Dental Flossing Eco Bamboo Charcoal Strong Teeth Floss Cleaner Picks

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 bag

- Supply Capability:

- 100000 bag/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Dental Flossing Eco Bamboo Charcoal Strong Teeth Floss Cleaner Picks

| Brand | OEM/Ok Floss |

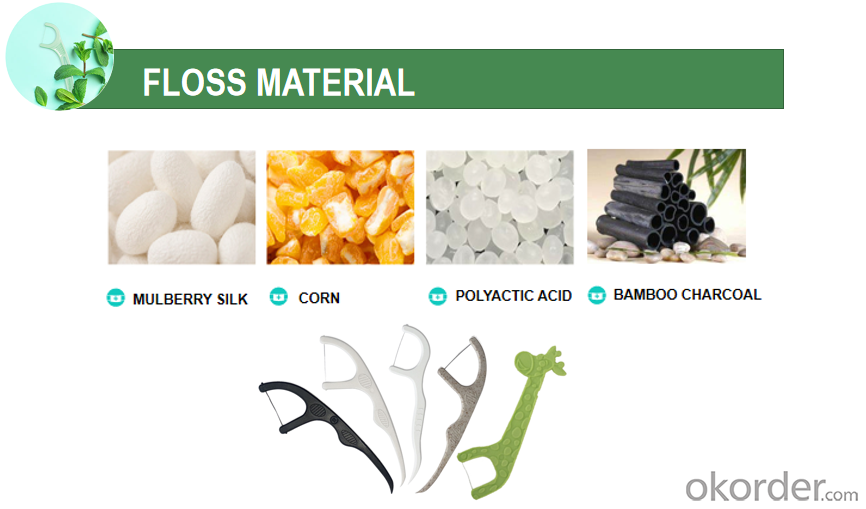

| Floss material | Charcoal ,UHMWPE ,nylon |

| Floss length | 7.4*2.2cm/25-30M/OEM |

| Wax | Import germany wax/american wax/bee wax/candelilla wax/customized wax |

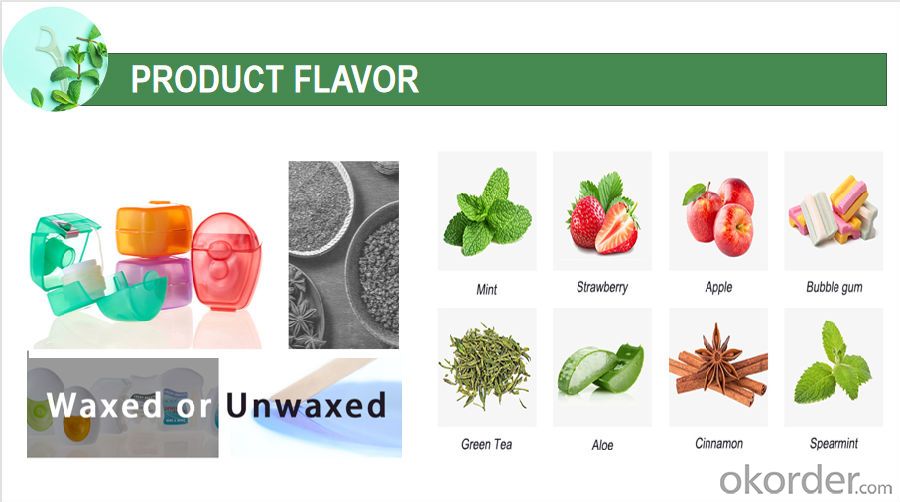

| Flavor | Mint / green tea / lemon / peach / fruit / aloe / gin |

| Color | Floss original color |

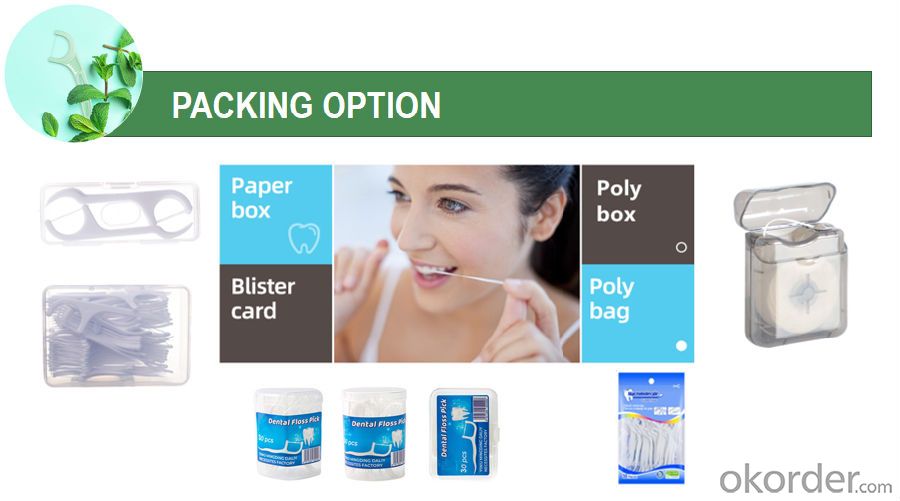

| Floss original color | Individual bulk PP bag/individual paper box/as customized |

| Applications | Family,Hotel,Travel,Supermarket |

| Delivery | By sea,By air,By express. |

| Lead time | 20-30days |

Soft tape to ace the tight space

No break, no shred floss

Helps remove plaque between teeth

Helps prevent gingivitis between teeth

Unique handle design, makes it easy and comfortable to floss. Removes trapped food debris.

Extra bristled pick for hard to get bits,even gets behind hard-to-reach molars.

Gently slides smooth between tight teeth. Freshen breath with flavor.

Recommends you use OK flosser after every meal and snack to have a fresher, cleaner mouth. For a completely daily clean, use with a OK flosser to easily reach back teeth.

Why we need use dental floss??

Because it can reduce your chances of 60% of adjacent dental caries and 70% of periodontal disease.

It allows you to have a healthy tooth of your own at the age of 80.Flossing your teeth in the right way will

remove food particles and growing plaque from spots where your toothbrush can’t reach, generally between

your teeth and under the gumline.

FAQ

Q: Can you accept OEM make?

A: Sure.We can make your customized brand and design blister card, inner box and master carton, and also pack as per your request.

2. Q: Where can I put my logo?

A: We can print your logo on the sticker, blister card, inner box and master carton.

3. Q: What are your MOQ?

A: Blister card packing: 10000 pcs/item.

Bulk packing: 5000 pcs/item.

4. Q: How can I get Samples?

A: Samples are free, while the shipping cost to be collected.

5. Q: What are your terms of payment?

A: 1) T/T(30% in advance, the balance by the copy of B/L).

2)For small order less than USD 3000, in order to save bank commision for both of us, we need 100% in advance.

6. Q: How long is the delivery time?

A: For the MOQ, the leading time is about 20-30 days.

Suggested use

Directions for flossing: While holding the handle, gently guide the floss between your teeth using a zig-zag motion. Move floss away from the gumline in a gentle back and forth, up and down motion alongside each tooth to remove food particles and plaque. Rinse floss as needed and repeat for each tooth.

Warnings

Adult supervision recommended under age 10.

- Q:How are medical plastics tested for quality and durability?

- Medical plastics are tested for quality and durability through rigorous testing methods such as mechanical testing, chemical resistance testing, biocompatibility testing, and long-term aging tests. These tests assess the strength, flexibility, impact resistance, chemical compatibility, and stability of medical plastics, ensuring they meet the required standards for use in medical devices and equipment.

- Q:Can medical plastics be used in drug delivery systems?

- Yes, medical plastics can be used in drug delivery systems. They are often used to manufacture various components of drug delivery devices, such as syringes, vials, and implantable devices. Medical plastics offer advantages like biocompatibility, durability, and ease of manufacturing, making them suitable for drug delivery applications. Additionally, they can be designed to be sterile, inert, and resistant to chemical interactions, ensuring the safe and effective delivery of medications to patients.

- Q:What are the considerations for using medical plastic in wearable infusion pumps?

- Some considerations for using medical plastic in wearable infusion pumps include biocompatibility, durability, flexibility, chemical resistance, and ease of manufacturing. Medical plastics must be safe for use within the body, ensuring they do not cause any adverse reactions or toxicity. They should also be durable enough to withstand constant use and movement without degradation or breakage. Flexibility is essential for wearable devices to conform to the body and provide comfort. Chemical resistance ensures that the plastic does not degrade when exposed to various medications or bodily fluids. Lastly, ease of manufacturing is crucial for mass production and cost-effectiveness.

- Q:How do medical plastics affect the weight of medical devices?

- Medical plastics can positively affect the weight of medical devices as they are lighter compared to traditional materials like metal. This allows for the development of lighter and more portable medical devices, which can enhance patient comfort and ease of use.

- Q:Can you tell me what kind of plastic material can be used in medical instruments?

- You need to add various additives in plastics processing or modification process, such as in the PVC medical products in the amount of the plasticizer is as high as 30 - 60%, so as far as possible the use of non-toxic additives, long-term use to prevent or reduce the additive precipitation, so as not to affect the product performance and the therapeutic effect;

- Q:What are the considerations for disposal of medical plastic products?

- There are several considerations for the disposal of medical plastic products. Firstly, it is important to ensure proper segregation and collection of these items to prevent them from ending up in regular waste streams. Medical plastic waste should be separated and disposed of separately to avoid any contamination or potential health risks. Secondly, proper disposal methods should be followed to minimize the environmental impact. This includes determining if the plastic products can be recycled, incinerated, or disposed of in a specialized landfill. Recycling is often preferred to reduce the strain on resources and minimize waste generation. Additionally, compliance with local regulations and guidelines is crucial. Different regions may have specific requirements for the disposal of medical plastic waste, such as specific labeling or documentation. Adhering to these regulations helps ensure safe and responsible disposal. Lastly, considering the potential for reuse or repurposing of medical plastic products is important. Some plastic items, such as containers or packaging, may be suitable for sterilization and reuse, reducing the need for new plastic production. Overall, the considerations for the disposal of medical plastic products revolve around proper segregation, environmentally friendly disposal methods, compliance with regulations, and exploring opportunities for reuse or repurposing.

- Q:How do medical plastics contribute to the development of personalized prosthetics?

- Medical plastics play a crucial role in the development of personalized prosthetics by offering a wide range of benefits. These materials are lightweight, durable, and easily moldable, allowing for the creation of customized prosthetic devices that perfectly fit an individual's unique anatomy and needs. Additionally, medical plastics provide excellent biocompatibility, meaning they are well-tolerated by the human body, reducing the risk of adverse reactions or complications. Their versatility also enables the integration of electronic components, sensors, and adjustable features into prosthetics, enhancing functionality and improving the overall user experience. Ultimately, medical plastics contribute to the advancement of personalized prosthetics by enabling the creation of comfortable, efficient, and tailor-made solutions for individuals with limb loss or disabilities.

- Q:What are the different sterilization methods for medical plastics?

- The different sterilization methods for medical plastics include steam sterilization, ethylene oxide (EtO) sterilization, gamma radiation sterilization, electron beam sterilization, and hydrogen peroxide gas plasma sterilization.

- Q:How is medical plastic used in genetic testing?

- Medical plastic is used in genetic testing to create various devices and tools that are essential for the collection, storage, and analysis of biological samples. These plastics are used to manufacture items such as test tubes, pipettes, DNA sequencing machines, microarray slides, and PCR plates, which are all crucial components in the genetic testing process. The use of medical plastic ensures the sterility, durability, and compatibility of these materials with the biological samples, allowing for accurate and reliable genetic testing results.

- Q:Can medical plastics be easily sterilized?

- Yes, medical plastics can be easily sterilized. They are designed to withstand various sterilization methods such as steam autoclaving, ethylene oxide gas sterilization, and gamma radiation. These methods effectively eliminate bacteria and other microorganisms, ensuring the safety and cleanliness of medical equipment and devices.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

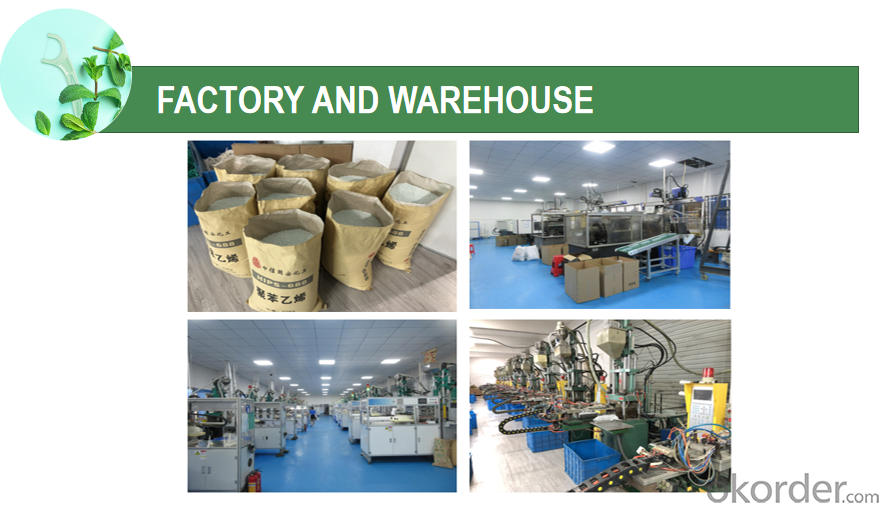

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Dental Flossing Eco Bamboo Charcoal Strong Teeth Floss Cleaner Picks

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 bag

- Supply Capability:

- 100000 bag/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords