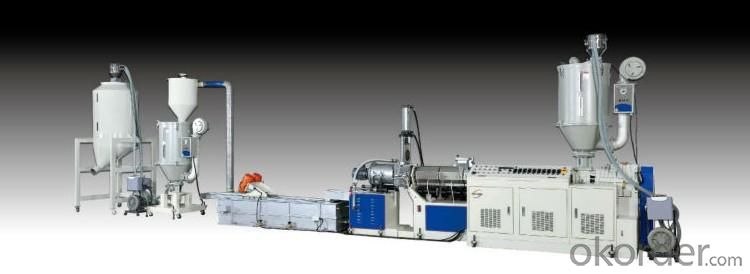

Waster Plastic Recycling Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set pc

- Supply Capability:

- 10 Sets Per Week pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

SJ-A wind-cooling Hot-cutting plastic Recycling Machine take HDPE,LDPE as the material,and make them into granules.

Name:SJ-A wind-cooling Hot-cutting plastic Recycling Machine

This raw materials like waste films of HDPE and LDPE are extruded through the extruder, and then are cooled through wind and cut hotly into granules, featuring in fine quality, bubble free and moisture free. The machine is equipped with a forced feeder, fast mesh changer and automatic rhermocontroller. Characteristics: Main Technical Variables

Main Technical Variables:

| Model | SJ-90 | SJ-100 | SJ-110 | SJ-120 |

| Type Diameter of Screw Stem | φ90 | φ100 | φ110 | φ120 |

| Major Diameter Ratio of Screw Stem (L/D) | L/D 201 -221 | L/D 201 -221 | L/D 201 -221 | L/D 201 -221 |

| Rational Speed of Screw Stem | 10-100r/min | 10-100r/min | 10-100r/min | 10-100r/min |

| Main Motor Power | 22kw | 30kw | 37kw | 45kw |

| Output | 68kg/h | 95kg/h | 120kg/h | 135kg/h |

| Weight of overall(kg) | 2600kg | 2800kg | 3000kg | 3200kg |

| Cover dimensions (l×w×h) (mm) | 4000×1500×1800 | 4000×1500×1800 | 4000×1500×1800 | 4600×1500×1800 |

- Q: What is the raw material used in the production of plastic products?

- The microwave oven lunch box is made of this kind of material. It is resistant to high temperature at 130 degrees and has poor transparency. It is the only plastic box which can be put into the microwave oven. It can be reused after careful cleaning. Particular attention should be paid to the fact that some microwave oven boxes are made of size 05, but the box cover is made of size 06 PS (polystyrene). PS has good transparency and is not high temperature resistant, so it can not be put into the microwave oven with the box body together. PP. For insurance purposes, put the container in front of the microwave oven and remove the lid first.

- Q: What is the difference between EPS plastic particles and PS? What materials are represented?

- PS does not have no foaming agent. It is divided into GPPS (ordinary type) and HIPS (impact type). It is used for injection molding, extrusion, television, telephone shell, cup and so on.The main ingredients are polystyrene.

- Q: What's the difference between recycled plastic bucket and plastic bucket made of raw material?

- The easiest way to do this is to press hard, see flexibility and bounce back. You can also cut off a small piece with a knife, lost in the water, can float is generally the new material is recycled sink. If PE is the plastic bucket, the recycled material is usually porcelain white, and the raw material should be translucent.

- Q: What material is good for plastic bellows?

- In the cases to recommend the use of PE (polyethylene) bellowsNo oxidizing acids, no environmental oils, vegetable oils, mineral oils, no organic solvents such as aliphatic hydrocarbons, aromatic hydrocarbons, ketones, esters, etc..Mainly used in the temperature range of -40 to 80 degrees Celsius environment; used in automobiles, motorcycles and other motor vehicle wire harness sheath; also used for household appliances, precision machine tools and other equipment wiring wire sheath.

- Q: How do you increase the transparency and hardness of PP plastic suction pipes? What raw materials do you need to add?

- First, the material selection should be correct. Generally speaking, it is better to choose PP with good transparency.

- Q: PVC what chemicals do you need for plastic surface treatment?

- The choice of surface treatment methods, because most of the plastic surface can be low, many processing methods, such as decoration, printing, spraying and so on, can not be directly applied, and the need for surface treatment first

- Q: How to test plastic raw materials?

- Sample appearance quality. The plastic raw material is produced according to the normal production process, and the appearance quality of 10~20 parts is observed. The sample product shall not be cracked, deformed, foamed, broken, expanded or shrunk, and other defects that affect appearance. Smooth surface and clear surface.

- Q: What are the raw materials for producing plastic films?

- Plastic film raw materials are: PVC, polyethylene, polypropylene, polystyrene and other resins.

- Q: Aluminum Alloy door corner with what plastic raw materials do?

- The best use of Ninon or ABS material. The two kinds of materials are both hard and hard to wear. However, these two materials, the higher prices.

- Q: Chemical, plastic raw materials, plastic raw materials how sub grade?

- That's because the raw material used for making plastic barrels is different. Just like the quality of the clothes, the grades of the fabrics used are different, and the products presented are definitely different.

1. Manufacturer Overview

| Location | Zhejiang,China (Mainland) |

| Year Established | 2009 |

| Annual Output Value | US$10 Million - US$50 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe |

| Company Certifications | CE Certificate; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | 1,000-3,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | |

Send your message to us

Waster Plastic Recycling Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set pc

- Supply Capability:

- 10 Sets Per Week pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords