protecting vents or windows from insects, or preventing small animals from entering a property. Additionally, steel wire mesh is durable and can withstand environmental factors, making it a long-lasting solution for pest control.

- Q: Can steel wire mesh be used for security fencing?

- Yes, steel wire mesh can be used for security fencing. Steel wire mesh is a strong and durable material that provides excellent security and protection. It is commonly used for various security applications such as perimeter fencing, residential fencing, commercial fencing, and even high-security areas like prisons and military facilities. The strength and rigidity of steel wire mesh make it highly resistant to cutting or tampering, making it an effective deterrent against unauthorized access or intrusion. Additionally, the small openings in the mesh design provide visibility while still maintaining a high level of security. Steel wire mesh is also versatile and can be customized to suit specific security requirements. It can be easily installed in different configurations, heights, and thicknesses to meet the specific needs of any security fencing project. Moreover, steel wire mesh can be galvanized or coated with anti-corrosion materials to enhance its lifespan and withstand harsh weather conditions. In summary, steel wire mesh is a reliable and effective choice for security fencing due to its strength, durability, versatility, and resistance to tampering. It provides a secure barrier while still allowing visibility, making it a popular option for numerous security applications.

- Q: Can steel wire mesh be used for automotive grilles?

- Automotive grilles can indeed utilize steel wire mesh. The reason behind its popularity in this application is its endurance, robustness, and ability to resist corrosion. It ensures the radiator and other vital parts of the vehicle remain safeguarded while facilitating sufficient air circulation. Moreover, steel wire mesh grilles are frequently employed for aesthetic reasons, as they enhance the overall look of the vehicle. What's more, installing and maintaining steel wire mesh is relatively effortless, rendering it a practical option for automotive grilles.

Send your message to us

Common Chain Link Fence

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords